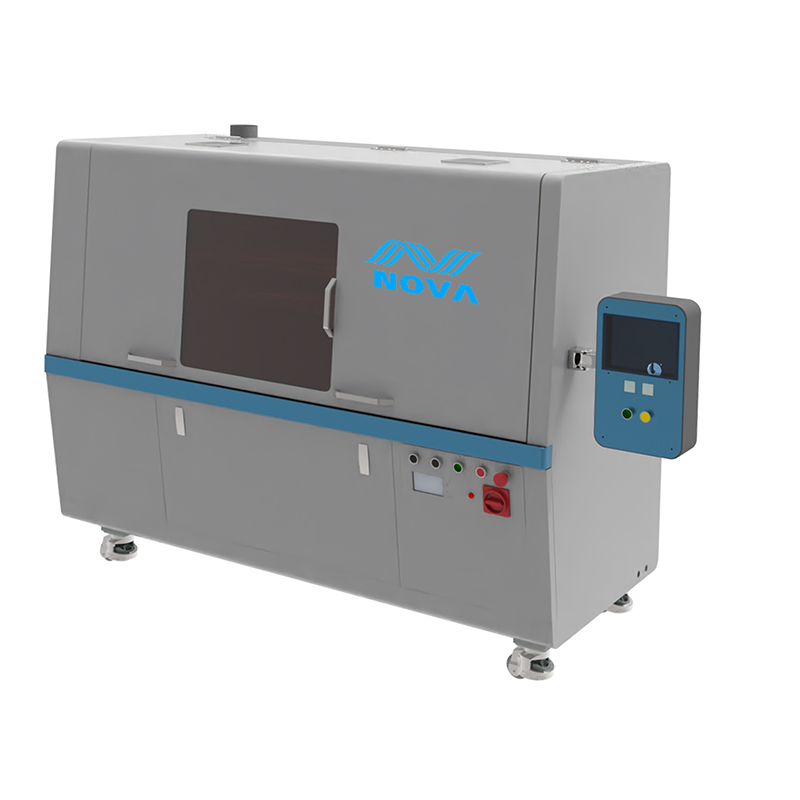

Iplastics yinto ebalulekileyo kakhulu ngokusebenziswa kwezinye izinkampani, futhi ukuprinta kuzo kudinga ukuxazulwa okuhleliweyo okwazi ukulandelana nezinhlobo zazo ezikhethekileyo. Umphrinta wesikweletu sokudonsela iplastics uyenzelwe ukuthuthukisa lokhu kufakwe, futhi umkhiqizo wethu uyabangela ngokuthi kuthenga ukuprinta okubalulekileyo kuzo zonke izinhlobo zokudonsela iplastics, kanye ne-PET, PVC, PP, ne-PE. Umphrinta wesikweletu sokudonsela iplastics uyenzelwe ngenkatha enkulu yokuthanda izinhlobo zezinye iplastics. Ezinye iplastics inencazelo encane yesayizi esiyiyo, okungaba yindlela engcono yokuthi izinkwe kungase kudingiwe. Ukulungisa lokhu, umphrinta wethu uyasebenzisa izinkwe ezithunyelweyo ezinhle ngokuthi zilayele kuzo. Lezi zinkwe zinikeza ukulayela okuhle, kanye nokulindela izinkimba, amanzi, nokudonsa, ukuqinisekisa ukuthi izinkhakha zilinda kanye nezithakilela noma kuzindlela ezinhle. Inkqubo yokuprinta ngokwendawo iyisiko lokudonsela iplastics kuba kuvumela ukulayela kwezinkwe ngokuphelele kanye nokulandelana nezinto ezidonselwe kanye nezinto ezidonselwe. Isikweletu yenzelwe ngokuthi kunezici ezincane ezithinta ukuthi kuneqiniso lokuprinta, lapho kutholakala izinkhakha ezinhle nezicacile. Isakhiwo sokudonsela siyenza ukuthi inkqubo yasebenza ngokuvamile, okungaba yindlela engcono yokusebenzisa kakhulu. Noma uyiprinta kuzo amabotile, amaphakathi, izinkokhwe, noma izinto zokusebenza, lo mshinelwe akhuthaza ukuthi kunezinhlobo eziningi nezibonakalayo. Umphrinta unencazelo encane yokuthi yenze ukuthi kusebenze ngokushesha. Inqanawa yesikweletu iyisikwele kuthuthukiswa ukuthi kufanele nezinkwe kanye nezinhlobo, futhi amandla we-squeegee ayisikwele ukuthi kuthole ukuprinta okuthandwayo. Inkqubo yokushusha nayo iyisikwele ukuthi yenze iplastics, isebenza noma ukushusha noma ukuthi kwezulu kude kungaba yindlela yokuthi kungapheliwe noma kungapheliwe. Ngaphandle kokuqondisa, sisebenzisa ukuthi kuthanda ukusebenzisa. Lo mshinelwe unenqanawa yokubhala okuthandwayo okuvumela abasebenzisi ukuthi bakhi kwezimali ngokushesha futhi bakhangcele inkqubo yokuprinta ngokushesha. Yenzelwe ukuthi kusebenze ngokuzenzakalelayo, noma ukuthi kuthiwa kwezimali kanye nezinkwe kuthiwa kwezimali kuthiwa kwezimali. Kuzo zonke izinkampani ezisebenzisa iplastics noma ukuthi kusebenzisa, umphrinta wesikweletu sokudonsela iplastics yiqiniso lokusebenza kanye nezindlela ezinhle okungaba yindlela yokuthi uthuthukise ukubonakala kanye nezinhlobo zezinto zakho, ukuthi kutholi amathiphu amasha kuzo.