Ukuziqonda Umphrinti Wesikreyni Ngokuhlanganiswa Kwegcino Elinenzulu

Yini Umphrinti Wesikreyni Onenxenye Yegcino Elinenzulu?

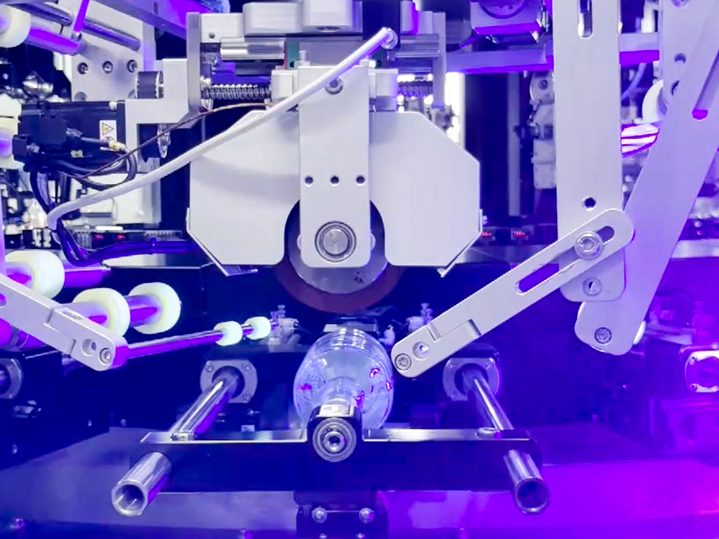

Abaphrinti besikrini abanamandla okugcwalisa ngokushushu bakhuthaza izindlela ezimbili zokugcina ekhanda ngendlela eyodwa. Isayensi yenza ngokuphrinta imiboniso emihlaza ngemithwalo yesikrini futhi ngokufanayo noma ngemuva kokufaka amafolo amadala noma amathambo angcono ngokushushu kwezimali. Okukhanya kula makhina kunazo zingaphandle kukuba zinezinhlelo zokubhalisa eziphakathi ezimenza konke kuhlambulukane kakade xa kusebenziswa kumathuba njengebokisi yokupaki, izinhlamvu zezigubhu, nezinye izinto zokumkakha. Abakhi kuthola lokhu kuhlanganiswa kungcolile kakhulu ngoba kususa izindiza zokwakha ngaphandle kokuchitha kumqondo wokuphuma kwesimeni.

Ukuthi Kanjani Ukuphrintwa Ngisikrini Nokugcwalisa Ngokushushu Kuyagcina Inkinga Yophrinti

Ukudibanisa lezi zindlela kwenza 43% kakhulu ingcindezi yobuciko (Ukupakisha i-Digest 2023) ngokulinganisa nokuphela kwezinye izikhathi. Izingqalobhizinzi zomthambeka waphansi kwamashini angcwele zihlangana neemathe emibhalweni engcweliswe, futhi izithuthi ezivimbela zongezela ubukhulu begrafu ephrintiwe. Indlela yombili isusa amadlimitsheli:

- Ukuprinta kwi-screen kuphela kusahwala nokufakwa okubonakalayo

- Umthambeka waphansi kwamashini angcwele ogcwele akwazi ukufaka imibala engavamile

Ukuqashwa kwezimali kakhulu 68% (2020–2023) njengoba izimfanelo ezifana nezinhlotshane zomdlalo nabezimali zokulima zidinga ukugcwalisa okubonakala kakhulu.

