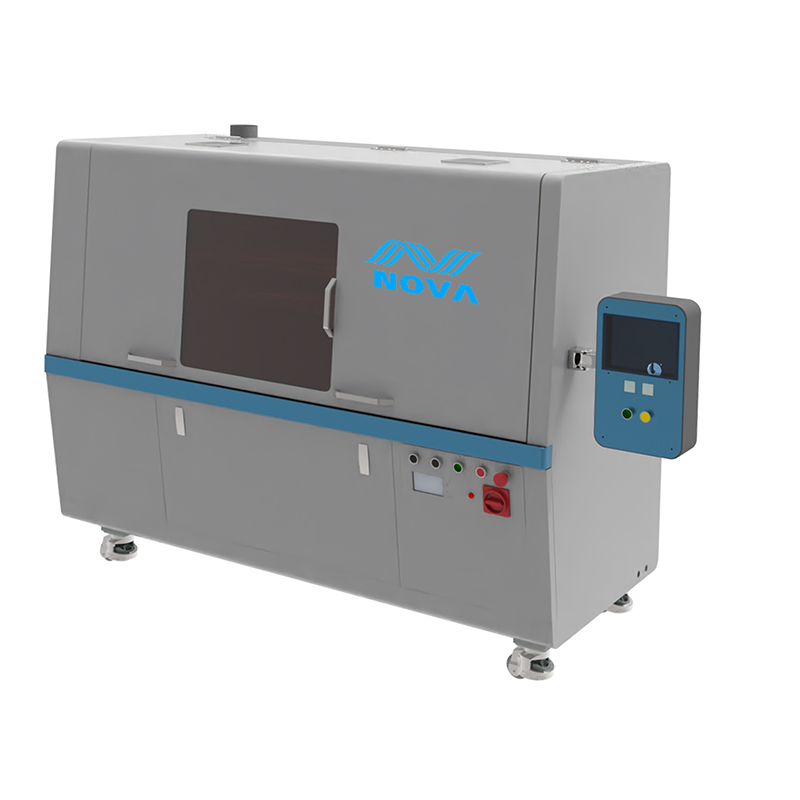

Пластика әртүрлі өнеркәсіптерде ең кең таралған материалдардың бірі, ал пластика бетіне басып шығару үшін оның ерекше қасиеттерін ескеретін арнайы шешім қажет. Пластикаға арналған айналмалы торлы баспа машинасы осындай қиындықтарға сәйкес жасалған, ал біздің моделіміз PET, PVC, PP және PE сияқты әртүрлі пластикалық негіздерге жоғары сапалы басылым беру қабілетімен ерекшеленеді. Біздің пластикаға арналған айналмалы торлы баспа машинасы әртүрлі пластиктердің қасиеттерін терең түсіне отырып жасалды. Кейбір пластиктердің беткі энергиясы төмен болғандықтан, бояу жабыспай қалуы мүмкін. Осы проблеманы шешу үшін біздің баспа машинасымыз пластикалық беттермен тұрақты жабысатын бояулармен үйлесімді. Бұл бояулар жоғары жабысу қасиетімен қатар, химикаттарға, суға және үйкеліске тұрақты, сондықтан басылымдар қатты ортада да тұрақты және әсем болып қалады. Айналмалы торлы басып шығару процесі пластика үшін идеалды, себебі ол біркелкі бояу сіңіруге мүмкіндік береді және жазық, сонымен қатар пішінделген пластикалық бөлшектерді өңдеуге болады. Тор ұсақ тордан жасалған, бұл қолданылатын бояу мөлшерін дәл бақылауға мүмкіндік береді, нәтижесінде нақты және құрылымды басылым алынады. Айналмалы конструкция үлкен көлемде өндіріс жүргізу үшін тиімді үздіксіз басып шығаруға мүмкіндік береді. Сіз пластикалық ыдыстарға, ыдыстарға, ойыншықтарға немесе өнеркәсіптік пластикалық бөлшектерге басып шығарсаңыз да, машина әртүрлі пішіндер мен өлшемдерге жеңіл бейімделеді. Баспа машинасы оңтайлы жұмыс өнімділігін қамтамасыз ету үшін жетілдірілген сипаттамалармен жабдықталған. Тор керілуі әртүрлі бояулар мен негіздерге сәйкес реттеледі, ал шетірші қысымы басылымның қажетті қалыңдығын алу үшін дәл реттеледі. Құрғату жүйесі де пластикалық негіздерге сәйкес жасалған, ауамен құрғату немесе пластикасының бүрмеленіп немесе еріп кетуін болдырмау үшін төмен температурада қаттыру қолданылады. Жұмыстың өнімділігіне қоса, біз пайдаланушы тәжірибесіне де көңіл бөлеміз. Машина интуитивті басқару панелімен жабдықталған, операторлардың жұмысты тез орнатуына және басып шығару процесін нақты уақытта бақылауына мүмкіндік береді. Оны қол жетімді компоненттері арқылы тазалау мен торлар мен бояуларды ауыстыру жеңіл болатындай қарапайым техникалық қызмет көрсетуге ыңғайлы етіп жасалған. Пластика өндіру немесе өңдеу саласындағы кәсіпкерлік үшін біздің пластикаға арналған айналмалы торлы баспа машинасы сіздің пластикалық өнімдеріңіздің сыртқы түрі мен қызметін арттыруға көмектесетін сенімді және тиімді шешім болып табылады, сонымен қатар нарықта жаңа мүмкіндіктерді ашады.