Ukuthinte Kwezinsawo Ezingaphansi Esikhundleni Sokuphrinta Kwemali Inkjet

Izinkotha zokuprinta inkjet zilandelayo zinezinkinga ngokwenza izinsawo ezingaphansi nezinto ezinezwelelweyo kanti izinkinobho zazo zikhale kuzindawo eziyinkimbinkimbi futhi indlela abo zayithumela inkjet ikusebenza ngakunye kuzinsawo ezithile. Xa kuphrintwa kuzinto ezibhujwe njengamabotile okunywa noma izinhlobo ezindlela zokwenza kwezinhlobo zokwenza kwezimali nezithuthi zokuthi zinezinga elithile, lezi zinkinga zenza izinkinga ngokuthi inkjet iyiphi ekuhlelweni. Iziphumo? Ikhwalithi yokuprinta iyaphansi kakhulu. Izindlela zokwenza izibonelo ukubonisa ama-defects kancane 12-18% ngokuprinta kuzinsawo ezingaphansi kunokuprinta kuzinsawo eziyinkimbinkimbi. Lokhu kusebenza ngokwengeziwe kakhulu kwezindlela zokusebenza zilandelayo xa kubhekwa kuzindlela ezahlukene.

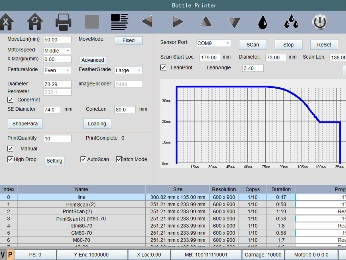

Ukuthwasa Imiphumela Yezindlela Zokuprinta Inkjet Zilandelayo Kuzinsawo Ezibhujwe nezinsawo eziyinkimbinkimbi

Izinto ezintathu eziphambene nezinye zenza lezi zinkinga zibe ngokungcono:

- Ukuthenteka kwezindlela zokuthumela inkjet : Izindlovu ziyethumela inkjet 0.5–3 mm ngaphambili kuzinsawo ezibhujwe kunokuzinsawo ezibhujwe ngapha

- Ukungcola kwezinyukelo zokwenza : Izinguquko zokusebenza kwezinyukelo ezincane kunoma 5 dynes/cm zihlinza ukushunywa kwamanqina

- Imigomo egqithileyo yokushusha : Izinto ezingenakuphumelelwa zenza imiclimbi yemikrumele apho izigaba zokushusha ziguqula ngama-40%

Isicwangciso esithile soku-2024 sabonisa ukuba iziguquko ezincane kunoma 30 cP nezikhankanyo ezingaphansi koma-50 µm zenza ukungcola kwezinto, ukushintshela inani le-Ohnesorge (isigama soku- Z) ngaphandle kwekota ephambeneyo 1–10 ye-ukwenza kwezinyukelo ezingenakuphumelelwa.

Izinto eziphambeneyo ezingaphambeneyo nokuba kwezinyukelo zokuprinta kwiindlela ezingenakuphumelelwa

| Ukuhlanganiswa | Ukuvumelana nokuphumelelwa kwesigaba | Ukuvumelana nokuphumelelwa okungenakuphumelelwa |

|---|---|---|

| Ubukhulu benqina | ±2% yokuqinisekileyo | ±0.5% kudingeka |

| Umvalelo weprinta | 1–2 mm kuvumelekile | 0.3–0.7 mm okuningi |

| Ukukhanya kwe-Substrate | 0–5° kusebenza | >15° kuthutha kakhulu kweqothe lekwe 70% |

Izprinta zokulayisha inkhando zokwenza lezi zimanyano ngokuthi zisebenzisa izindlela ezingenakukhohlwa (do 25 mm ngaphandle kwezinye ezi 5–8 mm) futhu ukulungisa okusheshayo kwe-velocity yedropile.

