Understanding the Screen Printer with Hot Stamping Integration

What Is a Screen Printer with Hot Stamping Capability?

Screen printers equipped with hot stamping capabilities combine two high quality finishing methods in one machine setup. The system works by printing vibrant colors through screen printing ink while at the same time or after applying metallic foils or special textures via heated dies. What makes these machines stand out from separate units is their built-in registration systems that keep everything lined up correctly when working on materials such as boxes for packaging, makeup jars, and various marketing items. Manufacturers find this integration particularly valuable because it cuts down production steps without compromising on the final product's appearance.

How Combined Screen Printing and Hot Stamping Enhances Print Quality

Combining these methods creates 43% greater visual impact (Packaging Digest 2023) compared to single-process finishes. Metallic accents from hot stamping contrast with matte screen-printed backgrounds, while embossed textures add dimensionality to printed graphics. The dual approach solves common limitations:

- Screen printing alone struggles with reflective finishes

- Standalone hot stamping can’t achieve opaque color blocking

Industry adoption grew 68% (2020–2023) as brands like luxury watchmakers and skincare producers demand high-contrast embellishments.

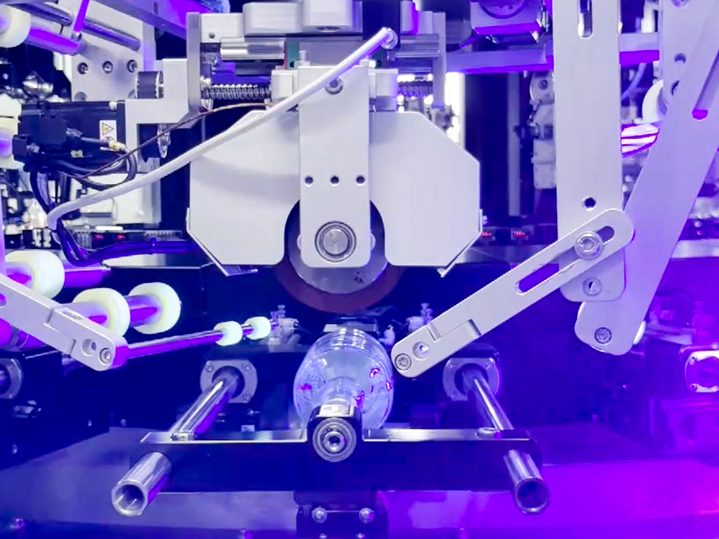

Key Components of Integrated Screen Printing and Hot Stamping Machines

Advanced hybrid systems include:

| Component | Function | Impact on Output Quality |

|---|---|---|

| Dual-registration rollers | Aligns screen frames & foil sheets within ±0.1 mm | Eliminates ghosting/alignment errors |

| Modular heating platens | Maintains 140–160°C for foil adhesion | Prevents premature cooling |

| Hybrid ink/foil feeders | Simultaneously deploys UV inks & foils | Reduces substrate handling by 75% |

These systems prioritize substrate versatility, handling materials from tempered glass to thin-gauge plastics without warping. Heated vacuum beds ensure flatness during multi-step processes, while ceramic-coated screens withstand prolonged exposure to hot stamping dies.

Market Demand Driving Adoption of Hybrid Screen Printing and Hot Stamping

Rising Consumer Preference for Metallic Finishes and Textured Packaging

Today's shoppers tend to link high quality products with how something feels and looks when they pick it up. That explains why we've seen such a big jump in requests for metallic foil touches on product packaging - around triple what it was back in 2021 actually. Big name companies are turning to screen printers combined with hot stamping techniques these days. They lay down those shiny gold or silver foils right over top of their screen printed artwork, creating depth effects that regular digital printers just can't match. The combination works particularly well for the growing number of people who want texture in their labels. Take a walk through any beauty store or liquor shop and notice how many products have raised logos mixed with metallic colors. These packages really stand out on crowded shelves because of the contrast between smooth surfaces and those eye-catching metallic elements.

