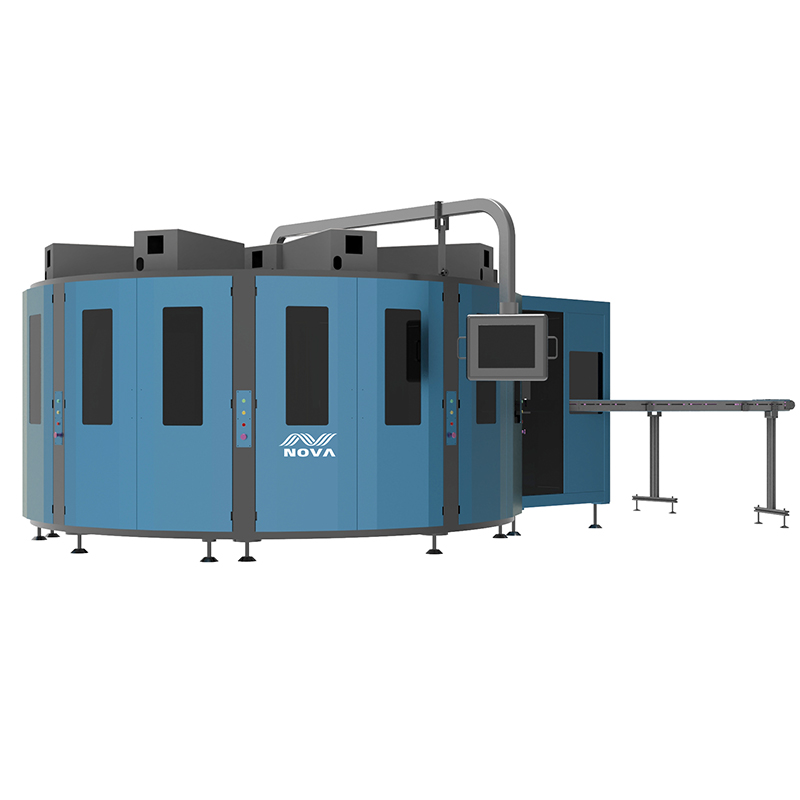

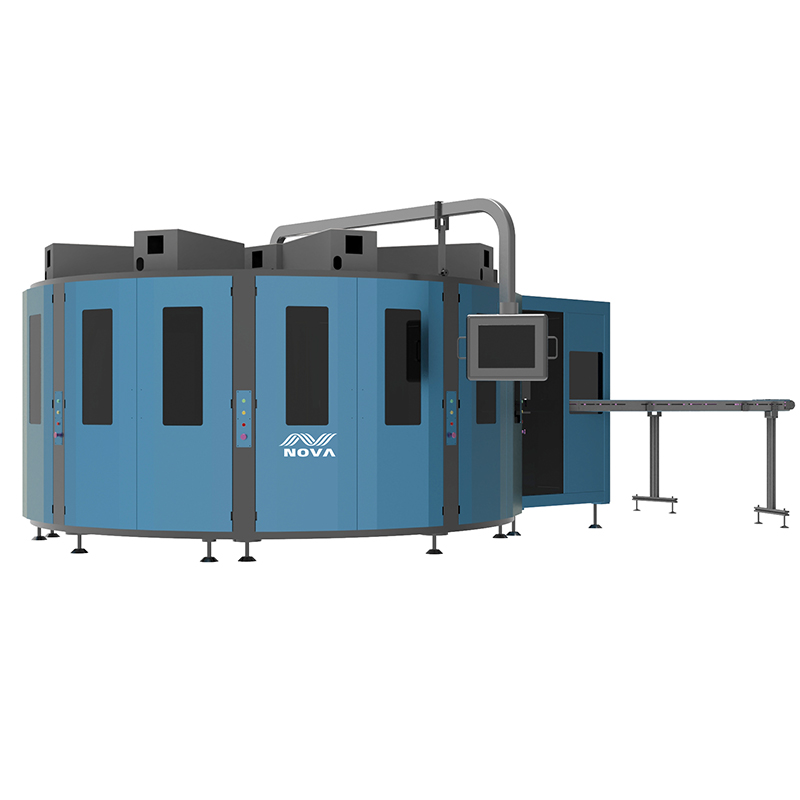

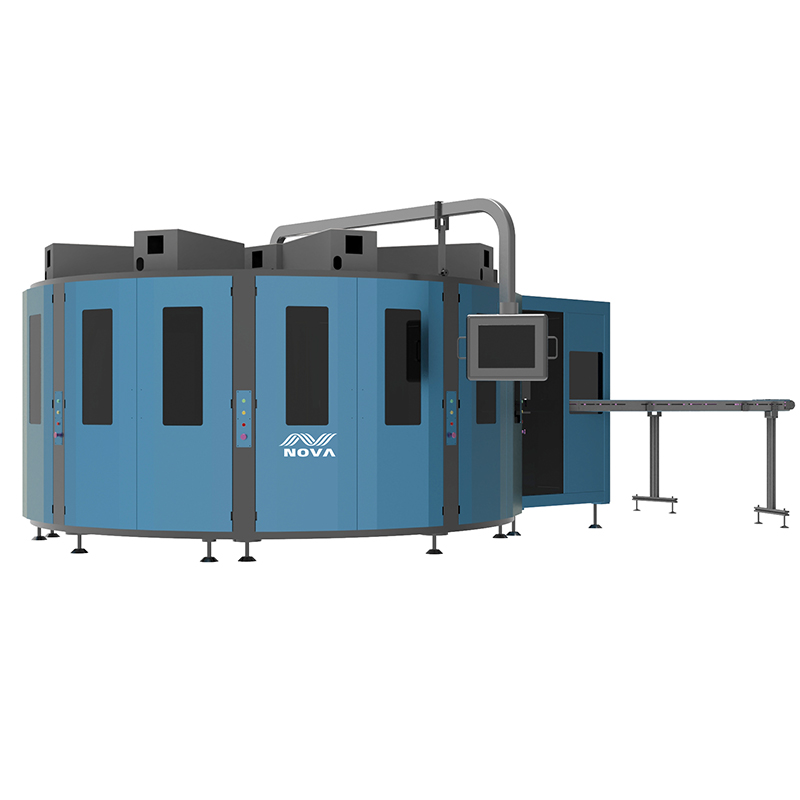

A flatbed inkjet printer with a vision system represents the pinnacle of precision and automation in digital printing, leveraging advanced imaging and machine learning technologies to redefine what’s possible in substrate printing. The vision system, comprising high-resolution cameras and sophisticated image processing software, acts as a comprehensive quality control and alignment tool throughout the printing process. Before printing begins, the system scans the entire flatbed surface to detect the exact position, dimensions, and any irregularities of the substrate, ensuring that the print job is perfectly aligned—even if the substrate has been placed slightly off-center or has minor distortions. During printing, the vision system continuously monitors the print in real-time, comparing it to the digital design file to identify and correct any discrepancies, such as color variations or misalignment, on the fly. This real-time feedback loop ensures that each print meets the highest quality standards, reducing waste and rework. The vision system also enables the printer to handle complex tasks such as printing on substrates with pre-existing patterns, logos, or features, as it can accurately map the new design to fit around these elements. Whether working with rigid materials like metal or glass, or flexible substrates like fabric or vinyl, the flatbed inkjet printer with a vision system delivers consistent, high-precision results. This technology is particularly valuable for industries such as electronics, where precise component marking is essential, automotive for part identification, and custom manufacturing for intricate designs. By combining the versatility of flatbed printing with the intelligence of a vision system, this printer empowers businesses to take on more complex projects with confidence, 提高