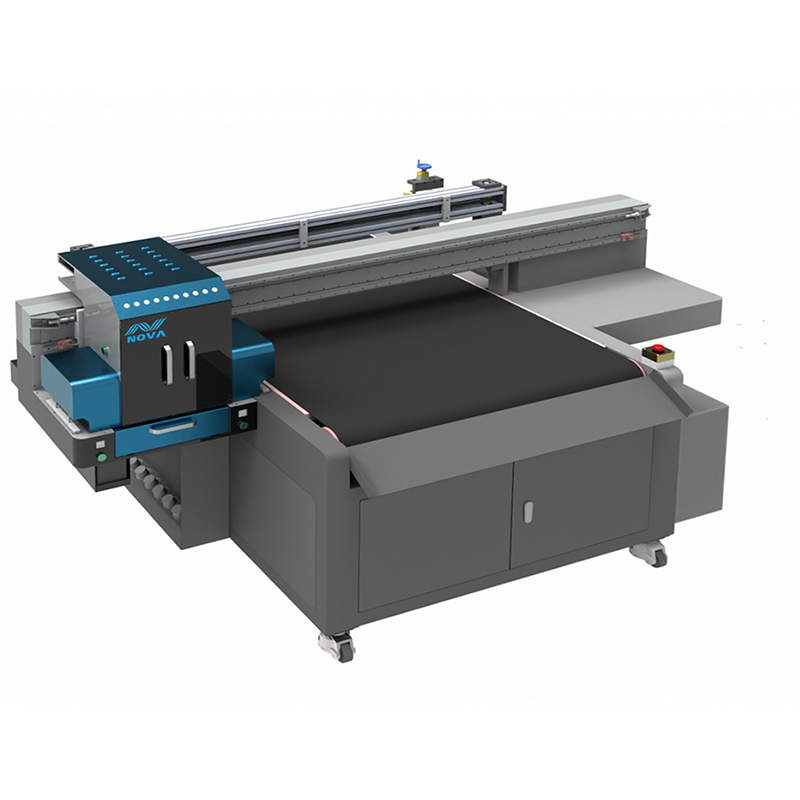

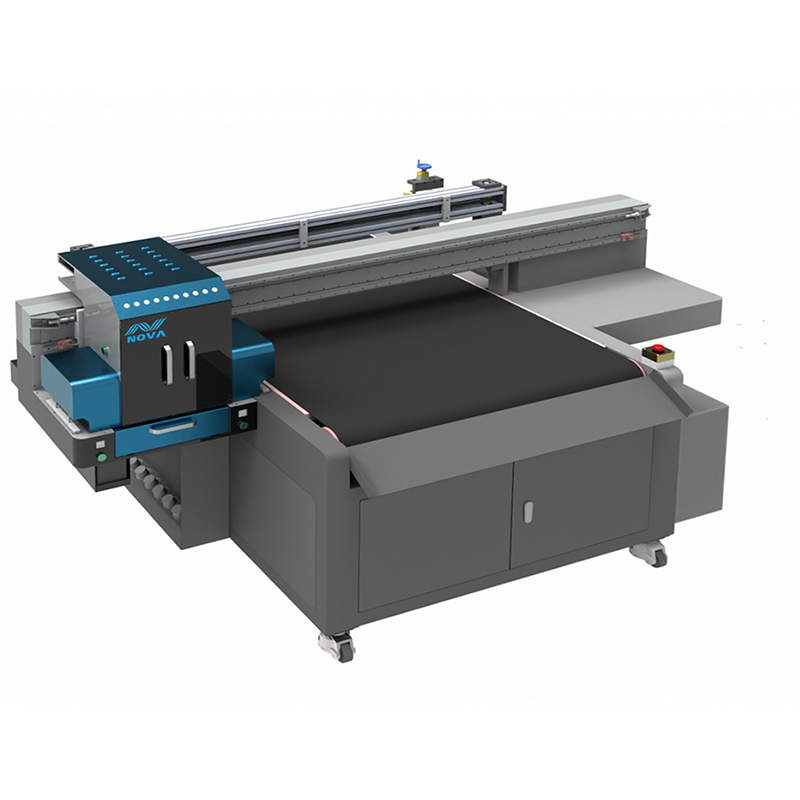

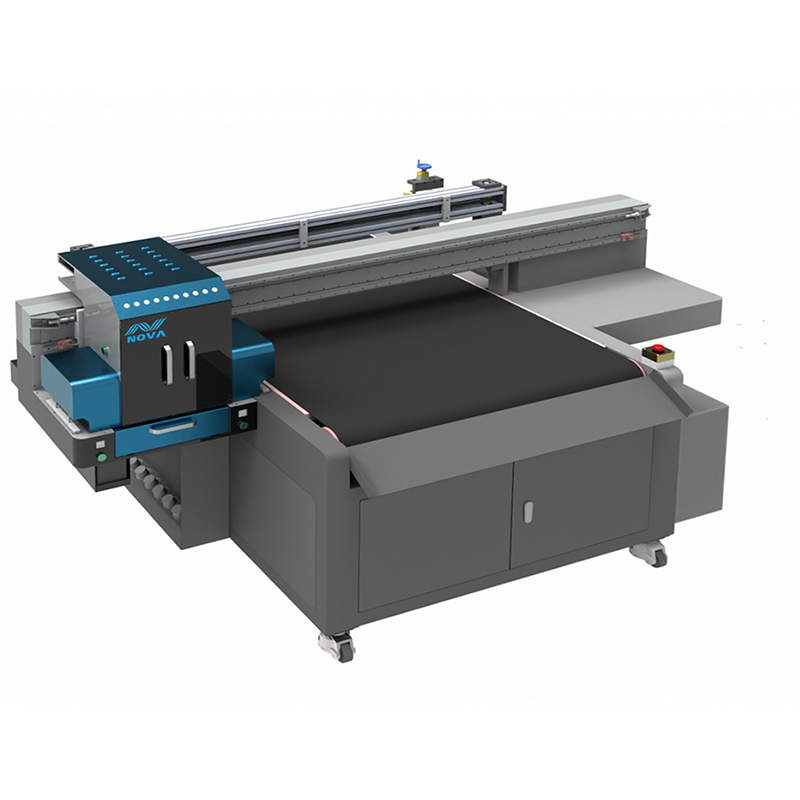

NOVA's high-speed visual positioning UV inkjet printer represents a significant leap forward in printing technology, designed to meet the demands of modern industries that require both speed and precision. This printer integrates state-of-the-art visual positioning systems with advanced UV inkjet technology, delivering prints that are not only fast but also of exceptional quality. The visual positioning system utilizes high-resolution cameras and sophisticated algorithms to accurately position each print, ensuring that even the most intricate designs are printed with pinpoint accuracy. This level of precision is crucial for industries such as packaging, where precise printing is essential for product identification and branding. The high-speed capability of our printer is achieved through its Single-Pass printing mechanism, which allows for rapid printing without sacrificing quality. This means that businesses can produce large quantities of printed products in a short amount of time, meeting the demands of high-volume production environments. The UV inkjet technology used in our printer provides additional benefits, such as instant curing of inks under UV light, resulting in prints that are resistant to fading, scratching, and chemical exposure. This durability ensures that printed products maintain their visual appeal over time, even in harsh environments. Furthermore, our printer's versatility allows it to print on a wide range of materials, including plastics, metals, and glass, making it suitable for various applications across different industries. Whether you're printing labels for packaging, promotional gifts, or industrial components, our high-speed visual positioning UV inkjet printer delivers consistent, high-quality results that meet your specific needs. With its combination of speed, precision, and durability, our printer is the ideal solution for businesses looking to enhance their printing capabilities and stay ahead of the competition.