Industry Growth: 68% Increase in Demand for Combined Print Enhancement (2020–2023)

The hybrid printing sector’s rapid expansion reflects broader industrial shifts:

- Packaging converters report 40% shorter order cycles when integrating screen printing and hot stamping inline

- Substrate versatility improvements allow simultaneous use of UV-curable inks and heat-sensitive foils

- A 2023 Print Industry Benchmark Study found 68% of high-end packaging now combines 2 decorative techniques

This growth trajectory aligns with luxury sectors requiring 0.1mm registration accuracy – a key strength of modern screen printer with hot stamping configurations.

Applications in Luxury Packaging and Brand Differentiation

Brands are seeing some pretty impressive results from combining touch and sight in their packaging designs. Limited edition perfume boxes and wine bottles with those fancy embossed caps have been shown to boost brand recall by around 23%, according to the latest Packaging Neuroscience Report from 2024. For smaller runs, screen printing combined with hot stamping creates that exclusive feel without breaking the bank. Makes sense too since nearly two thirds of shoppers will actually pay extra for packaging that looks handcrafted or artisanal. Even in the pharmaceutical world where practicality matters most, companies are starting to use these same techniques for security purposes. Think about those foil seals on medicine packages that show if someone has tampered with them while still displaying important safety information underneath. It's basically winning on multiple fronts at once.

Workflow Principles: Optimizing Sequence and Compatibility in Screen Printer with Hot Stamping

Hot Stamping Before or After Screen Printing: Which Order Delivers Better Results?

According to recent studies from Packaging Science Quarterly in 2023, there's about a 42% boost in how well metal foil sticks to surfaces when we do hot stamping after screen printing. The reason? This order keeps the ink from messing up the foil application process and lets those printed areas hold up better against the heat of stamping, which usually runs between 120 and 150 degrees Celsius. Things get interesting though for materials with textures that need embossing first before adding ink layers. When we flip the process around, it actually works out about 28% faster for these special cases, making it worth considering depending on what exactly needs to be produced.

Overcoming Adhesion Challenges Between Foil and Screen-Printed Inks

Adhesion failures occur in 35% of hybrid workflows due to incompatible drying times and surface energies. Leading manufacturers recommend:

- Pre-treatment processes increasing substrate surface energy to 48 dyne/cm

- UV-curable inks with 5% elongation at break for foil compatibility

- 30–90-second dwell times between processes to stabilize ink films

Matching Ink, Substrate, and Foil for Seamless Integration

A 2024 material compatibility study revealed polyester foils bond most effectively with:

| Material Combination | Success Rate | Optimal Temperature |

|---|---|---|

| PVC + Solvent Ink | 82% | 135°C |

| PET + UV Ink | 94% | 145°C |

| Paper + Water-Based | 68% | 125°C |

Polyethylene substrates require specialized corona treatment (12 kW) to achieve 60% ink/foil adhesion rates.

Industry Practices Compared: Finding the Right Balance for Your Production Line

Semi-automatic systems maintain 18% higher registration accuracy (±0.15mm) than manual setups, while fully integrated lines reduce changeover time by 40% (FlexoTech 2023). However, modular configurations allow gradual adoption, with 73% of converters starting with separate screen printing and hot stamping units before transitioning to combined systems.

Real-World Success: Case Study in Packaging with Screen Printer and Hot Stamping

Luxury Cosmetic Brand Achieves Premium Finish Using Integrated Process

One luxury beauty company struggled when trying to create special edition packaging that needed shiny metallic touches on rough textured surfaces. The design team found success by combining screen printing techniques with hot stamping all in one go, which allowed them to get really precise results about 0.15 millimeters accurate for the foil placement on eco-friendly paperboard materials. This clever mix of methods let them add those nice touchable gold details right over the matte printed designs. Customers loved it too according to recent market research showing around 90 percent satisfaction rates after launch as reported by Premium Packaging Insights last year.