Izinqubo Ezibalulekile Zomkhumbi Wokuprinta Ngosihlalo Nenqubo Yothambeka Lwaphansi Kwamashini Angcwele

Izinhlelo ezihlanzekile ezinezinkinga ezinzima zilandelayo:

| Ingxenye | Isenzo | Impact Kakhulu Kokubona Kwegrafu |

|---|---|---|

| Izihlangothini zombili zokubhalwa | Ukulungisa iimbono zomgca kanye neezikhonkwane ze-foil ngaphakathi kwe ±0.1 mm | Ayisusi iziphumo ezingavumelekanga/iingxaki zokulungiswa |

| Iindlebe ezahlukene zokuthatha umthwalo | Igcine ubomi phakathi kuka-140–160°C ukuze kuqeqeshelwe ifoil | Ikhubaza ukususa umthwalo ngaphambi kokuqala |

| Izixhobo zokunika ink/foil ezihlawulisayo | Zinikeza i-UV inks kanye neefoil ngokufanayo | Isusa ukuphatha isiqhamo ngo-75% |

Le miqondo ihlala yenza ngapriorithi ubunjingili bwezihloko , ihlawula izinto ukusuka kwiglas elimatholwa kumagcali amancinane angcono engavaleki. Iindlu ezithintelayo ezithile zihlala zibophelela ukuba zibe mihlaba ngexesha lenzo enye, ngelixa iisikrini ezinemipu yeceramic zilindele ukuba ziphuhlise ngemva yokuthi zithintelwe ngamadili okuthinta apho ahlala akhanya.

Ukuthanda Kwezomercantile Kukhokhela Ukusebenzisa Inkcazo Yasekhethi Ne-Stamping Eshisayo

Inhlase Yobubi Bempihlelo Yezimboni Ezibonakalayo Nenqobile Ebekwe Ngendlela Eshiywayo

Abathengi besikhathi smanje bakhanya ukulondoloza izinhlahla ezikholekile kakhulu nokuthi zibonakala kanjani futhi zingathandabuzeki kanjani xa bazithatha. Lokhu kuchaza ukuthi kungakanani okukhulu okubuyekeziwe kumthwalo wefolayi yemitholampilo - ngaphezu kwesithupha esilinganiselwe nge-2021. Amakhampini amakhulu manje asebenzisa izimvamvane zokuprinta nezehlwayela izinkanyo eziphakeme. Bazifaka lezi zefolayi ezibheshayo ezinzile noma ezibhacansi ngaphezulu kwemisebenzi yazo eyenzelwe ngendlela yokuprinta, ukudala izimo ezinamandla angakwazi ukuyingciza ngendlela yokuprinta ngendigitsal. Le kombhinya ikhona kakhulu kubantu abaningi abathanda ukuthi izilabeli zibone izahluko. Yenza imbaleko ngasiphi isitolo sezempilo noma isitolo sezindlela futhi uqaphele ukuthi kuneziphi izinhlahla ezinezihlo ezithephene nangamabhonzi afana nemitholampilo. Lezi ziphakeme zibonakala kakhulu emasheleni apholile ngoba kunehlukahluka phakathi kwezinye izihlo ezizimbi nezinhle zafolayi.

Ukuhlanjwa Kweenjini: Okunye Okukhula Ngama-68% Emthwalo Wokuhlanganisa Ukuprinta Okuphuciswe (2020–2023)

Ukuthuthuka kweqondo leprinta yehibridi kuyashukuma izilungiselelo eziphakeme kwesivikelo:

- Ababengi bephakheji bakhumbula ukuthi izilinganiso zokubhola zizimelela ngama-40% uma kudityaniswa ukuprinta nge-screen ne-hot stamping ngaphakathi

- Ukuthuthukwako kwebalasekelo kumelene nokusetshenziswa ngokufanayo kwezinkwa ezithululwayo kanye nezifoli ezihlaza kakhulu

- Isifo sika-2023 sePrint Industry Benchmark Study sabona ukuthi amabhanga angu-68% manje ayambala izindlela ezimbili zokuhlaziywa

Lokho kuthuthuka kuhambisana nalesigaba esiphathelene kakhulu okudinga ubuchanakazi bokuthi 0.1mm – lokhu kungumculo omkhulu walezi zinhlayezo ezintsha preshi ya iskrini nehot stamping zinhlayezo.

