Гнучкі можливості друку на різних підкладках

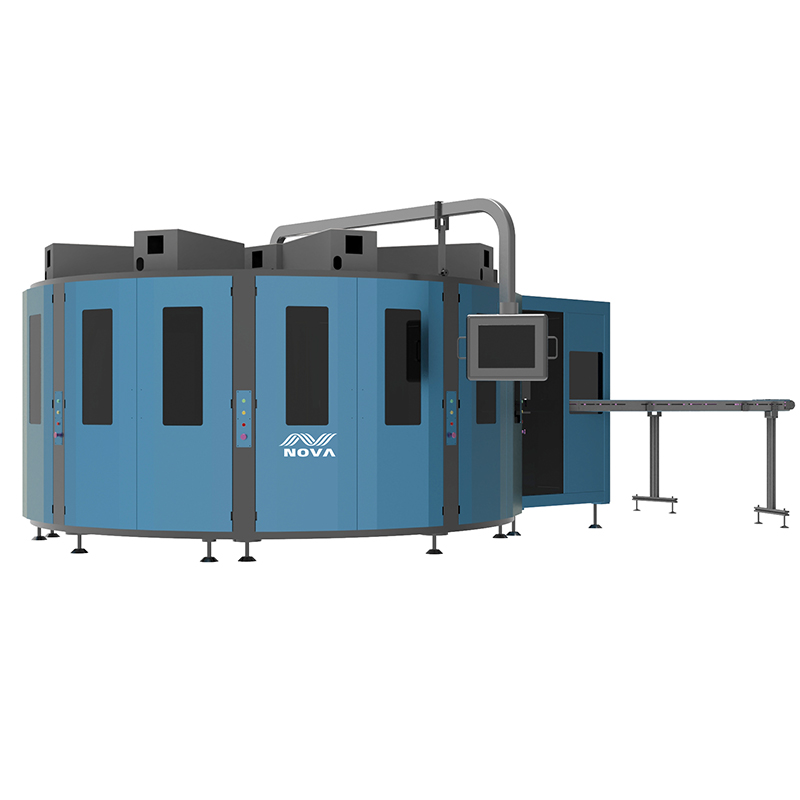

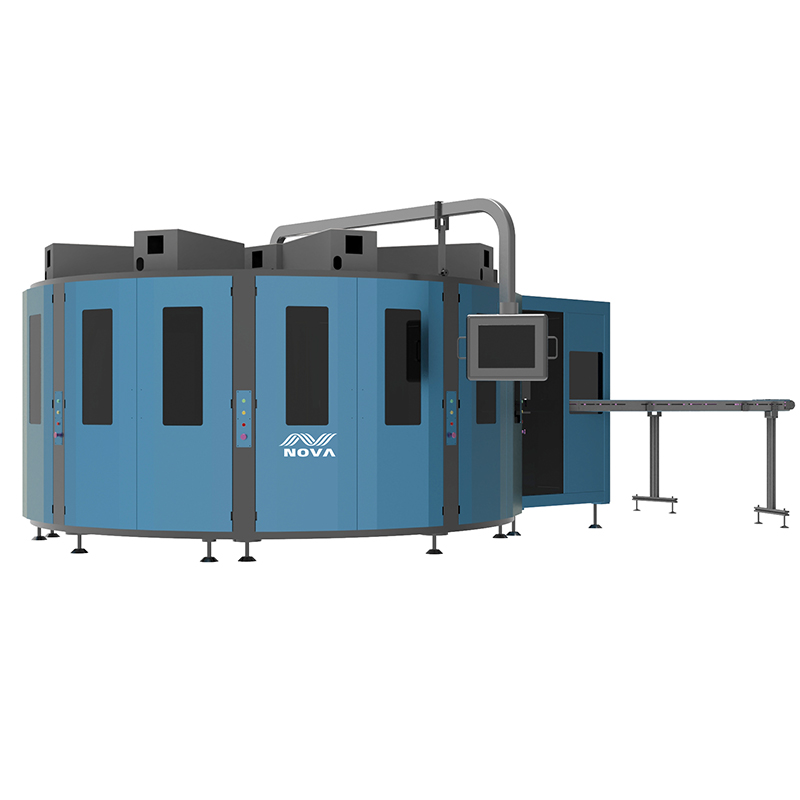

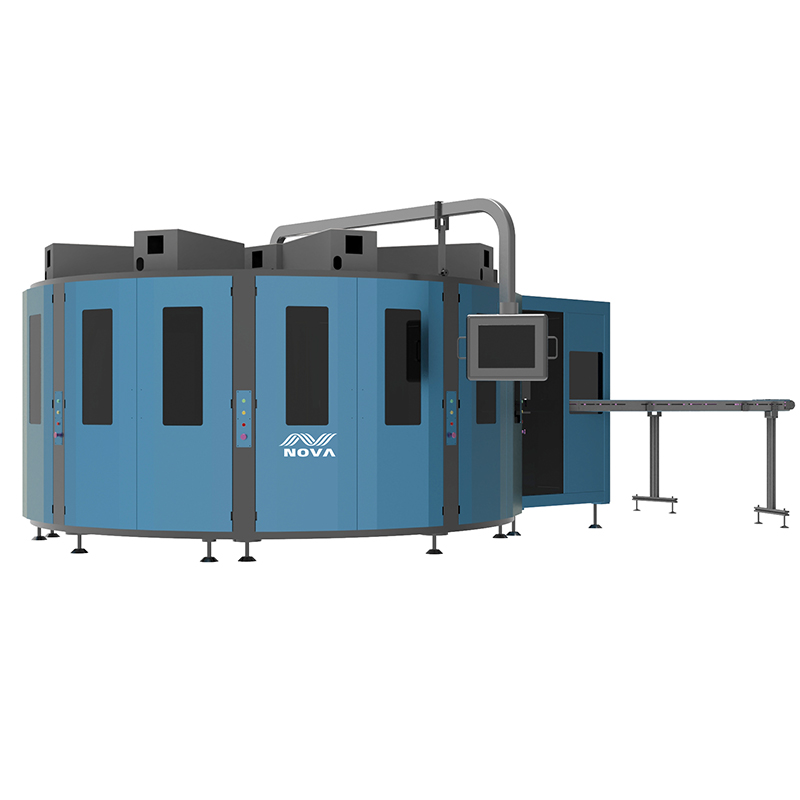

Наша плоскоформатна інкжетна друкарня оснащена камeroю, що робить її універсальною для різних матеріалів. Друкарня здатна друкувати на різних матеріалах з різною товщиною, текстурою та формою. Камера дозволяє друкарні адаптуватися до властивостей кожного матеріалу, щоб забезпечити правильне прилипчення фарби та якість друку. Наприклад, друк може бути виконаний на товстому картоні, який використовується для упаковки, на склі, яке гладке і використовується для декору, або просто на гнучких тканинах. Усі ці фактори дозволяють бізнесу розширювати свій каталог продукції та задовольняти різні клієнтські потреби, що робить їх більш конкурентоспроможними в галузі.