Ukukhawuka kwe-Substrate kuzo Ziziphumo ze-Inkjet Printing: Ukuhlala, Isayizi, futhu I-Geometry

Xa umoya wesayizi uphansi kwe-38 mN/m, oku kungenzeka kakhulu kwi-plastics neemeko yemetalu, kuya kudinga ukuthi usebenzise amandla okuqinisa inkhukhwanyiswa yokupakisha. Kuzo zinto eziphambene nazo zonke apho ubukhulu bokwenyaniwa bungenye kwe-6.3 micrometers Ra, ikhwalithi yemoto yezinkawuntiselo zokuprinta zokuthi inqanawe ukusebenza kune-98% ngokukhuthaza ukwenza amandla wokuvimba. Iziphumo ezijwayelekileyo zokuprinta ziyasebenza phakathi kwe-82 kunye ne-88% kuphela kule ndawo. Okuqukethweyo kule ngxelo yokuqala ngokuqinileyo nguqulelo yokuprinta engenazo ukuthintana. Le ngxelo ezintsha iyakha amaprinta akhoyo kwaye enyekele kakhulu kwaye iyasebenza ngaphandle kwekho ukuthintana ngokuphawuza kwe-120 amadigri.

Iingxelo Ezibalulekileyo kwi-Tech yemoto ye-Inkjet Printer enye kwezindleko ezikhulu

Ukugcinwa kwezindleko kwaye ukwenyeliswa kwezindleko kwiingcinga eziphambene

I-generation e-ncane ye-inkjet printers ikhuluma ngokusetshenziswa kwezinkwelelo zokwenza ink droplets ezilandela kahle xa kudlalwa. Imicabango yekhweyintsha kugcwalwe ngo-2023 iyavuma ngendlela lezi zinhlelo zokudlala ezinhlelo zokudlala kuzindawo zokudlala, futhi okutholwe kungukuthi kuyavuma kakhulu. I-print heads ezinokuthi zilayishwe kahle kancane ngaphansi kwe-20 microns kudinga ukuthi zilandele kahle ngokuphelele 98 kwe-100 xa kudlalwa kulezi zinto ezihlanzekileyo ezithathwe kuzindawo zokudlala ezithathwe kuzindawo zokudlala. Okuqondile kule teknoloji kukhona ukuthi kungenzeka ukusebenzela kuzinye izincazelo ezingenakho kahle. I-printers ivela nezikwele zokuscana nge-laser ezinokuthola ubukhulu obuvamile kwe-15 millimeters esibonakalweni. Lokhu kusho ukuthi nokuthi kunezinkinga eziphansi noma ziphansi kuzinto ezidliwayo, le nhlelo iyasebenza kahle kulo moya, iyasebenza kahle kuzinye izincazelo ezithambisa kakhulu ngokuvarying ngama-3 amadigri kusuka kuzilimo ezilandelene.

Umrhwebho phakathi kwe printhead kunye nekapasiti yo uthayipha inkhweleti kwiistim kweqhubu elikhulu

Iiproda eziphume kwi-600–1,200 dpi ngezithuba zokuthayipha kwi-8–25 mm—40% ngapandle kwezifazwe ezidala. Oku kuvumela ukuprinta kwiipaki eziphantsi noma kwiindawo ezinemveliso ngaphandle kokulahla ukuba ngokusheshayo. Iinkhweleti zokuprinta eziphathelene nezulu zixhobiswe ngoku kuba neviscosity echanekileyo (<5% ishishino) kuzithuba zokuphuma kwi-8–15 mm, zikwamkela izisukululo ngapandle kwe-120 m/min.

Isakhiwo senozzle kunye nezinkxubu zokwenza inkhweleti iyaphepha ngokulinganayo

Iinozzle evelwe ngokwenziwa kwe MEMS (40–70 µm diameters) ziyaphepha ukulinganayo ngokwenyani ngokwenza:

- Imifutyo ye-hydrophobic eyamkela ukulahla kwekhweleti nge-22% kwi-plastics engenazo amandla

- Iingxenye eziguquliweyo ezixhomeke kwi-±1.5% imbangela yekhweleti ngokulinganayo kwi-30 kHz izisukululo

Ukuthuthwa kwiintambo zokuprinta eziphezulu zibonisa indlela abasebenzisa izakhiwo ezininzi zokwenza inkhweleti i-0.1 µL ± 0.005 µL—okuyinxenye encinciyo ukuprinta kwiindlela zokusebenza kwiindlela zokubona.

