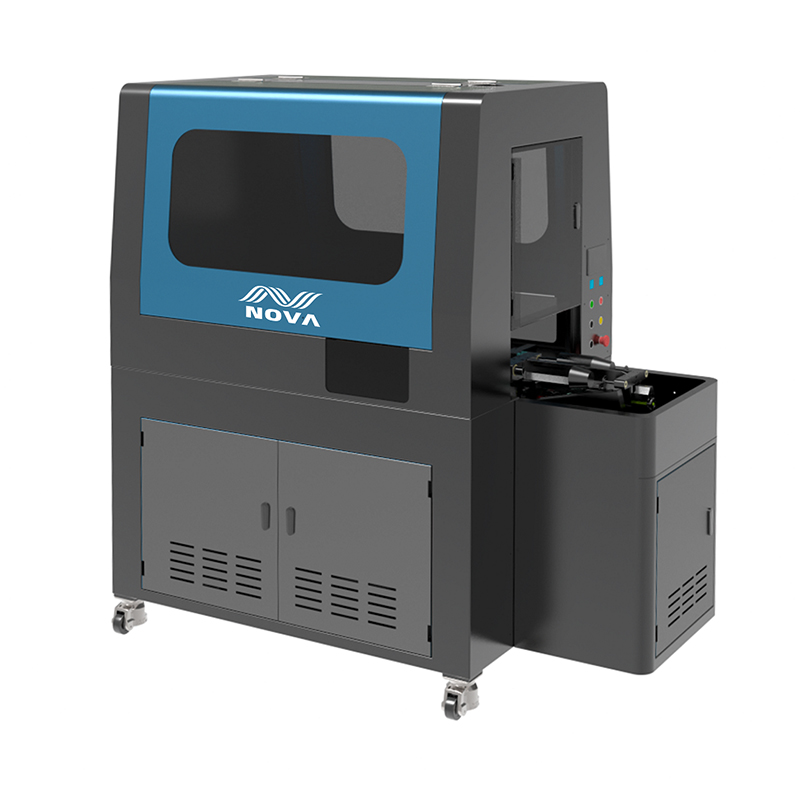

Xiamen Luhua jie Digital Technology Co., Ltd. introduces its specialized inkjet printer for food bottles, a cutting-edge solution designed to meet the stringent printing requirements of the food industry. Food bottles are subject to strict regulations regarding safety, hygiene, and labeling, and this printer is engineered to deliver high-quality, compliant prints that meet these standards. The inkjet printer for food bottles is designed to handle a wide range of food bottle materials, including glass, plastic (PET, HDPE, PP), and metal. It utilizes food-grade inks that are non-toxic, odorless, and compliant with international food safety standards such as FDA and EU 10/2011. These inks are formulated to adhere strongly to the bottle surfaces, ensuring that the printed information, such as product names, ingredients, nutritional facts, expiration dates, and batch codes, remains legible and intact throughout the product's lifecycle. Advanced AI scanning technology is integrated into this printer to ensure precise printing alignment and consistent quality. It can detect the bottle's shape, size, and surface conditions, making real-time adjustments to printing parameters to accommodate any variations. This results in sharp, clear prints with accurate color reproduction, enhancing the visual appeal of the food bottles and improving brand recognition. The printer's high-speed printing capabilities make it suitable for high-volume production lines, ensuring that businesses can meet tight production deadlines. It also supports variable data printing, allowing for easy customization of labels for different product batches or regional markets. With its user-friendly interface and easy integration with existing production systems, the inkjet printer for food bottles minimizes downtime and training costs, making it a reliable and efficient solution for food packaging operations.