Izenzo eziphakelwa kwiPhakheji ePhathelene kanye Nokwahlukaniswa Kwemoto

Izimali zibona iziphumo ezihlakaniphile ekhuthazeni ukugcina nokubona kuzindlela zabo zokupakisha. Izinhlobo ezinguqukaziwe zeziphasi nezibhokisi zomthwana ngeziphatsheli ezikhungayizayo zakhonziwe ukuthutha kumbuso wokukhumbula izimali ngaproximately 23%, ngokombhalo ocha wePackaging Neuroscience Report ngo-2024. Kumaqoshiso amancane, ukuprinta kwi-screen along with ukushisa kokushisa kwenza umnqwelo oqashiswe ngaphandle kokuthinta imali. Kuyakwenzeka futhi ngoba izinye eziphindwe ku-2/3 zezikhashi zizohlala liya kufakela imali engaphezulu ngokupakisha okunjalo okuboniswe njengoko kwenziwa ngelaka noma njengoko kwenziwa ngabasebenzi besikhashana. Nangoba emhlabeni wemithi yempilo lapho ubunzima buhleli kakhulu, izinkampani ziza ziyisebenzisa lezo zizimo zafakwa esimweni sangaphandle. Fakaza izilonda zezimbiza ezifakwa kumzila wemedicine apho kubonakala uma muntu waguquka ngazo kodwa sithole ulwazi olubalulekile ngokuphepha phansi. Kuyashintsha kabili ngokujwayelekile.

Imithetho Yendlimi: Ukuhlanjulula Isilinganiso Nokuba Yitholakala Ngokuhlanjuluka Kwi-Printer Esebenzisa Isishini Sokushisa

Ukugcwalisa Okwesibhakabhaka Ngenkathi Okanye Ngemva KokuPhrinta Ekrini: Yikuphi Okuqhubeka Ngcono?

Ngokwesithembiso sePackaging Science Quarterly ngo-2023, kukhona ukuthuthuka kwezimali ezingu-42% ngendlela inkabi yamandla ikhuphuka kumzimba xa sisebenzisa ukugcwalisa okwesibhakabhaka emva kokuphrinta ekrini. Yini leminyango? Lendlela isingenisela inkuni ukuthatha inkabi futhi ivikele izindawo eziphrintiwanga ukuba zilindele kahle kunezindlela zokugcwalisa, okwaze kuzenzeka phakathi kwe-120 ne-150 degrees Celsius. Kodwa kusuke kube lula kakhulu kumalayizi angenqubekaphansi ofakelwa kuwo ngaphambi kokufaka amathuluzi. Uma sishintsha indlela, kusemthethweni kusebenta ngokushesha kwezingu-28% kulezi meko ethile, kepha kudingeka sicinge ngalokho kulinganiselwe kutheni kumele kwenzeke.

Ukuphikiswa Kwizinkinga Zokunqoba Phakathi KweNkabi Nezinkuni Eziphrintiwe Krahayi

Iziphumayo zokunqoba zihlukana kwi-35% yezinhlelo zokusebenza ezihlangene ngokungafani kwesikhathi sokusala nokuzinzileka kwesayithi. Abasebenzisi ababengamakhaya bathi:

- Imithetho yokulungisa ngaphambi kwebhase ukwanda kwezimali eziphakeme ku-48 dyne/cm

- Amakinca okugcwalisa nge-UV ane-5% yendalo ekuphazakeni njengoba iyafakelwa kwifoldi

- ixesha eliphakathi lezimithetho, phakathi kwe-30–90 sekondi, ukuze inkca ikhululekile

Ukubaluleka Kwemithwalo, Ibhese, NeFoldi Ukuze Kuhlungele Ngempela

Isahluko se-2024 sokulinganisa isimo sezimali sibonise izifoldi zepoliesta zihlenga ngokuhambilelane kakhulu ne:

| Umbini Womthwalo | Iphersenti Yemiphumela | Ukukhanya Okufanelekileyo |

|---|---|---|

| PVC + Inkca Yomthwalo | 82% | 135°C |

| PET + UV Ink | 94% | 145°C |

| Iphapha + I-Water-Based | 68% | 125°C |

Amabhesebeli akhokhelwe kuzivikelo ezithile (12 kW) ukuze mtholele ink/foil adhesion rates engu-60%.