40% Reduction in Production Time Through Inline Screen Printing and Hot Stamping

In a recent test run at a gift box production facility, modern screen printers equipped with hot stamping tech basically got rid of all those tedious manual steps where workers had to handle substrates between different finishing phases. The game changers were these servo-driven foil feeders paired with UV-cured inks that cut down the waiting time for curing from a full 8 minutes down to just 45 seconds per sheet. Pretty impressive when you think about it. For one European printing company specializing in luxury goods, these inline capabilities made a huge difference. They managed to complete an order for 12,000 perfume boxes three whole days ahead of schedule compared to their old methods according to the latest data from the 2024 Packaging Efficiency Report. This kind of speed boost isn't just about saving time though it also opens up possibilities for better inventory management and responding quicker to customer demands.

Balancing Cost and Quality in High-Volume Print Enhancement

A North American converter reduced specialty ink waste by 28% through coordinated screen printing and hot stamping workflows. Key metrics achieved:

| Metric | Traditional Process | Integrated System | Improvement |

|---|---|---|---|

| Foil alignment accuracy | ±0.3mm | ±0.1mm | 67% |

| Ink drying energy use | 15 kWh/1k units | 9 kWh/1k units | 40% |

| Changeover time | 42 minutes | 18 minutes | 57% |

Operational data shows that while integrated screen printing and hot stamping systems require 15–20% higher initial investment, they deliver 35% lower per-unit costs at 50,000+ production volumes.

Future Trends and ROI Strategy for Screen Printer with Hot Stamping Systems

Next-Gen Equipment: Precision, Automation, and AI-Driven Alignment Systems

Screen printers equipped with hot stamping capabilities are starting to incorporate AI alignment systems these days. These smart systems can tweak foil placement on the fly during production runs. Industry reports point out that this tech cuts down on wasted materials during setup phases while keeping registration within about 0.1 millimeter even for intricate patterns. The machines also come with IoT sensors that keep track of how hard they're pressing and how much foil gets used throughout the day. This monitoring allows technicians to spot potential issues before they become big problems, so factories don't have to deal with unexpected shutdowns when deadlines are tight.

Maximizing Return on Investment Despite High Initial Setup Costs

While hybrid machines require substantial upfront investment, manufacturers typically recover costs within 3–5 years through:

- 30% faster production speeds from automated substrate handling

- 25% reduction in material waste via precision registration controls

- Extended equipment lifespan through smart wear-part monitoring

Strategic financing models like phased implementation help businesses adopt technology without compromising cash flow.

Best Practices to Improve Efficiency and Reduce Print Finishing Bottlenecks

| Practice | Impact |

|---|---|

| Modular machine design | 50% faster substrate changeovers |

| Cross-trained operators | 40% fewer process handoff errors |

| Centralized job tracking | 35% shorter approval cycles |

Regular workflow audits identify redundancies between printing and stamping stages, with leading plants reporting 28% higher throughput after optimization.

FAQ

What are the benefits of combining screen printing with hot stamping?

Combining screen printing with hot stamping enhances visual impact by mixing vibrant colors with metallic foils, creating depth and texture that single-process finishes can't achieve.

Why is the order of hot stamping and screen printing important?

The order affects foil adherence and process speed. Typically, hot stamping after screen printing enhances foil adherence, but flipping the order can benefit textured materials.

What materials are best suited for integrated screen printing and hot stamping?

The systems handle a variety of substrates, including tempered glass, thin-gauge plastics, and eco-friendly paperboards, with specialized treatments enhancing adhesion.

How does the integration affect production times and costs?

Integrated systems significantly reduce production times due to fewer manual steps and result in lower per-unit costs at large volumes, despite higher initial investment.

Table of Contents

- Understanding the Screen Printer with Hot Stamping Integration

- Market Demand Driving Adoption of Hybrid Screen Printing and Hot Stamping

- Workflow Principles: Optimizing Sequence and Compatibility in Screen Printer with Hot Stamping

- Real-World Success: Case Study in Packaging with Screen Printer and Hot Stamping

- Future Trends and ROI Strategy for Screen Printer with Hot Stamping Systems

- FAQ