The Challenge of Small Print Runs in Traditional Workflows

Why Small Print Runs Strain Conventional Analog and Digital Production Systems

The old school printing processes just don't work so well for small print runs because setting everything up takes forever and there's lots of hands on work involved. With traditional analog methods, printers have to swap out actual plates and double check alignments, which eats up time. Even the digital options aren't much better since they still need all sorts of prep work before anything gets printed. When dealing with orders below around 500 pieces, these delays start costing way too much money. That's why quite a few print shops either turn down these little jobs altogether or slap on extra charges that make customers think twice about placing them in the first place.

High Setup Costs and Downtime Reduce Profitability for Low-Volume Jobs

Changing jobs on traditional printing presses eats up anywhere from 22 to almost 40 minutes each time there's no actual work getting done. That becomes a real problem when dealing with lots of little orders throughout the day. The setup costs alone eat up about a third of what it costs to produce anything under 1,000 units. Without some kind of minimum order size, most companies just can't make money on these smaller print jobs. Industry folks keep saying things like "brands need short run, customized printing if they want to get their money's worth out of print spending" but the old school equipment simply isn't built to handle this stuff without losing money hand over fist.

Labor Intensity and Material Waste in Non-Digital Printing Processes

Both offset and screen printing require experienced hands to match colors and adjust presses, which really adds up to labor expenses especially when production runs are short. Traditional printing techniques actually produce around 18 to 25 percent more waste material compared to digital options during those initial setup phases and calibration periods. This kind of waste just doesn't cut it anymore when companies need every last bit of material to count toward their bottom line. That's exactly why we're seeing more shops switch to single pass UV inkjet printers these days. They handle quick turnaround jobs much better and allow manufacturers to stay competitive without sacrificing quality or going through excessive amounts of wasted materials.

How Single Pass UV Inkjet Printer Technology Solves Short-Run Challenges

Instant Job Switching With No Mechanical Reconfiguration Required

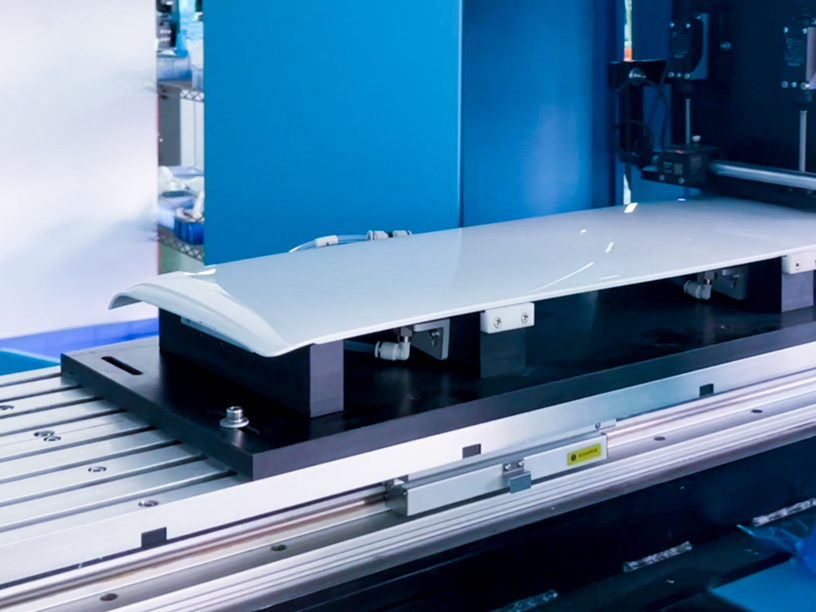

UV inkjet printers in single pass configuration cut out those lengthy setup changes that plague traditional printing workflows. Screen printing and offset techniques require all sorts of physical adjustments to templates, but digital systems just switch between different print jobs without any fuss. The operator loads fresh design files into the system while keeping everything else running smoothly since the UV lamps stay put and printheads don't need repositioning. According to research from Piriz back in 2023, this approach slashes changeover time by around three quarters when compared with older methods. What does this mean practically? Small batch sizes suddenly become economically feasible too. A shop can run off just ten units at a time instead of needing to commit to thousands for cost efficiency.

One-Pass UV Printer Speed Enables 70% Faster Output vs. Multi-Pass Systems

By curing ink instantly during the printhead’s single traversal, these printers achieve speeds exceeding 300 feet per minute—70% faster than multi-pass alternatives according to Smithers’ 2024 digital production analysis. This velocity stems from two innovations:

- Parallel printing – All color channels apply simultaneously rather than sequentially

- Continuous motion – Substrates move uninterrupted beneath static, high-density printheads

The efficiency lets manufacturers complete 12+ short-run jobs per shift that previously required 2—3 days.

Reduced Ink Usage, Energy Consumption, and Labor Per Job

The single pass system actually uses around 40 percent less ink compared to older analog approaches because it controls each drop so precisely. And when it comes to curing, those UV LED lights take only about 65% of the energy needed by those big old drying tunnels most shops still rely on. What really makes a difference though is automation. With automated setups, one person working the floor can handle five times as many print jobs every hour compared to what was possible with manual presses back in the day. This kind of efficiency means businesses can actually turn a profit even on small orders below five hundred bucks. Something that used to be a money pit for short runs now becomes something that brings cash into the door instead.

Scaling Small-Order Production with Automation and Efficiency

Case study: Custom packaging company triples small-order throughput

One packaging converter based in the Midwest saw an amazing 320 percent improvement in how fast they turn around jobs after switching to single pass UV inkjet printers combined with automated workflows. The setup cut down on those tedious manual plate changes by almost 92%, which is huge when trying to keep colors consistent at 99.6% accuracy even for small batches. This kind of precision makes all the difference for those last minute orders coming in from smaller cosmetic companies that need things done quickly. What used to be about 15 jobs per day has jumped to 47 now, with each run typically hitting around 250 units. That's quite a leap forward for their business operations.

