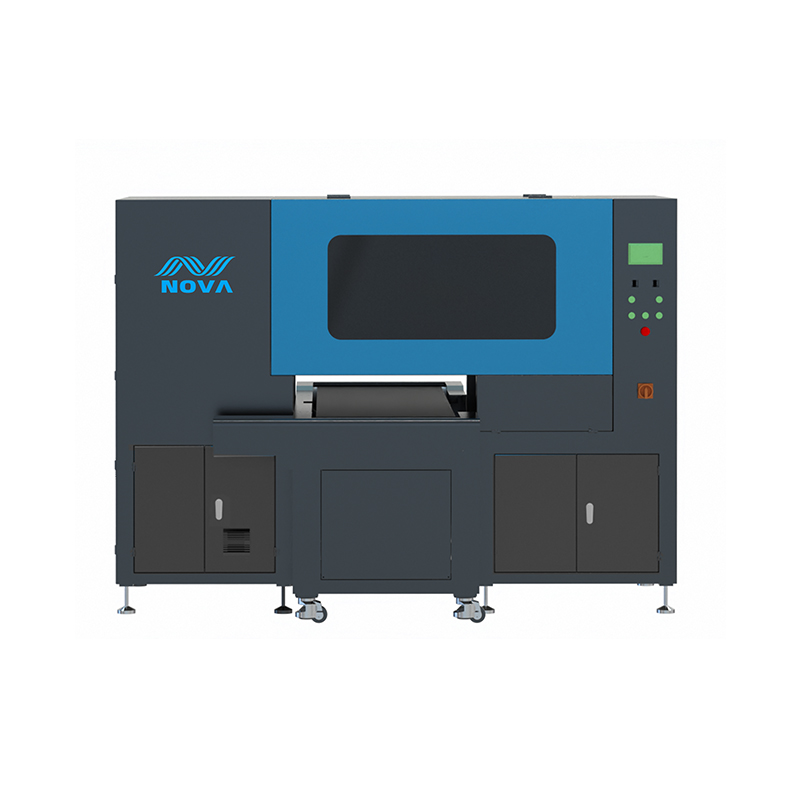

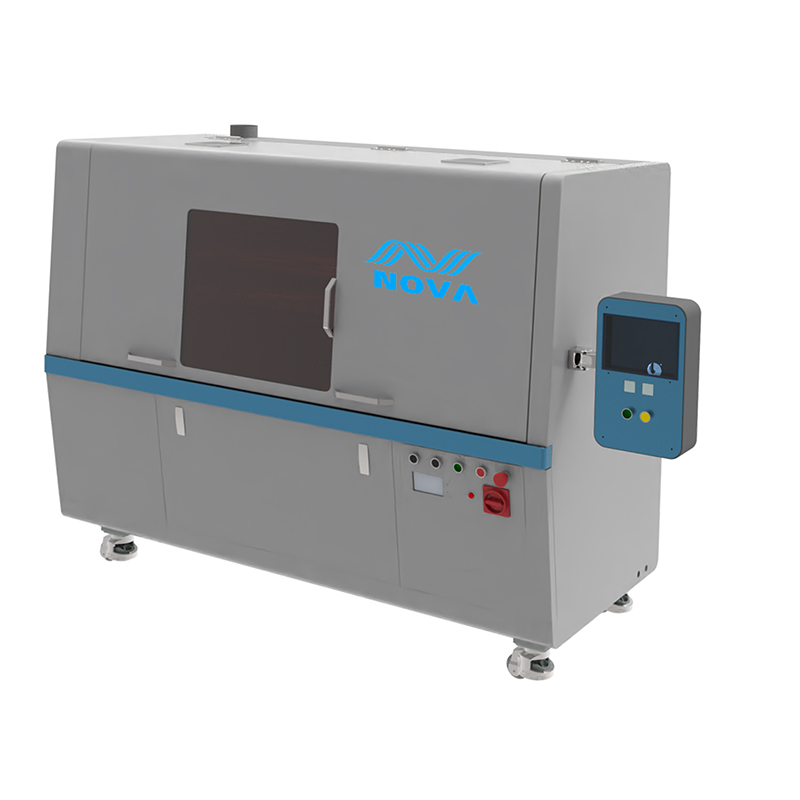

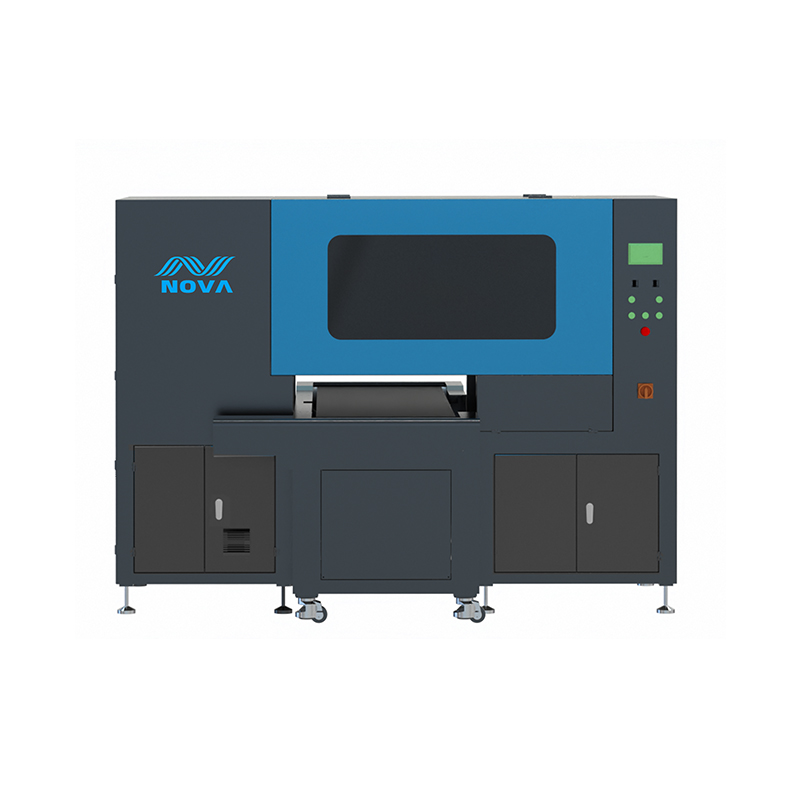

Premium Rotacijski Inkjet Precizni Stampac

Napredni rotacijski inkjet štampač kombinira izvrsno mehaničko inženjerstvo s najnovijom inkjet tehnologijom. To osigurava konstantnu i visoku kvalitetu štampanja s preciznošću i točnošću. Koristeći nozele s visokim razrješenjem, štampač točno postavlja kapljice tinte na papir za štampu, što rezultira oštrim slikama, tekstovima, detaljima i privlačnim bojama. Štapaljka ili opasa za štampu se neprestano okreće, pružajući stabilnu površinu za štampu. To osigurava da svaki jedan odštamp je bez naprjeđa i identičan ostalim. Bez obzira na koliko su detalji fini ili složeni, ovaj štampač održava izuzetnu točnost na svim dizajnima koje reprodukuje. Održava potrebnu profesionalnu kvalitetu štampe za razne primjene, uključujući reprodukcije umjetnosti i visokokvalitetne marketinške materijale.