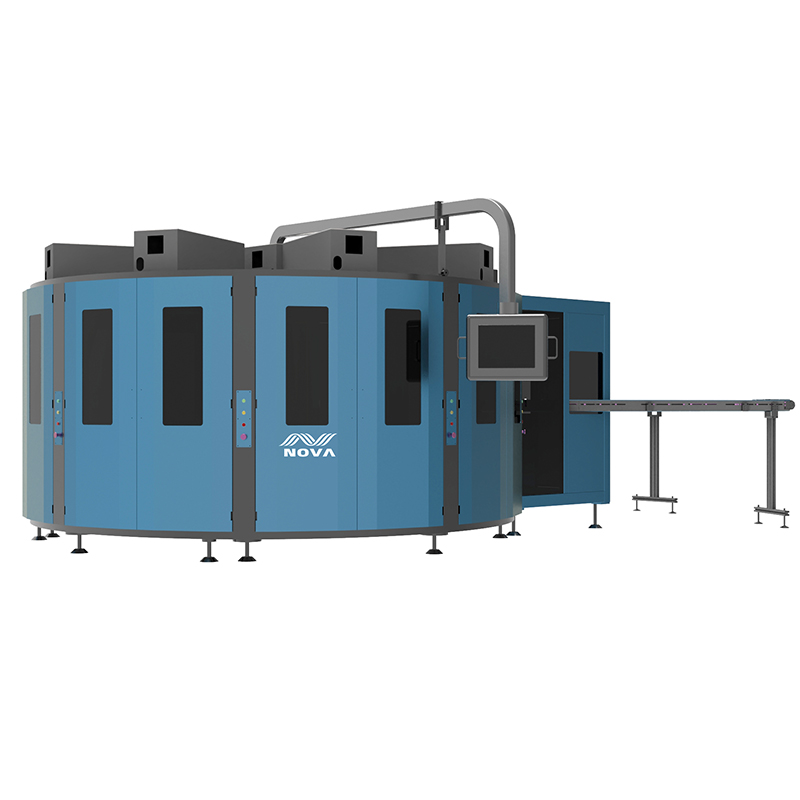

In the realm of printing, achieving rich, vibrant, and accurate colors is often a top priority, especially for products that need to stand out in the market. The one pass rotary 6 color inkjet printer is a powerful tool that meets this demand, offering a perfect blend of speed, color precision, and efficiency. Xiamen Luhuajie Technology Equipment Co., Ltd., as an innovator in printing solutions, leverages advanced technologies to develop such printers, catering to the diverse needs of various industries. The "6 color" feature of this printer is a key highlight. It typically uses a combination of cyan, magenta, yellow, black (CMYK) along with two additional colors, which can be light cyan and light magenta or other specialized colors depending on the application. This expanded color gamut allows for more accurate color reproduction, enabling the printer to handle a wider range of hues and shades. Whether it’s reproducing the subtle gradients of a brand logo, the vivid colors of a promotional image, or the intricate details of a decorative pattern, the 6 color system ensures that each color is rendered with exceptional accuracy and vibrancy, resulting in prints that are true to the original design. The "one pass" functionality is another major advantage. This means that the printer can apply all six colors in a single pass over the substrate, eliminating the need for multiple passes. This not only significantly reduces production time but also minimizes the risk of misalignment between colors. For businesses, this translates to higher productivity, as more items can be printed in a shorter period, and consistent quality, as each print is uniform and free from color shifts that can occur with multiple passes. This is particularly beneficial for high-volume production runs, where efficiency and consistency are critical. The rotary design of the printer adds to its versatility and efficiency. It is well-suited for printing on cylindrical, conical, or other curved substrates, such as bottles, tubes, cups, and containers. The rotary mechanism ensures that the substrate is held securely and rotated smoothly during the printing process, allowing the inkjet heads to apply the colors evenly across the entire surface. This makes the printer ideal for industries such as packaging, where many products have curved surfaces that require high-quality printing. Advanced inkjet technology is at the core of this printer’s performance. The inkjet heads are designed to deliver precise ink droplets, ensuring sharp details and smooth color transitions. The inks used are formulated to adhere well to a variety of substrates, including paper, plastic, metal, and glass, and they offer excellent durability, resistance to water, scratches, and fading. This ensures that the prints remain vibrant and intact even after prolonged use or exposure to harsh conditions, which is essential for products that need to maintain their appearance over time. Versatility is a defining characteristic of the one pass rotary 6 color inkjet printer. It can be used in a wide range of applications, from packaging printing for food and beverages, cosmetics, and household products to promotional items such as pens, keychains, and USB drives, and even industrial parts that require labeled or decorated surfaces. The ability to handle different substrates and produce high-quality, multi-color prints makes it a valuable asset for businesses in various sectors. User-friendliness is also considered in the design of this printer. It often comes with advanced software that allows for easy design upload, color calibration, and print job management. Operators can quickly set up the printer, adjust parameters such as print speed, ink density, and color balance, and monitor the printing process in real-time. This simplifies operation, reduces training time, and allows for quick changes between different print jobs, enhancing overall productivity. In terms of technology integration, the one pass rotary 6 color inkjet printer may incorporate elements of AI scanning or other advanced features, as part of Xiamen Luhuajie Technology Equipment Co., Ltd.’s commitment to innovation. These features can help optimize the printing process, such as automatically detecting substrate variations and adjusting ink application accordingly, further improving print quality and reducing waste. Whether you are a small business looking to expand your printing capabilities or a large manufacturer aiming to upgrade your production line, the one pass rotary 6 color inkjet printer offers a compelling solution. It combines the benefits of 6 color printing, one pass efficiency, and rotary versatility to deliver high-quality prints at a fast pace, helping businesses meet their production goals and stay competitive in the market.