Automated RIP and job queue management for seamless high-mix production

The latest generation of UV inkjet systems handles complicated variable data tasks with about 38 percent fewer steps than what we saw in machines from 2020. These systems come equipped with real time RIP engines that tweak nesting layouts on their own while still checking each droplet for quality. What does this mean for operators? They can actually stack up over a dozen different design files in the queue and walk away for the night without needing to babysit the process. The automation has really cut down those frustrating wait times between print jobs too, going from roughly 22 minutes of downtime down to just under a minute and a half now.

Maximizing uptime: Overcoming the underutilization of high-speed printers

Single pass UV printers in sample kit production facilities achieve 86% uptime through automated nozzle recovery systems that perform 4,000+ maintenance cycles between technician interventions. This contrasts with multi-pass systems requiring manual cleaning every 2.5 operational hours–a workflow mismatch that wastes 31% of potential capacity on small batches under 500 units.

Driving Profitability in Custom and Personalized Printing Applications

Capturing Niche Markets with Personalized Labels, Decor, and Variable Data

The custom printing sector is really taking off these days, accounting for about 28% of all commercial print revenue growth according to Market Data Forecast from 2024. People want their stuff personalized these days whether it's packaging for products, decorations for events or marketing materials that speak directly to them. Thanks to variable data printing technology, companies can create customized items on a large scale. Take those single pass UV inkjet printers for instance they can handle over 10,000 different designs in one go without stopping production, which makes small batch runs actually worth the investment financially. Research published by the European Federation of Print and Digital Communication back in 2022 found something interesting too personalized print campaigns tend to get around 30% better responses from customers than regular mass produced ones do.

Full-Color Customization Flexibility Using Single Pass UV Inkjet Printer Systems

Modern UV inkjet technology supports 98% of Pantone colors in a single pass while maintaining 1,200 dpi resolution–critical for luxury branding applications requiring metallic accents or textured finishes. This eliminates traditional CMYK process limitations, allowing B2B printers to fulfill complex customization requests in –24-hour turnaround times.

ROI Advantages for Early Adopters in B2B Custom Print Segments

Businesses that have started using scalable personalization tech are seeing some impressive results. Their gross margins on small batch orders jump about 42% higher than what traditional offset printing methods can deliver. Looking ahead, the market for personalized printing software is expected to grow substantially, hitting around $2.2 billion by 2026 according to recent industry reports. For companies getting serious about UV inkjet automation right now, there's real potential to command better prices in niche areas where customization matters most. Think about things like specialized labels for medical devices or those special edition product packages that stand out on store shelves.

Single-Pass vs. Multi-Pass UV Printers: Best Fit for Small-Batch Production

Speed, Resolution, and Operational Maintenance Comparison

The single pass UV inkjet printer does all its work in one go across the material, which means it runs about 70 percent quicker than those multi pass alternatives according to Smithers research from last year. Multi pass models build up layers of ink over multiple trips across the page to get that really sharp image quality sometimes going beyond 1200 dots per inch. But there's a trade off here since these machines tend to have more moving parts and complicated mechanics inside. What makes single pass systems stand out is how they cut down on alignment problems and time spent fixing things because they don't need those repetitive back and forth movements. For smaller print jobs where getting stuff done fast matters more than pixel perfect details, these printers make a lot of sense in practice.

| Factor | Single-Pass UV Printers | Multi-Pass UV Printers |

|---|---|---|

| Speed | 300+ sheets/hour | 90–120 sheets/hour |

| Resolution | 600–1,000 dpi | 1,200–2,400 dpi |

| Maintenance | 2–4 hours/week | 6–8 hours/week |

Total Cost of Ownership: Why Single-Pass Wins for Short Runs

The operational economics of single-pass UV inkjet printers favor small batches through:

- 55% lower energy use per job (no repeated substrate handling)

- 30% less ink waste from minimized setup and calibration

- Labor costs reduced by 40% compared to multi-pass workflows

For runs under 500 units, single-pass systems achieve 18–22% lower cost-per-print by eliminating pass-to-pass alignment labor and material overruns.

When Multi-Pass Systems Still Make Sense–and When They Don’t

Multi-pass UV printers remain viable for:

- Specialty applications requiring metallic/3D effects

- Ultra-high-resolution pharmaceutical packaging (¥1,500 dpi)

- Static print designs with unlimited run lengths

However, 83% of under-1,000-unit jobs analyzed in 2023 showed stronger ROI with single-pass technology–particularly for personalized products needing rapid job turnover.

FAQ

What are the challenges of small print runs in traditional workflows?

Small print runs in traditional analog and digital systems face high setup costs, labor intensity, and material waste, making such operations unprofitable.

How do single pass UV inkjet printers solve short-run challenges?

They allow instant job switching without mechanical reconfiguration, enabling faster output, reducing ink use and energy consumption, and improving profitability.

What is the advantage of single pass systems in small-batch production?

The systems cut down on maintenance and alignment problems leading to higher uptime, lower costs, and improved efficiency for short runs.

Table of Contents

- The Challenge of Small Print Runs in Traditional Workflows

- How Single Pass UV Inkjet Printer Technology Solves Short-Run Challenges

- Scaling Small-Order Production with Automation and Efficiency

- Driving Profitability in Custom and Personalized Printing Applications

- Single-Pass vs. Multi-Pass UV Printers: Best Fit for Small-Batch Production

- FAQ