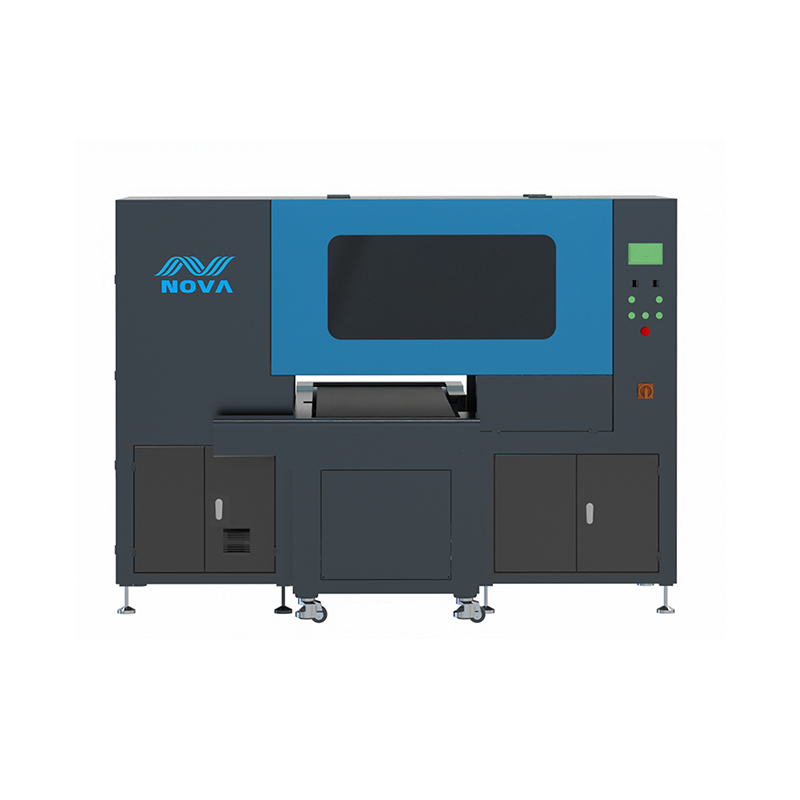

The direct to garment printer (DTG) has revolutionized the textile industry, and Xiamen Luhua jie Digital Technology Co., Ltd. offers a cutting-edge solution that combines speed, quality, and versatility for fabric printing. Unlike traditional screen printing, which requires time-consuming setup and is cost-prohibitive for small batches, our direct to garment printer allows for direct ink application to fabric, enabling on-demand printing with minimal preparation. This makes it ideal for custom apparel, promotional items, and small-batch production runs, where flexibility and quick turnaround are key. The printer uses water-based, eco-friendly inks that penetrate the fabric fibers, resulting in soft, breathable prints that are comfortable to wear and resistant to fading after washing. High-resolution print heads deliver sharp details and vibrant colors, accurately reproducing complex designs, photographs, and gradients—something that is challenging with traditional methods. Our DTG printer is compatible with a wide range of fabrics, including cotton, polyester, and blends, with adjustable settings to optimize print quality for each material type. The user-friendly interface allows for easy design upload and print management, while advanced features such as automatic fabric detection and ink level monitoring streamline the printing process. For businesses in the fashion, promotional, or personalized goods sectors, this direct to garment printer offers a cost-effective and efficient way to meet customer demands for unique, high-quality apparel.