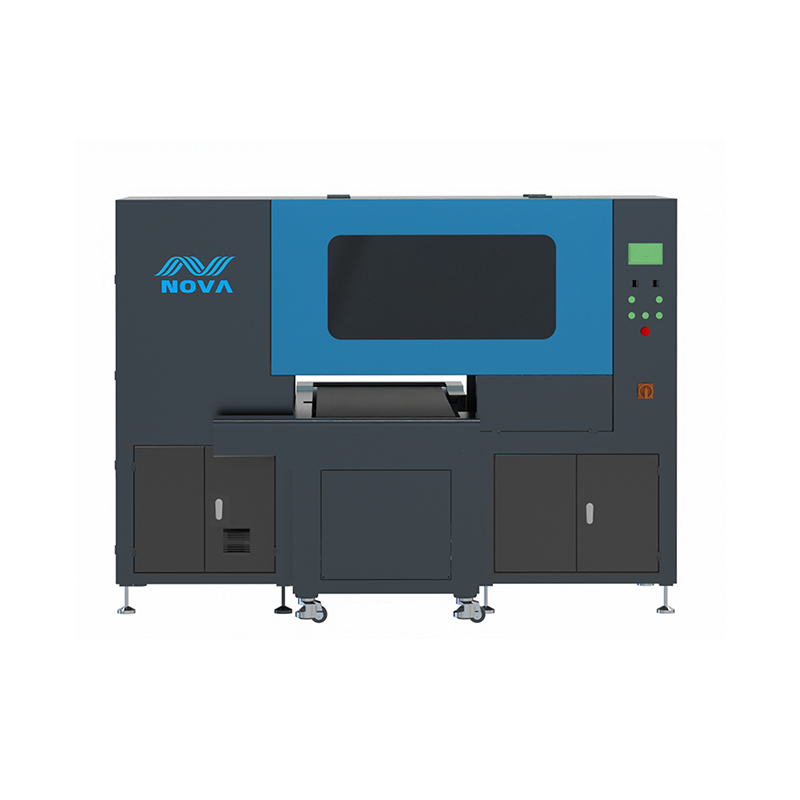

The dtg printer for promotional products is a strategic asset for businesses aiming to create eye-catching, customized promotional items, and Xiamen LuhuaJie Digital Technology Co., Ltd. has developed this printer to excel in the dynamic world of promotional marketing. Promotional products, ranging from t-shirts and caps to bags and aprons, serve as powerful brand ambassadors, and the ability to print high-quality, personalized designs on these items is crucial for making a lasting impression on customers. This specialized dtg printer is engineered to handle the diverse range of fabrics commonly used in promotional products, ensuring consistent and vibrant prints across different materials. Whether it's a cotton tote bag, a polyester polo shirt, or a blend fabric cap, the printer delivers sharp logos, vivid graphics, and clear text that resist fading and maintain their integrity even after multiple washes. This durability is essential for promotional products, as they are often used repeatedly, and a well-printed item can enhance brand recall over time. Another key feature of the dtg printer for promotional products is its speed and efficiency, which is vital for meeting tight deadlines in promotional campaigns. The printer can produce multiple customized items in a short period, allowing businesses to quickly respond to market demands, launch timely promotions, and capitalize on seasonal opportunities. Additionally, the ability to print small batches cost-effectively makes it ideal for targeted marketing efforts, where personalized promotional items can be tailored to specific customer segments, increasing engagement and conversion rates. Furthermore, the printer's compatibility with advanced design software enables businesses to unleash their creativity, experimenting with intricate patterns, gradients, and photorealistic images. This flexibility allows for the creation of unique promotional products that stand out in a crowded market, helping brands differentiate themselves and leave a memorable mark on their audience. With its focus on quality, efficiency, and creativity, the dtg printer for promotional products is an indispensable tool for businesses looking to elevate their promotional strategies and drive brand growth.