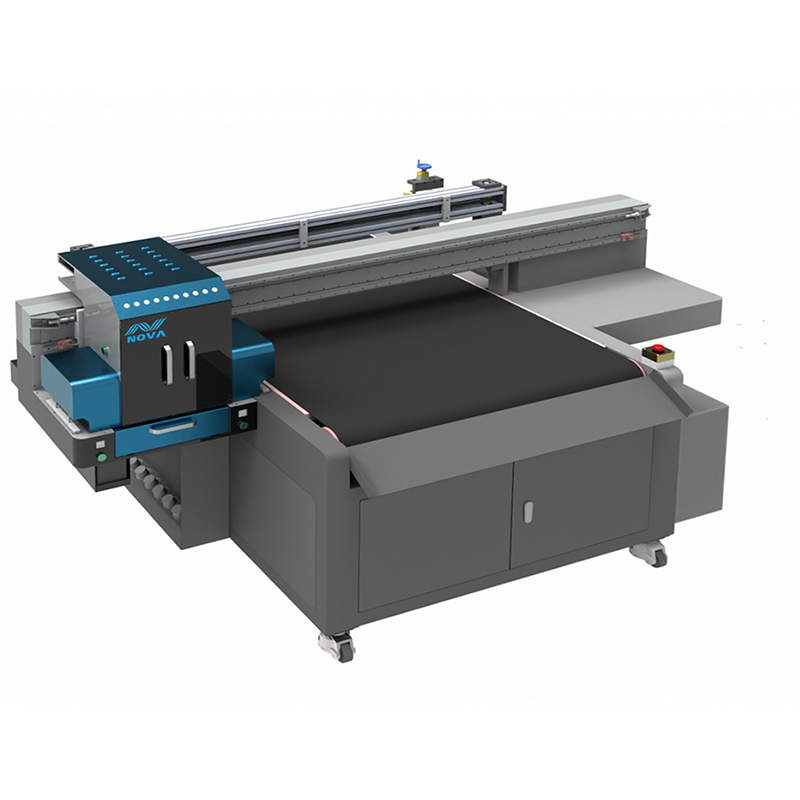

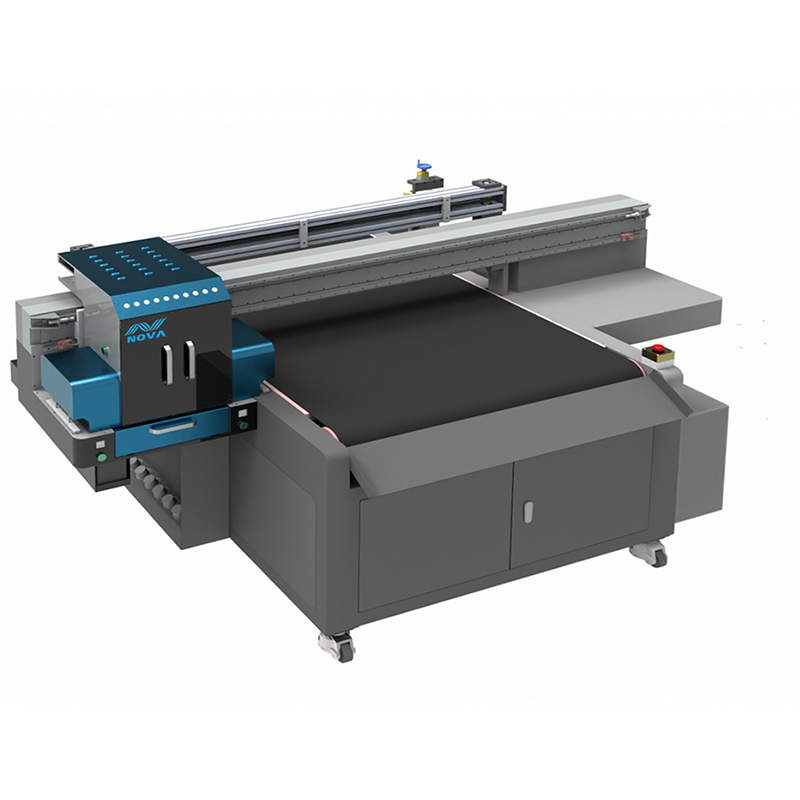

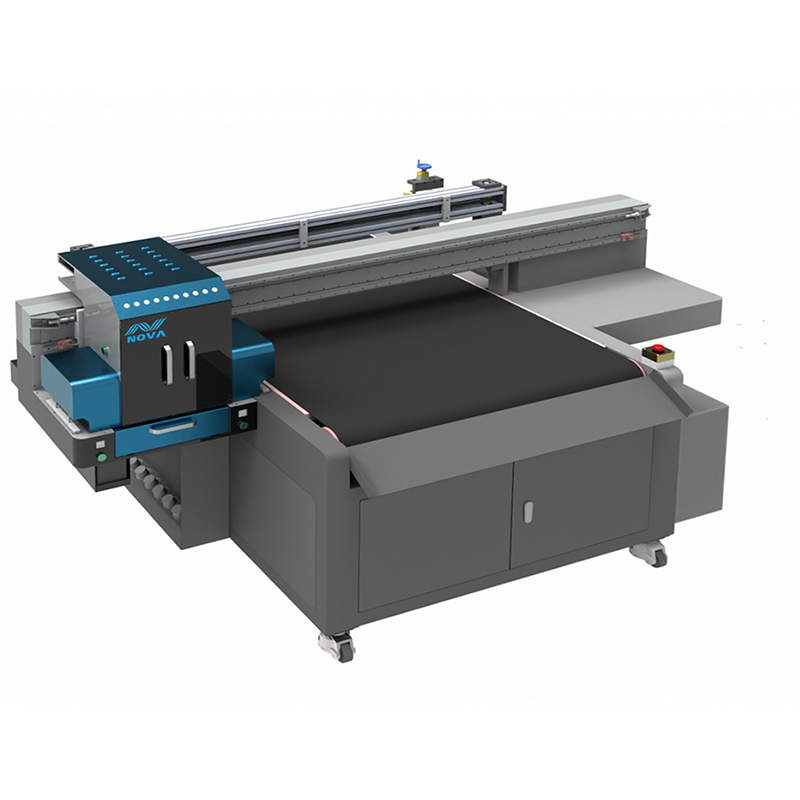

Wide Range of Supported Substrate Materials

UV Inkjet visual positioning printers are meant to process different types of substrates. Printers are capable of adjusting to surface texture and characteristics, be it paper, cardstock, or even more advanced materials such as plastic, metal, glass, or wood. The visual positioning system enables the printer to control the position of the ink in relation to where the substrate is placed, regardless of the shape and material attributes of the substrate. This flexibility makes it perfect for custom signage where acrylic and aluminum are frequently used, along with the manufacturing of personalized products throughout different materials. From individual projects to bulk production, this printer accommodates varying printing requirements.