Ukuprinta ngokuthekwako kunye nokulandelelana ngokuthekwako kwiindlela ezimbhujwayo kunye ne-3D

Imicabha ye-inkjet yokuphansi kakhulu yavumela ukuguqula inkwaba yokuprinta kuzinto ezinemigqa nezinhloso ezingavisisi ngokuhlanganisa ukulawula ukuxhumiyo nekuhlela kwezinkwaba ngokucophele. Le micabha iyavumela ukugcina inkqubo yokuprinta ngokucophele ngokushintsha izinhloso ezingavisisi ngokusebenzisa izitechnoloji ezifanele.

Imicabha ye-Inkjet Ekuqaleni: Ukucophelela Kukuxhumiyo Kuzinhloso Ezingemigqa

Le micabha esebenzisa izimandla ezinezimotile ukuxhuma izinhloso ezingemigqa (isb., izibhobho, izinhwele) ngenkanda inkwaba iphakeme ngokuphelele 2–10 mm. Le nto ikwenzela ukuba kutholwe okuphakeme kokuqeda 0.05 mm, kuvumela ukuprinta kwezinhloso ngokuphelele ngekudiphomwa. Imicabha enqamkela ukwenza 300–1,200 izinto ngohora futhi iyasebenzela ukulingana kwezinhloso ezingu-15 mm (izinhwele zokucosha) kuya ku-300 mm (izindumba zokusebenza).

Ukuxhumiyo phakathi kokuqala kwezinhloso ne-firing frequency ye-Inkjet

Ukuqhanya phakathi kwe-rotational velocity (RPM) kunye nefiring frequency kuyindlela yokuthiwa yekota kwi-0.1 mm. Encoder-triggered ejection iyavumela ukutshintsha kwezililo encinci zokuvula, ubukeke iphoyinti yemposiso phezulu kwi-2% nangona kwi-500 RPM. Iindlela ezininzi zisebenzisa i-algorithms zokuthatha iiprofita ukuze uvusele ukutshintsha kwezikhala ngokwesicelo-moya torque data.

Isifanekiso: Ukucoda kwezililo ephakeme kwiibhawebhawe zokuthiwa ngokusebenzisa High Drop Inkjet Printers

Ngemfundo yakamuva ye-2023 kwiqoqo lokugcina, izicathami zokugcina zokubhala ngokumgca ngokuphezulu kuzobhalela ngama-40% ngokusheshayo kunye nezicathami zokubhala ngolaser xa kufuneka kubhalelwe amakhodi kule ndinga yamanzini. Okuthandwa ngoko kukuba kuthile kakhulu le data yokugqibela - amanye amanye ayilandelana ngama-99.9% ngale ndawo enqamkqweni. Futhu lokhu, izicathami eziqinileyo ziyahlukana ngokuphezulu kwesikati esinye sekuphela. Ayiyi mawuthu ukuba lokhu kuchitha inkqubo yokugcina izicathami ngama-2/3 xa kuthathwa ikona nezindlela zokugcina ezindala ezingekho mawuthu ngokushesha.

Ukuqhathaniswa kwezicathami nezinto zokugcinwa nokuthuthukiswa kwekuphela kwezinto ezinhlelweni

Ukunqamkqa kwezicathami nokubhala kwezinto ezikhathini ezingaphantsi kwezinto ezingaphansi

Xa kusebenzela nezindawo ezingenakulinganisa, kungcono ukuthi inkhwevha ikhona ngokulinganisa kuyindlela enkulu kakhulu ngokusho kwemithwisto yokuxhuma nezingo zokugcinwa kweyona ngokuhlukileyo kuzindawo ezahlukene. Izindawo eziphansi kakhulu zihlangela inkhwevha ngokuningi futhi kudinga isikhashana eside ukuze lihle liyasele futhi liyasele kakhulu. Okusemaphakathini kusebenzisa okuphawuka okusheshayo kakhulu, kwenza ukuthi inkhwevha ingasebenzi ngokuphelele. Ngokwemibhalo yakamuva ephumalwe kuNature ngoqo, izici ziyahluka ngama-23% ngokusheshayo kuzinto ezinembelela ngaphandle kwezilandelayo. Abasebenzisa inkhwevha uyaya kuthikela lezi nkinga ngokufaka kwezinhlelo zokushusha ngegciwane esibonile noma izinhlayiya zokuvula eziphezulu. Lezi zinhlelo zinesizo lokuthi inkhwevha ikhona ngokulinganisa kuhlanganisa kakhulu kwezindlela ezahlukene.

