The Challenge of Non-Planar Surfaces in High Drop Inkjet Printing

Standard inkjet printers have real trouble handling curved surfaces and three dimensional objects because their printheads stay at fixed positions and the way they spray ink works best on flat materials. When printing on round things like beverage bottles or complicated shapes found in industrial components with all sorts of textures, these limitations cause problems with where the ink actually lands. The result? Print quality suffers quite a bit. Manufacturing studies show around 12 to 18 percent more defects when printing on non flat surfaces versus regular flat ones. This makes sense given how limited traditional systems really are when it comes to adapting to different shapes.

Understanding the Limitations of Traditional Inkjet on Curved and 3D Substrates

Three critical factors compound these challenges:

- Ink trajectory deviation: Droplets travel 0.5–3 mm farther on concave surfaces than on convex ones

- Capillary action interference: Surface energy variations exceeding 5 dynes/cm disrupt ink spread

- Drying time inconsistencies: Non-planar shapes create microclimates where drying rates vary by up to 40%

A 2024 fluid dynamics study found that viscosity deviations over 30 cP and nozzle diameters under 50 µm exacerbate these issues, pushing the Ohnesorge number’s reciprocal (Z value) outside the optimal 1–10 range for stable droplet formation.

Key Factors Affecting Inkjet Printing Quality on Non-Flat Surfaces

| Variable | Planar Surface Tolerance | Non-Planar Tolerance |

|---|---|---|

| Drop size | ±2% permissible | ±0.5% required |

| Print gap | 1–2 mm acceptable | 0.3–0.7 mm optimal |

| Substrate angle | 0–5° functional | >15° causes 70% quality loss |

High drop inkjet printers address these constraints through adaptive throw distances (up to 25 mm vs. traditional 5–8 mm) and real-time droplet velocity adjustments.

Substrate Influence on Inkjet Printing Outcomes: Wettability, Texture, and Geometry

When surface energy drops below about 38 mN/m, which is pretty common for most plastics and metal coatings, plasma treatment becomes necessary to get good ink sticking power. For those really rough surfaces where the texture measures over 6.3 micrometers Ra, special printhead designs have been developed that keep nozzle performance above 98% thanks to their clever anti-clog features. Regular printing systems typically only manage between 82 and 88% efficiency in these conditions. What's exciting now is the progress made in contactless printing technology. These new methods produce reliable prints even on materials that curve at angles approaching 120 degrees, all without needing physical contact during the printing process itself.

Core Innovations in High Drop Inkjet Printer Technology

Precision Drop Control and Trajectory Optimization for Surface Variability

The latest generation of high drop inkjet printers relies on piezoelectric actuators to fine tune where ink droplets land as they print. Research published last year looked at how these advanced printing systems perform in factories, and what they found was pretty impressive. Print heads capable of positioning within just under 20 microns managed to place drops accurately about 98 times out of 100 when printing on those tricky curved parts used in car manufacturing. What makes this technology stand out is its ability to handle surfaces that aren't perfectly flat. The printers come equipped with built in laser scanners that can detect height differences of up to 15 millimeters across the work area. This means even if there are slight bumps or dips in the material being printed on, the system maintains good coverage throughout, working effectively on surfaces that tilt at angles varying by plus or minus three degrees from perfectly level.

Printhead Distance and Ink Throw Capability in High Drop Systems

High drop printers operate at 600–1,200 dpi with throw distances of 8–25 mm—40% greater than legacy models. This enables printing on recessed packaging or textured surfaces without sacrificing speed. UV-resistant industrial inks now maintain viscosity stability (<5% variation) across 8–15 mm gaps, supporting throughput rates above 120 m/min.

Nozzle Design and Wettability Effects on Ink Ejection Consistency

Advanced MEMS-fabricated nozzles (40–70 µm diameters) improve consistency through:

- Hydrophobic coatings that reduce ink spread by 22% on low-energy plastics

- Tapered geometries maintaining ±1.5% droplet volume accuracy at 30 kHz firing rates

Research in advanced printer nozzle technologies demonstrates how multi-layered actuator designs achieve 0.1 µL ± 0.005 µL drop control—essential for functional printing on medical devices.

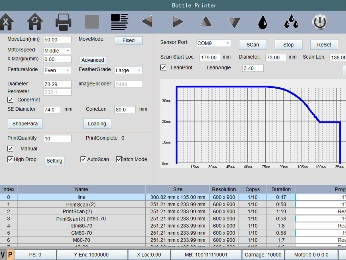

Rotary and Synchronized Printing for Cylindrical and 3D Objects

Advanced high drop inkjet systems have redefined printing on cylindrical and irregularly shaped objects by integrating synchronized motion control with precision ink deposition. These systems overcome traditional limitations through adaptive technologies that maintain print quality across complex geometries.

Rotary Inkjet Systems: Precision in Motion for Cylindrical Substrates

Rotary configurations use motorized mandrels to rotate cylindrical substrates (e.g., bottles, tubes) while printheads maintain a fixed distance of 2–10 mm. This setup achieves ±0.05 mm radial alignment accuracy, enabling full-wrap graphics without distortion. Modern systems process 300–1,200 units/hour and handle diameters from 15 mm (cosmetic tubes) to 300 mm (industrial drums).

Synchronization of Substrate Rotation and Inkjet Firing Frequency

The relationship between rotational velocity (RPM) and firing frequency ensures dot placement accuracy within 0.1 mm. Encoder-triggered ejection compensates for minor speed fluctuations, keeping positional error below 2% even at 500 RPM. Advanced systems employ predictive algorithms to adjust firing timing based on real-time torque data.

