The Power of Combining Screen Printing and Hot Stamping

How Screen Printing Complements Metallic Gilding

When screen printing meets metallic gilding, magic happens for design work. Screen printing creates a solid foundation that really holds up under hot stamping applications, letting those metallic colors stand out like they're shouting from the page. The combination opens doors for complex designs with real depth, giving printers access to all sorts of rich metallic ink effects that just grab attention. Print shops often start with screen printed colors first, then add metallic touches on top. This approach doesn't just look good either it actually feels different to the touch, creating something special that catches both eyes and fingers alike.

Hot Stamping Techniques for Enhanced Texture

When it comes to product aesthetics, hot stamping brings something special to the table by adding texture and depth that makes items look higher quality than they actually are. Designers often incorporate different stamping approaches during planning stages because these methods boost visual appeal while keeping production costs pretty much the same as standard processes. The trick lies in knowing exactly what pressure levels work best for each material type along with proper heat settings. For instance, too much heat on leather might ruin the finish completely. Getting this right means customers get both good looks and satisfying touch when handling products. Many manufacturers have found that incorporating these techniques leads to better customer satisfaction ratings across multiple product categories.

Applications in Luxury Packaging & Apparel

Luxury brands often turn to screen printing paired with hot stamping when they want to create those eye-catching designs that make their products stand out from the rest. These mixed methods show up all over premium packaging materials, helping grab attention at stores and build that loyal customer base over time. Fashion labels have caught onto this trick too. Think about those fancy logos on designer jackets that catch light just right – they're not just there for looks. The texture and shine actually signal something deeper to shoppers who know what quality means. When people see clothing with those special finishes, it tells them this isn't your average stuff off the rack. That's why so many top names invest heavily in getting these printing details just right, because customers start linking those visual cues directly with the brand's reputation for being exclusive and top notch.

Screen Printing vs. Direct-to-Garment (DTG) Alternatives

When to Choose DTG Printers for Small Batches

For companies that specialize in custom designs and run smaller batches, Direct-to-Garment (DTG) printers work really well. The technology produces incredibly detailed prints that stand out, which matters a lot when customers want something unique. Another big plus? No setup time needed at all. That means getting specialty items ready fast without sacrificing print quality. What's interesting about DTG printers is how versatile they actually are. They handle various fabric types much better than old school screen printing does. From simple shirt personalization to those one-off designs nobody else offers, having a DTG printer in place lets small operations keep up with all sorts of customer requests without breaking a sweat.

Advantages of Screen Printing for Metallic Inks

When it comes to working with metallic inks, screen printing gives some real advantages. The process applies ink much thicker than other methods, which creates that shiny, almost mirror-like finish people love so much. Screen printed designs tend to last longer too something that matters because digital textile printing (DTG) often struggles with keeping metallic colors looking good after repeated washing. What makes screen printing really special is how flexible it gets when mixing different metallic shades together. Manufacturers can experiment with combinations that just aren't possible otherwise, leading to all sorts of creative looks on clothing and accessories. Beyond just looking great, these screen printed metallic designs stand up better over time, which explains why many fashion brands still prefer this technique for creating those bold, attention grabbing pieces that stay stylish wash after wash.

Inkjet Printers for Custom Bags: A Hybrid Approach

The advent of inkjet printing has changed how people make custom bags big time, especially since these machines offer such rich colors that open up all sorts of creative avenues. Many businesses are now mixing inkjet with traditional screen printing methods to get products that customers can personalize, which tends to boost their bottom line pretty well. What makes this combo work so well is that it allows manufacturers to create bags with interesting textures and special finishes that just weren't possible before. Companies that combine both technologies end up making really stand out items in the marketplace. These days shoppers want things that feel special and one-of-a kind, so this approach hits all the right notes for modern consumers looking for something different from mass produced goods.

Optimizing Workflows with Combined Printing Technologies

Sequencing Hot Stamping and Screen Printing Layers

Getting the most out of hot stamping and screen printing workflows requires smart sequencing of these processes to cut down on wasted materials. A good color separation setup really helps streamline the design process, letting us plan exactly where each stamp goes before hitting the print stage. The payoff? Better looking products overall while saving on ink and substrate costs. We also need to keep an eye on how long things dry between layers since rushing this step can ruin everything downstream. When someone takes time to map out the whole workflow properly, they end up with sharper details and brighter colors that actually satisfy what customers want rather than just meeting basic specs.

Material Compatibility: Fabrics to Rigid Substrates

Getting to know how different materials behave matters when picking substrates for hot stamping jobs or screen printing work. Take plastic versus paperboard for instance they respond completely differently to heat and pressure during these processes. That's why many shops spend time testing out what works best together before going full scale production. The way inks stick and how foils look actually varies quite a bit depending on what surface they're applied to, so this testing phase really saves headaches down the line. When manufacturers play around with different material combinations and watch how they interact with specific inks and foil types, they end up creating better looking products that perform reliably in the marketplace too.

Curing Processes for Multi-Technique Designs

When working with multi technique printing, different methods require their own unique curing times and temps that need to be factored right into the design process from day one. Getting the curing right makes all the difference when it comes to how long printed materials last and hold up against wear and tear something customers definitely notice. Training staff properly on these curing techniques isn't just nice to have it's essential if we want every product coming off the line to meet quality standards consistently. When workers really understand how to apply these curing processes correctly, they end up with fewer defective pieces and stronger final products that stand up better in everything from packaging to signage applications across various industries.