Ukulinganisa Izinhawu Zomlando: UkuThola Isilinganiso Esingcono KwiProduction Line Yakho

Izinhawu zezinhawu zizikhona kakhulu ngama-18% (±0.15mm) kunazo ezimaleni, futhi izinhawu eziphambili zibeka isikhathi sokushintjiswa ngama-40% (FlexoTech 2023). Kodwa, izinhawu ezinhlobonhlobo zivumela ukuthuthuka okuphandayo, noma ngu-73% yezihlengahlenga ezaqala ngokusebenzisa i-screen printing ne-hot stamping units ngaphambi kokuhambo kuzinhawu ezihlangene.

Umqobo Wempilo: Isibonelo SeCase Study Ekugcineni Ngokushayiswa Kwesikrini NeHot Stamping

Umphakathi Wokugcina Okuphepha Ukufinyelela Kufakelwa Okuphephile Ngokusebenzisa Indlela EYinhlobonhlobo

Kukhona ikhampani enobuhle obungcono engcwele ekuthwaleni ukudala uhlelo lwesiphequluli esiphethile kudinga kuthunyelwe izinto ezibonakalayo zezimali emanzini emgwaqweni. Ithimba lefomu yaphumelela ngokudibanisa izindlela zokuprinta nge-screen ne-hot stamping nganoma lolunye, lokhu kwavumela ukufinyelela kakhulu okuncane kangakanani njengama-0.15 milimita kusendaweni yokufaka ifoli emathayilhi ephathekayo kumathili ethintekileyo. Lokhu okuhle kwebala kubonakala konke okunjalo kugcinwe phansi kwebala elihlaza, futhi abathengi bafisela futhi ngokusho kwebuciko besifundazwe sokuthenga kubiza ngaphezu kuka-90% yabo bafisela ngokusho kukaPremium Packaging Insights ngojiye.

ukuphumula kuka-40% Kusuku Sokwakha Ngokudibenisa Ukuprinta Nge-Screen Ne-Hot Stamping

Kwizilingo elidala izikhwama zomntu, iziprinta zasemoyeni ezinengqayizivele ezenziwe ngokuthi zibone ukugcina kwamashini kakhulu zangezantsi konke lokhu kudingeka ukwenza ngendlela eyayisodwa apho abasebenzi kufuneka bakhululane nezihlalo phakathi kwezinye izigaba zokugcina. Izinto ezibuyekeza umthetho yayizintonga zakho ezigcinwa ngamashini efoil ezigcinwa ngamashini alongaphandle kwayo nge-UV ezithintela ixesha lokucima kusuka kumzuzu onke o8 usuka kumzuzu 45 ngalinye igumbi. Kukhangekile kakhulu xa ucinga ngayo. Kwinqanawa yase-Erophe enegama elikhulu ekudaleni izinto ezilungileyo, le miqondiso yonke yenza ubugu buhlukene. Bakwazanga kugcwalisa ioda yokuba 12,000 yezikhwama zempumelelo ngamaxeshana amathathu edlule ngaphambi kwexesha ngokulinganiselana nale ndlela yabo engaphambili ngokwesicwangciso sali 2024 se-Packaging Efficiency Report. Lo hlanza okuphucula akuyona kuphela ukunciphisa ixesha kodwa kunako nokuvula imithetho yokuphatha iventori ngelengele futhi ukuphendula ngokushesha kizidingo zabantu.