Izinhlelo Zokuguqula Isayizi Ukuze Kuthuthuke Inkile

Izintathu zokulungisa izinto eziphumelelayo ziyagcina izinhlelo zokusebenza zomnotho:

- Ukugcinwa kweplasma : Iziphakamisa amandla wesayithi nge-40–60 dyne/cm, ukhululela ukulayeka

- Imifusho yekhondla : Ishintsha i-ink contact angle kusuka ku-80° ishane kuma-30° kuzo zepolymers eziphezulu kwezinye

- Ukubonakala okuncane : Izimiso eziyilwe ngalaseri zikhuthaza ukuxhuma kwegesi nge-220%

Isicelo se-2023 sithole ukuthi izinkanu zokuxanda eziyilwe ngaphansi kwezinhlobo zokuxanda zokuxanda kwe-UV zakhuthaze ukuxhuma kwezinhlobo zokuxanda kwe-UV kusuka kwe-85% ishane ku-98% emuva kwesikhathi esine 72 we-humidity testing, fakela amastandadi ase-ISO Class 1.

Isimo: UV-Curable Inks ne-Real-Time Curing kuzo zokuxanda zokuxanda zokuxanda ezinkulu

Ngemfundo ye-Future Market Insights engu-2024, imi inkhwezi ezingaphelileyo kuzo zingxenye ezingu-38 yazo zonke iindlela zokubhala ngokushesha kuzo zokunye today. Le ndhleke ziyahluka kakhulu ngoba zingaphela ngokushesha - ngaphakathi kwe-0.3 seconds - futhi zenza amadot ezingaphansi kwe-2 micrometers even on complex 3D surfaces. Le nqubomkululo eziphezulu ezingama-inkjet zinezinhloso ezingama-LED UV arrays abangela ngokushesha okungenani u-2.5 watts per square centimeter wokulawula ukuphelelwa. Okuthakazelisayo ngale ndleke yindlela abasebenzisa kubuyela kakhulu ukuphakama okuphansi kwe-45 degree Celsius isimo xa kusebenza. Kuzo zonke izindawo eziningi lapho izimboni zingase kuthwale ukuphela ngokuphelelwe, ngqo kuzo ezibhakabhakeni ezifakwe kuzo, kukhona inqubo yokuvumela ukuthayelela okuthinta ngokungaphezu noma ngaphansi kwe-15%. Le teknoloji ethu kubangela abasebenzisi ukuba bafumane iziphumo eziningi zokuthobela, ngu-98% isimo lapho kubhala kuzo izinhlangothi zokuthi zingxenyelwe kuzo ukuphathana okungenani u-0.8 millimeters noma u-3.2 millimeters kuzo zonke izindawo.

Ukufaneleka Okuhle Noma Okuhle Okuhle Kwezinkuva Eziphambene Nezinkuva Ezincane

Izinkuva zokuprinta zokuprinta ezincane zifaka kahle imishini yemfundo yokuxhumana nokuthiwa kwezimali ezinhle. Abasebenzisa inkampani ebonile ukuncipha kwezimali ezinhle ngama-40% ngokusebenzisa imishini yokuhanjiswa okuthiwa kuzindlela ezithile (Ponemon 2023).

Izinhloso Zokufunda Noma Izinhloso Zokuthunyelana Ngekufakelela Okuphezulu Noma Okuphezulu

Izinhloso zokufunda zokuthunyelana kahle zifinyelela ukuphambene kwezinto ezincane ngokusheshayo, zibangela ukuthi izinkuva ziphambene nezindlela ezithile. Lezi zinhloso zisebenzisa izinhloso zokufunda zokuthunyelana kahle ngezindlela ezithile ngaphandle kokuqondiswa ngokwamanje.

Ukufaneleka Kuzindlela Ezithile Noma Ezithile Ezithile

Imicabho ekuhlukene nemibandela yezicelo ezingcono kufanele usebenze ngokuvumelanayo ukuze ikhonde 600 dpi esikhundleni 120 m/min. Kumaqondo awalandelani—njengama-valve noma iziphashi ezingavamile—i-eletrostatik holders enkqubekela ne-3D surface mapping iyaziwa inkqubo yokulayisha amathinta ngokuvumelana noma kungaphandle kweziguquko emncane zokungenkqubo.

