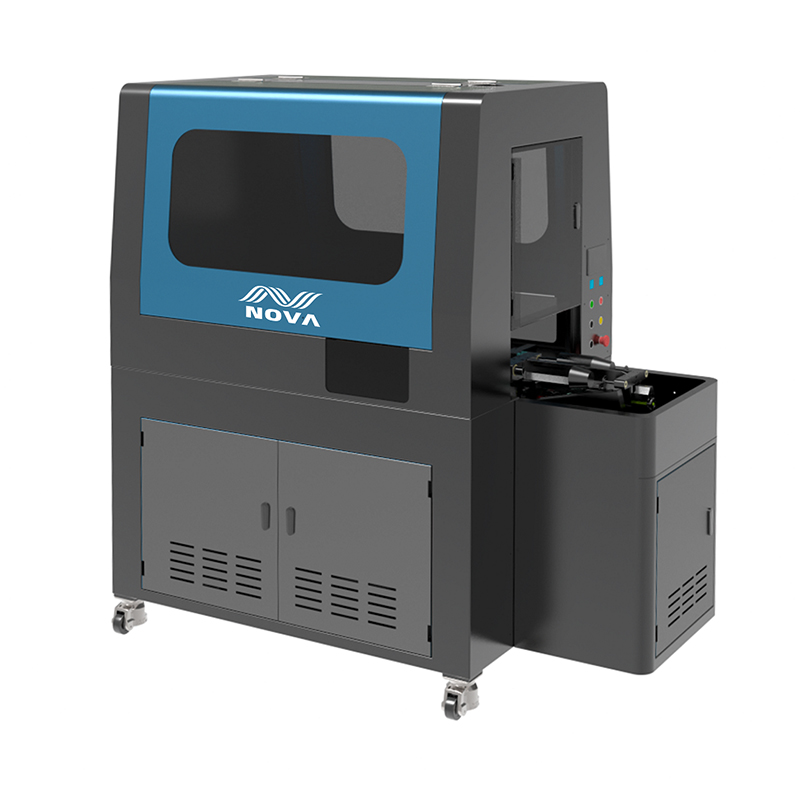

In the competitive cosmetic industry, precision and aesthetics are paramount, and an inkjet printer for cosmetic bottles stands as a cornerstone of efficient and high-quality labeling. Xiamen Luhua jie Digital Technology Co., Ltd., a pioneer in printing solutions, has engineered specialized inkjet printers tailored to meet the unique demands of cosmetic bottle decoration. These printers leverage cutting-edge inkjet technology, harmoniously integrating advanced features to deliver crisp, durable, and visually striking prints on various cosmetic bottle materials, including glass, plastic, and acrylic. Whether it’s intricate logos, ingredient lists, batch codes, or decorative patterns, our inkjet printer for cosmetic bottles ensures exceptional accuracy even on curved or irregular surfaces. The incorporation of AI scanning technology allows for real-time adjustment, ensuring consistent print quality across batches, which is crucial for maintaining brand integrity in the cosmetic sector. Additionally, the printer supports a wide range of inks, including UV-curable options that offer resistance to water, chemicals, and fading, ensuring that the labels remain vibrant and intact throughout the product’s lifecycle. From small vials to larger cosmetic containers, this printer adapts seamlessly to different bottle sizes and shapes, providing manufacturers with the flexibility needed to keep up with evolving market trends. By combining innovation with reliability, our inkjet printer for cosmetic bottles empowers cosmetic brands to enhance their product presentation, strengthen brand identity, and streamline their production processes.