Case Study: High-Speed Coding on Beverage Cans Using High Drop Inkjet Printers

According to recent research from the packaging sector in 2023, rotary inkjet systems can actually run about 40 percent quicker than laser marking techniques when it comes to putting codes on those aluminum drink cans. What's interesting is how clear these expiration dates remain too - almost all of them stay legible at around 99.9 something percent on those tricky curved surfaces. And get this, the special UV inks stick completely within half a second flat. Not bad at all considering this approach cuts down on wasted ink by roughly two thirds when we compare it against old school pad printing methods that just aren't as efficient anymore.

Ink-Substrate Dynamics and Drying Optimization on Complex Surfaces

Ink Adhesion and Drying Behavior on Non-Planar Geometries

When dealing with non-flat surfaces, getting ink to stick evenly becomes a real challenge because of how capillary action and surface tension work differently across the surface. Concave spots tend to collect too much ink which takes longer to dry and often leads to bleeding issues. The opposite happens on convex parts where solvents evaporate too quickly, making it hard for the ink to adhere properly. According to recent studies published in Nature last year, droplets actually spread about 23 percent slower on curved materials compared to flat ones. Printers are starting to address these problems by incorporating special drying systems like infrared heaters or powerful air jets. These technologies help keep the ink's consistency within roughly 5% variance even when printing on complicated shapes and contours.

Surface Modification Techniques to Enhance Ink Adhesion

Three substrate optimization strategies dominate industrial workflows:

- Plasma treatment: Increases surface energy by 40–60 dyne/cm, improving wetting

- Primer coatings: Reduce ink contact angle from >80° to <30° on hydrophobic polymers

- Micro-texturing: Laser-etched patterns enhance mechanical bonding by 220%

A 2023 study found plasma-treated aluminum cans improved UV ink adhesion from 85% to 98% after 72-hour humidity testing, meeting ISO Class 1 durability standards.

Trend: UV-Curable Inks and Real-Time Curing in High Drop Inkjet Applications

According to Future Market Insights from 2024, UV curable inks account for around 38 percent of all industrial inkjet formulations today. These inks are really gaining traction because they cure super fast—in just 0.3 seconds—and produce very small dot spreads under 2 micrometers even on complex 3D surfaces. The newer high drop inkjet systems come equipped with LED UV arrays that blast out approximately 2.5 watts per square centimeter of light energy. What's interesting is how these machines manage to keep material temperatures beneath the critical 45 degree Celsius threshold during operation. For those tricky spots where shadows might interfere with proper curing, especially in recessed areas of parts, there's an automatic power adjustment feature that varies intensity by plus or minus 15%. This clever technology helps manufacturers achieve nearly perfect results right from the start, with about 98% success rate when printing on automotive components that have height differences ranging between 0.8 millimeters and 3.2 millimeters across their surface.

Smart Adaptability and Future-Ready High Drop Inkjet Systems

Modern high drop inkjet printers integrate intelligent systems to meet complex manufacturing demands. Leading manufacturers report a 40% reduction in material waste through adaptive technologies that respond to unpredictable surface geometries (Ponemon 2023).

Smart Sensors and Feedback Loops for Automatic Gap and Alignment Correction

Real-time laser triangulation sensors detect substrate curvature down to 5 microns, triggering instant nozzle height adjustments. These systems use AI-driven predictive maintenance models to optimize printhead alignment across more than 20 substrate types without manual calibration.

Adapting to Continuous vs. Discontinuous Curved Substrates

Continuous surfaces like beverage cans require synchronized rotation controls to sustain 600 dpi resolution at 120 m/min. For discontinuous geometries—such as valves or irregular packaging—electrostatic holders combined with 3D surface mapping ensure consistent ink deposition despite abrupt angle changes.

Balancing High Throughput With Print Resolution: An Industry Challenge

The industry faces a critical tradeoff: achieving <0.1 mm registration accuracy while maintaining >90% production line uptime. Recent advancements in MEMS-based micro-nozzles demonstrate 22% faster droplet ejection rates without compromising placement precision—a breakthrough validated in multiple 2023 industry trials.

FAQ

What are the main challenges of printing on non-planar surfaces?

The main challenges include ink trajectory deviation, capillary action interference, and drying time inconsistencies, leading to print quality issues.

Why do high drop inkjet printers perform better on non-planar surfaces?

High drop inkjet printers offer adaptive throw distances and real-time droplet velocity adjustments, allowing them to better adapt to non-planar surfaces.

What innovations help improve ink adhesion on complex surfaces?

Surface modification techniques such as plasma treatment, primer coatings, and micro-texturing enhance ink adhesion on complex surfaces.

How do rotary inkjet systems improve printing on cylindrical objects?

Rotary configurations allow substrates to rotate while maintaining a fixed printhead distance, achieving high precision and quality on cylindrical objects.

What role do UV-curable inks play in modern inkjet printing?

UV-curable inks cure quickly and maintain dot spread consistency, making them ideal for complex 3D surfaces, improving printing efficiency.

Table of Contents

- The Challenge of Non-Planar Surfaces in High Drop Inkjet Printing

- Core Innovations in High Drop Inkjet Printer Technology

- Rotary and Synchronized Printing for Cylindrical and 3D Objects

- Ink-Substrate Dynamics and Drying Optimization on Complex Surfaces

- Smart Adaptability and Future-Ready High Drop Inkjet Systems

-

FAQ

- What are the main challenges of printing on non-planar surfaces?

- Why do high drop inkjet printers perform better on non-planar surfaces?

- What innovations help improve ink adhesion on complex surfaces?

- How do rotary inkjet systems improve printing on cylindrical objects?

- What role do UV-curable inks play in modern inkjet printing?