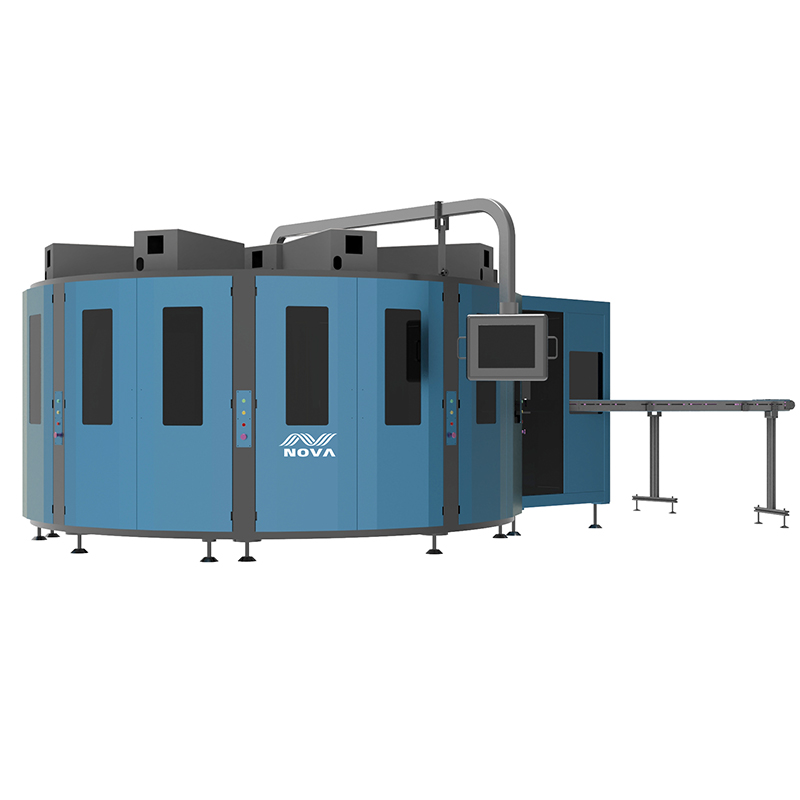

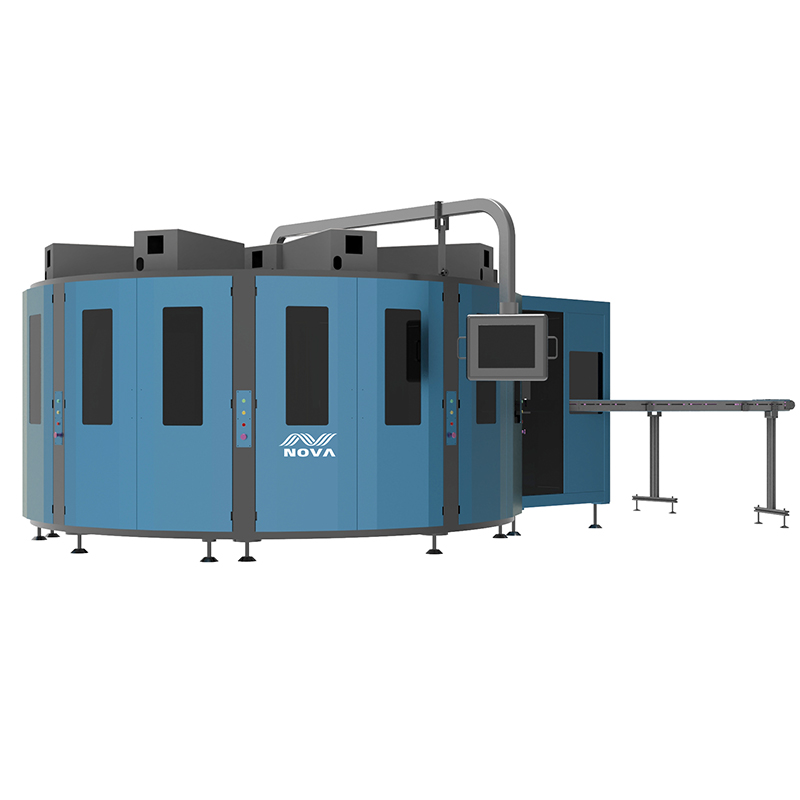

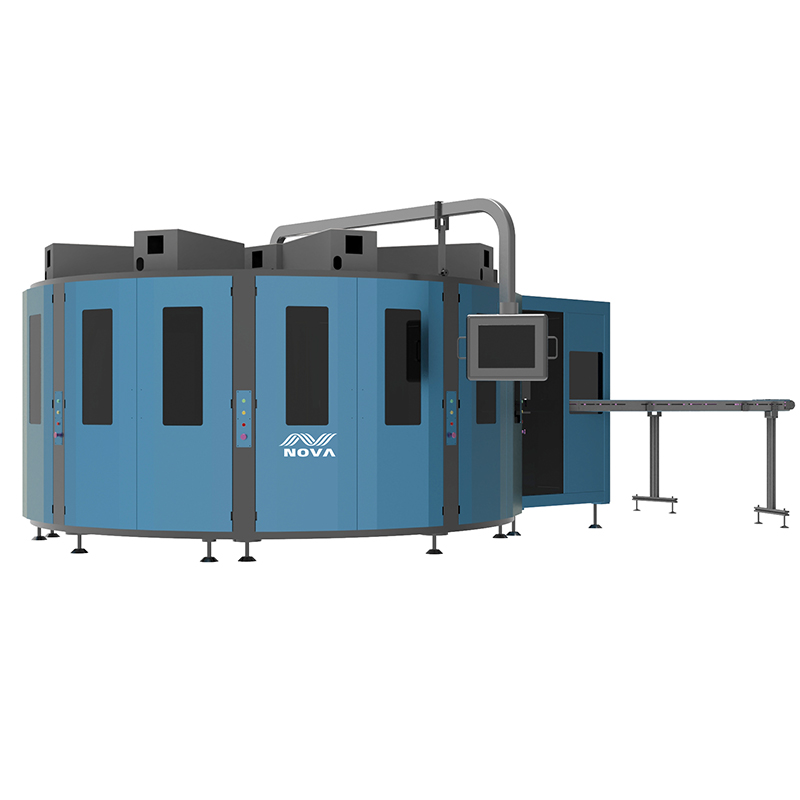

Плоскопечатний струминний принтер із візуальною системою є вершиною точності та автоматизації в цифровому друці, використовуючи передові технології візуалізації та машинного навчання, щоб переосмислити те, що можливо в друку на субстратах. Візуальна система, що складається з камер високої роздільної здатності та потужного програмного забезпечення для обробки зображень, виступає як комплексний інструмент контролю якості та вирівнювання протягом усього процесу друку. Перед початком друку система сканує всю площину робочого столу, щоб виявити точне положення, розміри та будь-які нерівності субстрату, забезпечуючи таким чином ідеальне вирівнювання завдання друку — навіть якщо субстрат розташований трохи не по центру або має незначні спотворення. Під час друку візуальна система безперервно відстежує процес у реальному часі, порівнюючи його з цифровим файлом дизайну, щоб виявити та виправити будь-які відхилення, такі як зміни кольору або невідповідність вирівнювання, безпосередньо в процесі. Цей зворотний зв’язок у реальному часі забезпечує відповідність кожного друку найвищим стандартам якості, зменшуючи відходи та потребу у переділці. Візуальна система також дозволяє принтеру виконувати складні завдання, такі як друк на субстратах із наявними візерунками, логотипами чи іншими елементами, оскільки він може точно нанести новий дизайн, узгоджуючи його з цими елементами. Незалежно від того, чи ведеться робота з жорсткими матеріалами, такими як метал чи скло, чи з гнучкими субстратами, як-от тканина чи вініл, плоскопечатний струминний принтер із візуальною системою забезпечує стабільні та високоточні результати. Ця технологія має особливе значення для таких галузей, як електроніка, де важливе точне маркування компонентів, автомобільна промисловість — для ідентифікації деталей, а також виробництво на замовлення — для реалізації складних дизайнів. Поєднуючи універсальність плоскопечатного друку з інтелектом візуальної системи, цей принтер надає підприємствам можливість упевнено братися за реалізацію більш складних проектів.