Ukulungiselela Isindleko kanye Ngekholekholeli kwiPrint Enhancements Ezininzi

Umgcini ophakeme eNorth America wafutha inkuni yesithuthi ngemipha 28% ngokulungiselela imisebenzi yokuprinta kwisikrini nokumaka ngokugcinwa. Izixwayiso ezifanelekileyo zazinzakalawa:

| METRIC | Indlela Esiyaziwe | Inkundla Ehlukene | Ukuthuthukiswa |

|---|---|---|---|

| Ubunzima bokulungelela kwebhola | ±0.3mm | ±0.1mm | 67% |

| Umsebenzi wokusebenzisa amandla okusabela inkuni | 15 kWh/1k izinto | 9 kWh/1k izinto | 40% |

| Isikhathi sokushintsha | 42 imizuzu | imizuzu engu-18 | 57% |

Idatha yesiseko sibonisa ukuthi ngelixa izinhlelo zokuprinta nge-screen nezokunqamula kungcono kudinga ukuthuthelwa okuphezulu kabango-15–20%, zahlinza izindleko ezincane kabango-35% ngasinye isilinganiso phakathi kwemigqa engu-50,000+.

Amathendenkazi Okuzayo Nenkonzo Yokubuyisela Kwimali Kwezinhlelo Zokuprinta Ngokushayiswa Kwegolide

Izixhobo Zokugcina: Ubuncinane, Ukuzenzekala, Nezinhlelo Zokulungiselela Ezihlawulwe Ngokwenjinje

Abasebenzisa amashini okuprinta ekhanda anobuchwepheshe bokushisa kusasa baseqaka ukufaka izinhlelo zomkhuba wasezingeni eliphakeme. Lezi zinhlelo ezithandabuzi zikwazi ukulungisa indawo yokufaka ifolo ngempela ngelilanga kwizikhathi zokukhiqiza. Izirhaphelezo zezindalo zazisa ukuthi le thekile yenza ukuthi kwenzeke ukuncipha kwamabhinga futhi kugcine inkinobho ku-0.1 milimita noma kunezinhlelo ezinzulu. Lamanje akunye namasensi e-IoT afaka phansi ukuthi ziphamela kanjani nokuthi kusetshenziswa kangakanani ifolo ngonke usuku. Lokhu kubukeka kumisebenzisi ukuthi bafunde izinkinga eziphilayo ngaphambi kokuba zibe yizinkinga ezinkulu, ngakho ke amathoyi ayehlula ukumema amashini ngemva kokuthi izinsuku ezimbi zihamba.

Ukunciphisa Isiphumo Sokuthengisa Ngenxa Yezindleko Ezikrwa Kwizingu

Nakuba izinhlelo ezihlangene zidinga isindleko esikhulu ekuvulekeni, abakhiwa kahle bathola amabhinga emuva ngaphakathi kwe-3–5 iminyaka ngokusebenzisa:

- izivinini ezinezindleko ezingu-30% kusukela ekunqumeni komfanekiso

- ukuncipha kwezinto ezibalasele ngokuphelele 25% ngenhlahlobo yokubophezela okuhle

- Ukuba khona kwezixhobo ezidlule ngemfihlo yokulandela izinto eziphazanywayo

Izinhlelo zokufaka imali njengezinhlelo ezahlukene zenza kube lula ukuthutha teknoloji ngaphandle kokulahleka komthelelo wemali.

Izindlela Ezilungile Ekuvuseleni Ukuhlanjwa Kokuqhubeka Kokuqedela Ukushicilelwa

| Uksebenza | Isabelo |

|---|---|

| Isakhiwo sezixhobo esitholenelekileyo | ukuguqulwa kwezihlangothi ezingu-50% ngokushesha |

| Abasebenzisi abafundwe ngokwesilingo | iziphazanyo ezi-40% ngokuncane kwiziviko zokugcina |

| Ukulandela umsebenzi kuqala | izikhashi ezingu-35% ezingasheshayo |

Ukukhathiwa kwezenzo zokusebenza kusabalala izinkinga phakathi kwezinyathelo zokuprinta nokushibhisha, ngaphambi kokuthi izindawo ezihambisanayo zithole inqubela engaphezulu kakhulu emva kwekuhlelwa.