Choosing Equipment for Multi-Process Production

Industrial vs. Small Business Solutions

Picking out printing gear requires knowing what separates industrial machines from those made for smaller shops. Big industrial printers are built for when there's tons of stuff to print all the time, so they work best in places that have steady, heavy workloads day after day. Small business options tend to flex more and adapt better, which actually saves money for companies whose printing needs go up and down depending on season or project. Looking at how much something costs versus how much gets printed helps figure out what makes sense. Also important is thinking about who will be operating the machine. If staff isn't trained well or lacks experience, even the fanciest printer might become frustrating fast because nobody knows how to get the most out of it.

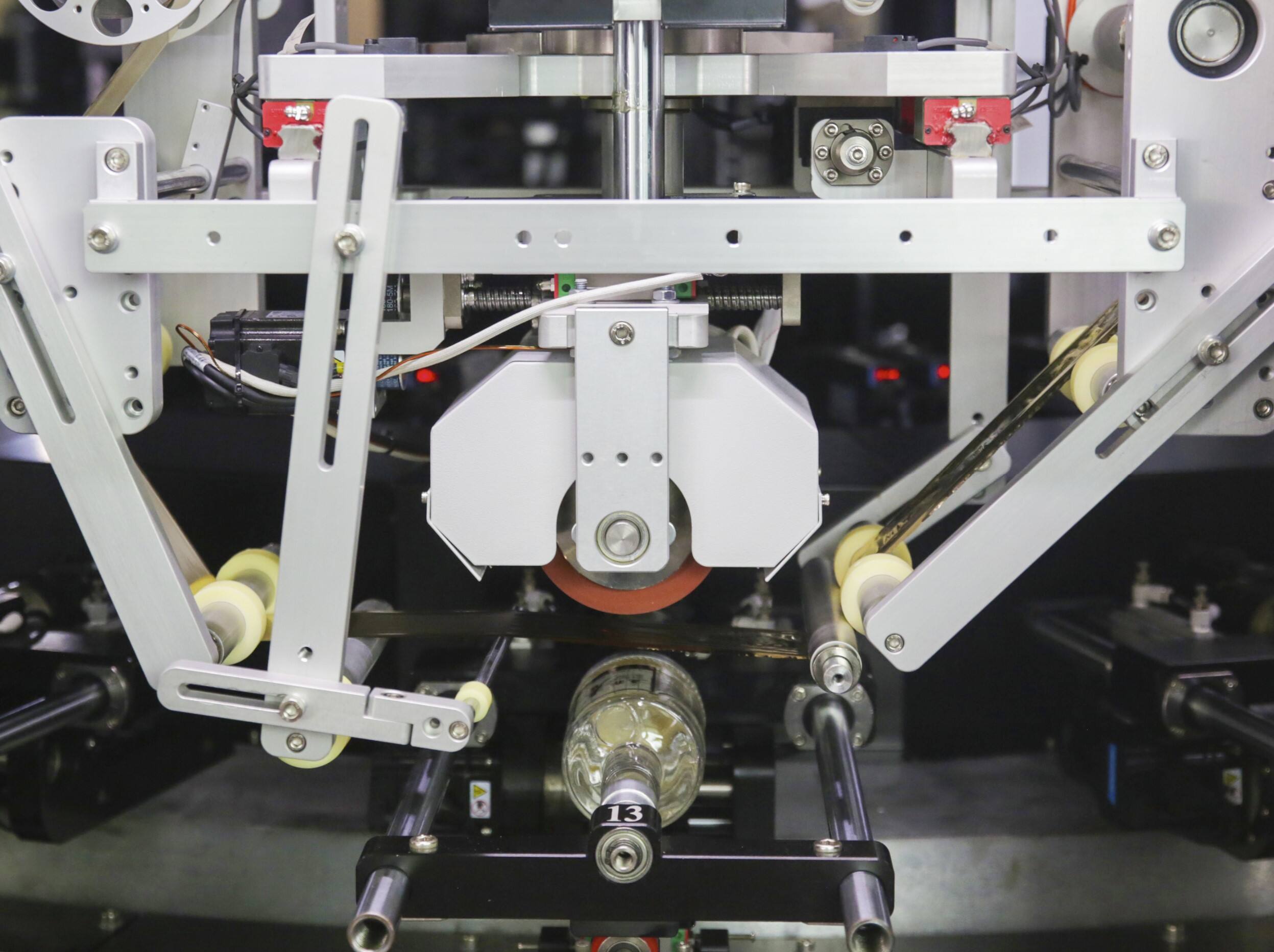

Automation Features for Consistent Gilding

Adding automated features to printing equipment makes a real difference in both the quality and speed of the gilding process. Today's machines come with built-in systems that keep pressure and temperature steady during operation something absolutely necessary for getting good hot stamping results. When manufacturers automate these settings, they cut down on how long things take to produce while at the same time reducing those annoying variations that happen when conditions fluctuate. Smart machine configurations can actually adjust themselves based on what kind of material is being worked on, whether it's paper stock or plastic film, making fine tune adjustments that really improve the final look. The whole point here is using tech smartly so print shops get consistently great results every single time through their presses.

Maintenance Considerations for Dual Systems

Keeping dual printing systems running smoothly requires regular maintenance, which extends their useful life considerably. When companies create specific maintenance plans for each type of printer technology, they avoid those frustrating breakdowns that stop production cold. For instance, neglecting inkjet printers might result in clogged nozzles while ignoring laser units could lead to paper jams or toner issues. Training employees properly on how to handle these routine checks makes a huge difference too. Staff who know what to look for during inspections save money in the long run because problems get caught early before they escalate into expensive repairs. Well-trained teams also work faster when something does go wrong, so production stays on track without compromising print quality across all jobs.