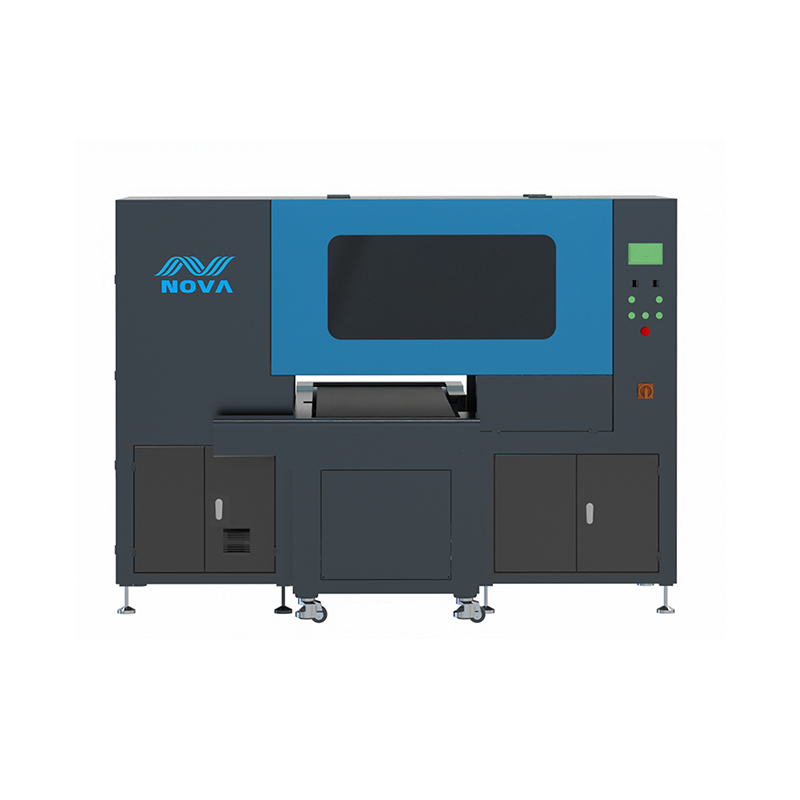

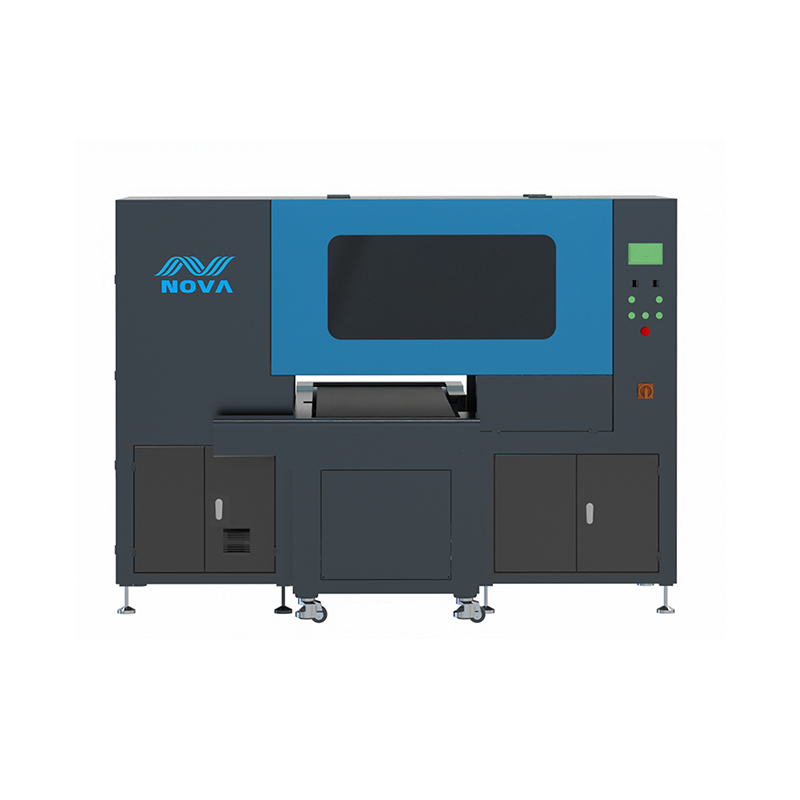

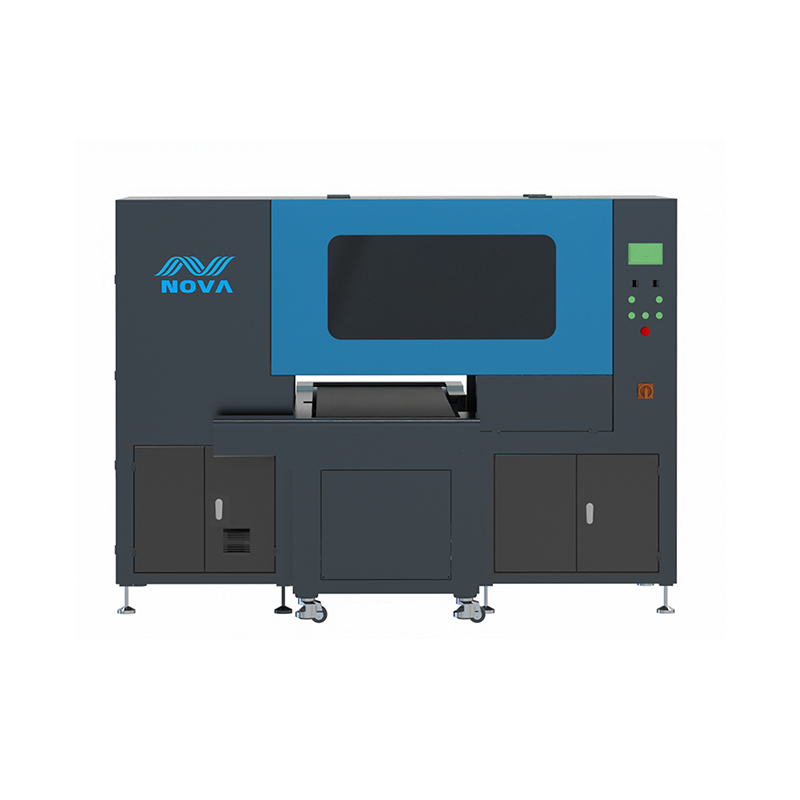

The Most Efficient Way to Save Time and Money on Printing.

Compared to other printing methods, our DTG inkjet printers drastically save time and costs. DTG printing does not require any complex and expensive setup procedures as with screen printing. Because no screens need to be made for every color, setup takes a fraction of the time and costs. In addition, the printers are very efficient in the use of ink. Ink waste is minimized, resulting in lower costs overall. With the ability to print at high speeds, job completion is much faster. This not only improves productivity, but also increases profitability. From custom small-scale businesses to large volume production facilities, our printers are guaranteed to save you valuable resources while helping you meet tight deadlines.