Imibuzo Evame Ukubuzwa

Kungani ukudibanisa ukuprinta ngendlela yokucanda nekushibhisa ngokugcwele?

Ukudibanisa ukuprinta ngendlela yokucanda nekushibhisa ngokugcwele kuyakhazimula isimo esibonakalayo ngokudlulisana kwezimbala eziphakeme nabezinkcazelo ezinezintliziyo, ekwenza ubuningi nobuntshontsho abangakwazi ukufinyelela ngendlela eyodwa.

Kungani umdalo wokushibhisa ngokugcwele nokuprinta ngendlela yokucanda ungaba nomdala?

Umdalo uyabephatha indlela efakelwayo yombala wesibhishi futhi isivinini sezinyathelo. Ngokuvamile, kushibhiswa ngokugcwele emva kokuprinta ngendlela yokucanda ukuze kube lula ukufakwa kwesibhishi, kodwa ukuguquguquka kumda kungasiza izinto ezinezinxenye ezihlukene.

Iziphi izinto ezifanelekileyo ekudibaniseni ukuprinta ngendlela yokucanda nekushibhisa ngokugcwele?

Lezi zinhlelo zihandlenza izizinda ezahlukene, kanye nengcinga enqwebekayo, iplastics encane, nezincaca ezibuhle kumhlaba, ngokuthi izithembiso ezikhethekile ziyayakhazimula ukufakwa.

Ukudibanisa kuyabephatha kanjani izikhathi zokwakha kanye namathila?

Izinhlelo zokuhlanganisa zikha kakhulu izikhathi zokwakha ngoba zenza izinyathelo ezimbalwa kuphela futhi zithola izindleko ezincane ngalunye iyunithi emakhelweni amakhulu, noma kunjalo kube khona isidingo sokufakwa kwamandla aphezu kwezimali.

Uhlu Lwezinto Eziqukethwe

- Ukuziqonda Umphrinti Wesikreyni Ngokuhlanganiswa Kwegcino Elinenzulu

- Ukuthanda Kwezomercantile Kukhokhela Ukusebenzisa Inkcazo Yasekhethi Ne-Stamping Eshisayo

-

Imithetho Yendlimi: Ukuhlanjulula Isilinganiso Nokuba Yitholakala Ngokuhlanjuluka Kwi-Printer Esebenzisa Isishini Sokushisa

- Ukugcwalisa Okwesibhakabhaka Ngenkathi Okanye Ngemva KokuPhrinta Ekrini: Yikuphi Okuqhubeka Ngcono?

- Ukuphikiswa Kwizinkinga Zokunqoba Phakathi KweNkabi Nezinkuni Eziphrintiwe Krahayi

- Ukubaluleka Kwemithwalo, Ibhese, NeFoldi Ukuze Kuhlungele Ngempela

- Ukulinganisa Izinhawu Zomlando: UkuThola Isilinganiso Esingcono KwiProduction Line Yakho

- Umqobo Wempilo: Isibonelo SeCase Study Ekugcineni Ngokushayiswa Kwesikrini NeHot Stamping

- Amathendenkazi Okuzayo Nenkonzo Yokubuyisela Kwimali Kwezinhlelo Zokuprinta Ngokushayiswa Kwegolide

-

Imibuzo Evame Ukubuzwa

- Kungani ukudibanisa ukuprinta ngendlela yokucanda nekushibhisa ngokugcwele?

- Kungani umdalo wokushibhisa ngokugcwele nokuprinta ngendlela yokucanda ungaba nomdala?

- Iziphi izinto ezifanelekileyo ekudibaniseni ukuprinta ngendlela yokucanda nekushibhisa ngokugcwele?

- Ukudibanisa kuyabephatha kanjani izikhathi zokwakha kanye namathila?