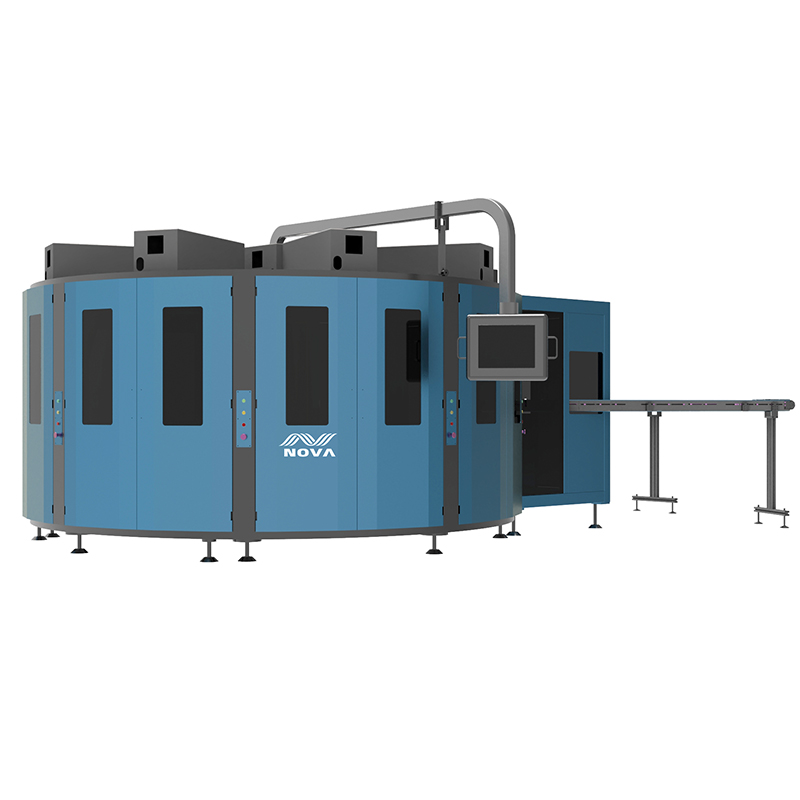

When it comes to printing on glasses, precision, efficiency, and quality are non-negotiable. The one pass rotary inkjet printer for glasses stands out as a game-changer in this specific application, and it embodies the innovative spirit that Xiamen Luhuajie Technology Equipment Co., Ltd. is known for. This printer is designed to meet the unique challenges of glass printing, where smooth surfaces, varying shapes, and the need for long-lasting, vibrant prints are key. One of the core advantages of this one pass rotary inkjet printer is its ability to complete the printing process in a single pass. Unlike traditional printers that may require multiple passes to achieve the desired result, this technology ensures that each glass item is printed efficiently, reducing production time significantly. For businesses in the manufacturing or promotional 礼品 sector, this means higher throughput, allowing them to meet tight deadlines and handle larger orders without compromising on quality. The rotary mechanism of the printer is another standout feature. It is engineered to handle the cylindrical or curved surfaces of glasses with remarkable stability. This ensures that the print is evenly distributed across the entire surface, avoiding smudges, misalignments, or uneven color application. Whether you are printing logos, intricate patterns, or detailed designs on drinking glasses, cosmetic glass containers, or decorative glassware, the rotary system adapts to the shape of the glass, guaranteeing consistent results every time. Integrating advanced inkjet technology, this printer delivers exceptional print quality. The inks used are specially formulated to adhere to glass surfaces, resisting scratches, water, and everyday wear and tear. This is crucial for glasses that are frequently used or exposed to various conditions, such as drinking glasses that go through washing or cosmetic glass containers that are handled regularly. The colors produced are vivid and true to life, ensuring that brand logos or decorative designs stand out and make a lasting impression. Moreover, the one pass rotary inkjet printer for glasses incorporates elements of the cutting-edge technology that Xiamen Luhuajie Technology Equipment Co., Ltd. prides itself on. It may include features like precise ink droplet control, which allows for sharp details even on small glass surfaces. The printer can also be customized to handle different sizes of glasses, from small shot glasses to larger tumblers, making it versatile for a range of applications. Whether you run a small business producing custom glassware for events or a large industrial facility manufacturing glass products in bulk, this printer can be tailored to your specific needs. Another benefit is the ease of operation. Despite its advanced technology, the printer is designed with user-friendliness in mind. It may come with intuitive control panels or software that allows operators to set up print jobs quickly, adjust parameters such as print size, color intensity, and design placement with precision. This reduces the learning curve for staff and minimizes the risk of errors, ensuring smooth production processes. In terms of adaptability, this printer is not limited to a single type of glass. It can handle various glass materials, including clear glass, frosted glass, and even colored glass, providing consistent results across different substrates. This flexibility is valuable for businesses that offer a diverse range of glass products, as they don’t need to invest in multiple printers for different glass types. For businesses concerned about sustainability, this printer also offers advantages. It uses ink efficiently, reducing waste compared to traditional printing methods. Additionally, the one pass process consumes less energy, contributing to a more environmentally friendly production cycle. Whether you are a small business looking to expand your custom glass printing capabilities or a large industrial manufacturer aiming to improve efficiency and quality, the one pass rotary inkjet printer for glasses is a solution that delivers on all fronts. It combines speed, precision, and durability to meet the unique demands of glass printing, ensuring that your products stand out in the market.