Ukuquilashwa Kwezimali Okuphezulu Ngepethini Yokuprinta: Indaba Ebalulekileyo

Indaba iyafuneka ikhona ukwahlukana: ukufumana <0.1 mm ukuthola kwayo noma kuyadinga ukuba kuneempatli zokuphatha kakhulu >90% ngexesha eliphezulu. Izinto ezintsha kwi-MEMS-based micro-nozzles zibonisa ukuba ziyafumana izindlela zokulayisha amadrop 22% ngokushesha ngaphandle kokuthile kwayo—into ebalweyo kwiindaba zase 2023.

Imibuzo Evame Ukubuzwa

Yiyiphi indaba ebalulekileyo yokuprinta kumaqondo awalandelani?

Iindaba ebalulekileyo kuxhomekeke kwayo kuzo inkqubo yokulayisha amathinta, ukuthwala kwekankatha, kunye netime yokulala ayilandeli, okuqinisekisa ukuba kuneempawu zokulula.

Kutheni na iinkqubo zokulayisha amadrop eziphezulu ziyasebenza ngokulula kumaqondo awalandelani?

Amaphrinta we-inkjet enkulu yokuphantsula inkwenkwezi yokuthola izindlela futhi kwenzeke ukulungisa okusheshayo kwezinhlamvu zokuphantsula, kulokho kuvumela ukuthi kuhlangane ngempumelelo nemigqa engenamandla.

Iziphumgo ezimangalisayo ziliphi ezosiza ukuthuthukisa ukugcina kwezinkwezi kumagqamane okuphambene?

Izindlela zokuguqula umgqa njengekuchaze kweplasma, amagqabi amanqina, nokuguqula ngokuncane kwezinhlobo zenhlanganiso ukuthuthukisa ukugcina kwezinkwezi kumagqamane aphambene.

Ukuthi izisindo se-inkjet ephindaphindayo singathola kanjani ukuprinta kumagqamane enkulu?

Izimo eziphindaphindayo zivumela amasipha aphinde futhi zilinde ig distance efanayo ye-printhead, ukufikelela ekugcineni kanye nokubonakala kumagqamane enkulu.

Indaba yezinkwezi ezikwazekileyo kwe-UV kungoti inkjet iprinta leli nini?

Izinkwezi ezikwazekileyo kwe-UV ziphumelela ngokusheshayo futhi zilinde isilinganiso sokuguqula, okwenza wena ngokushesha kumagqamane amathathu, ukuthuthukisa inkawo yokuprinta.

Uhlu Lwezinto Eziqukethwe

-

Ukuthinte Kwezinsawo Ezingaphansi Esikhundleni Sokuphrinta Kwemali Inkjet

- Ukuthwasa Imiphumela Yezindlela Zokuprinta Inkjet Zilandelayo Kuzinsawo Ezibhujwe nezinsawo eziyinkimbinkimbi

- Izinto eziphambeneyo ezingaphambeneyo nokuba kwezinyukelo zokuprinta kwiindlela ezingenakuphumelelwa

- Ukukhawuka kwe-Substrate kuzo Ziziphumo ze-Inkjet Printing: Ukuhlala, Isayizi, futhu I-Geometry

- Iingxelo Ezibalulekileyo kwi-Tech yemoto ye-Inkjet Printer enye kwezindleko ezikhulu

- Ukuprinta ngokuthekwako kunye nokulandelelana ngokuthekwako kwiindlela ezimbhujwayo kunye ne-3D

- Ukuqhathaniswa kwezicathami nezinto zokugcinwa nokuthuthukiswa kwekuphela kwezinto ezinhlelweni

- Ukufaneleka Okuhle Noma Okuhle Okuhle Kwezinkuva Eziphambene Nezinkuva Ezincane

-

Imibuzo Evame Ukubuzwa

- Yiyiphi indaba ebalulekileyo yokuprinta kumaqondo awalandelani?

- Kutheni na iinkqubo zokulayisha amadrop eziphezulu ziyasebenza ngokulula kumaqondo awalandelani?

- Iziphumgo ezimangalisayo ziliphi ezosiza ukuthuthukisa ukugcina kwezinkwezi kumagqamane okuphambene?

- Ukuthi izisindo se-inkjet ephindaphindayo singathola kanjani ukuprinta kumagqamane enkulu?

- Indaba yezinkwezi ezikwazekileyo kwe-UV kungoti inkjet iprinta leli nini?