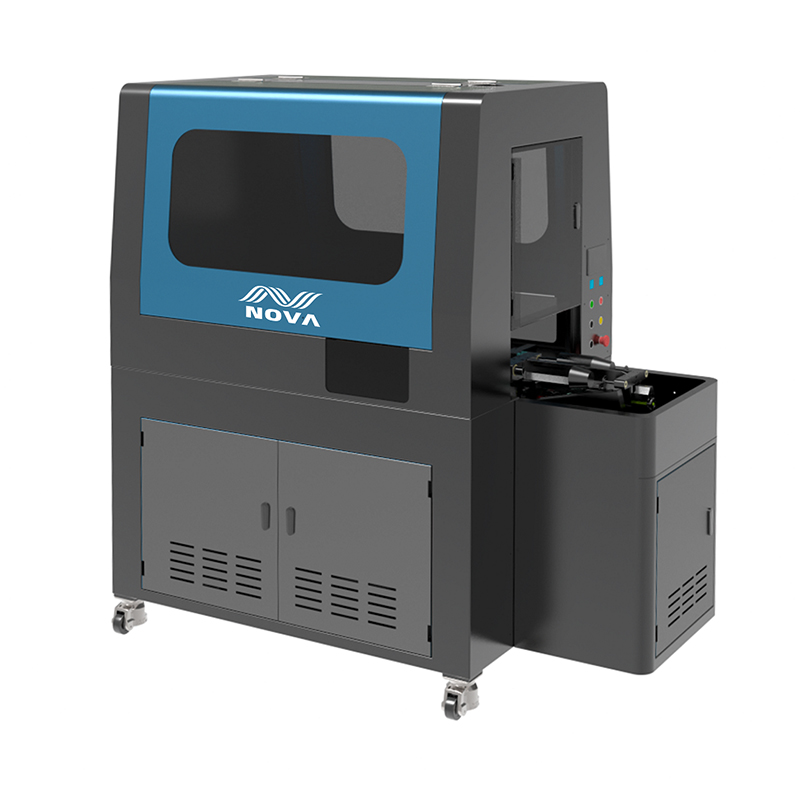

Ceramic bottles are prized for their elegance and durability, but they present unique challenges for printing due to their porous and uneven surfaces. An inkjet printer for ceramic bottles from Xiamen Luhua Jie Digital Technology Co., Ltd. is specifically engineered to overcome these challenges, combining advanced one-pass and AI scanning technologies to deliver stunning results. Our inkjet printers for ceramic bottles use specialized inks formulated to penetrate the ceramic surface, ensuring long-lasting adhesion and resistance to fading, scratching, and moisture. This makes them ideal for decorating ceramic bottles used in the beverage, perfume, and home decor industries, where both aesthetics and durability are important. The AI scanning technology integrated into these printers allows for precise detection of the ceramic bottle’s contours, ensuring that the printed design is perfectly aligned, even on handcrafted or irregularly shaped bottles. The high-resolution printing capabilities enable the reproduction of intricate patterns, gradients, and fine details, capturing the unique texture of ceramic while enhancing its visual appeal. Additionally, the printers are designed to handle the heat resistance requirements of ceramic, with inks that can withstand firing processes if needed. Our inkjet printers for ceramic bottles offer a cost-effective alternative to traditional ceramic decoration methods such as hand painting or decals, reducing production time and enabling greater design flexibility, helping businesses create distinctive ceramic packaging that stands out in the market.