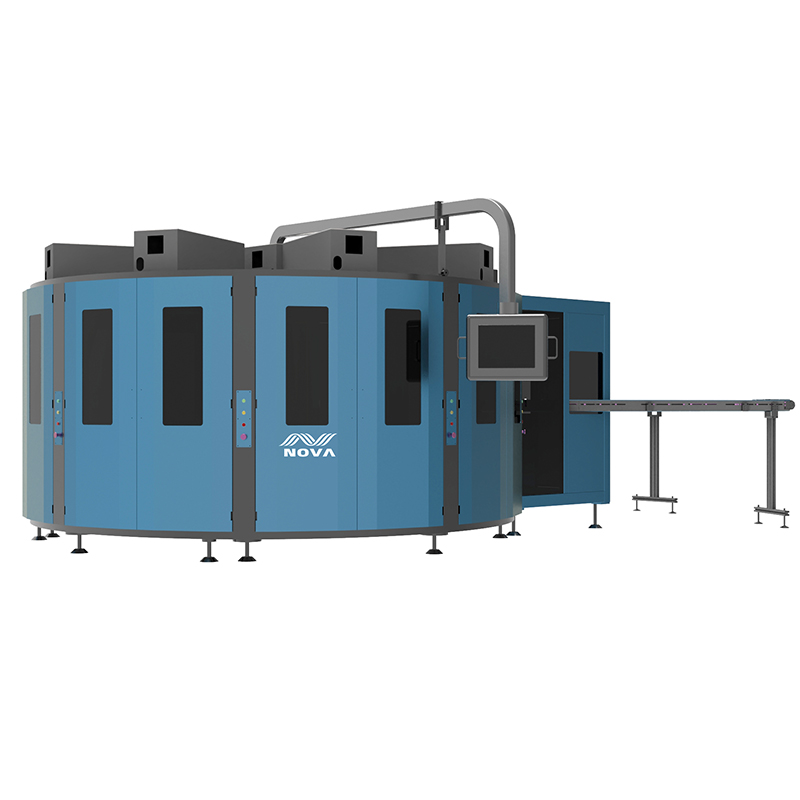

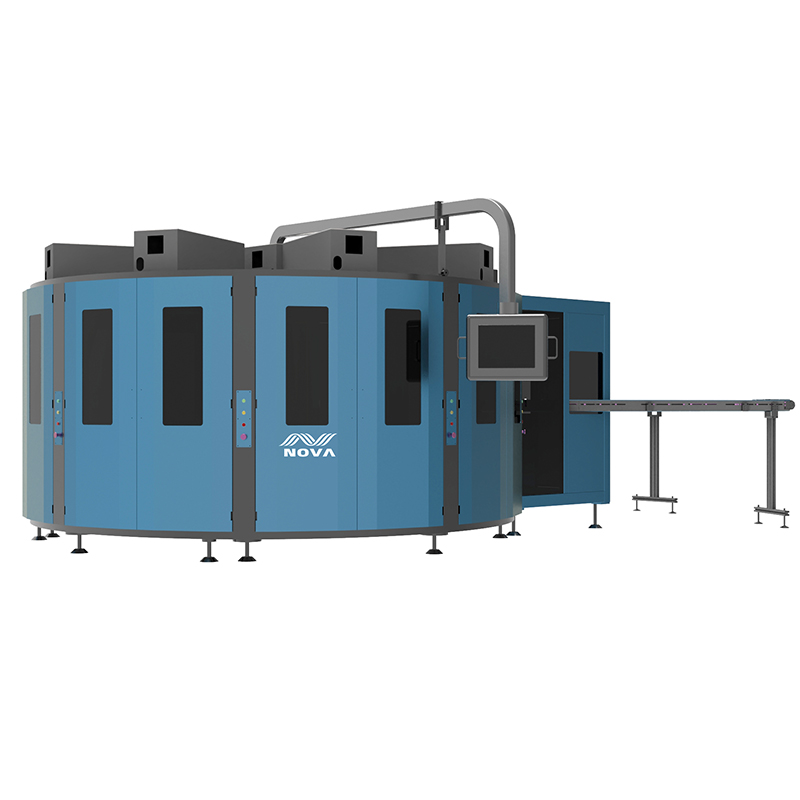

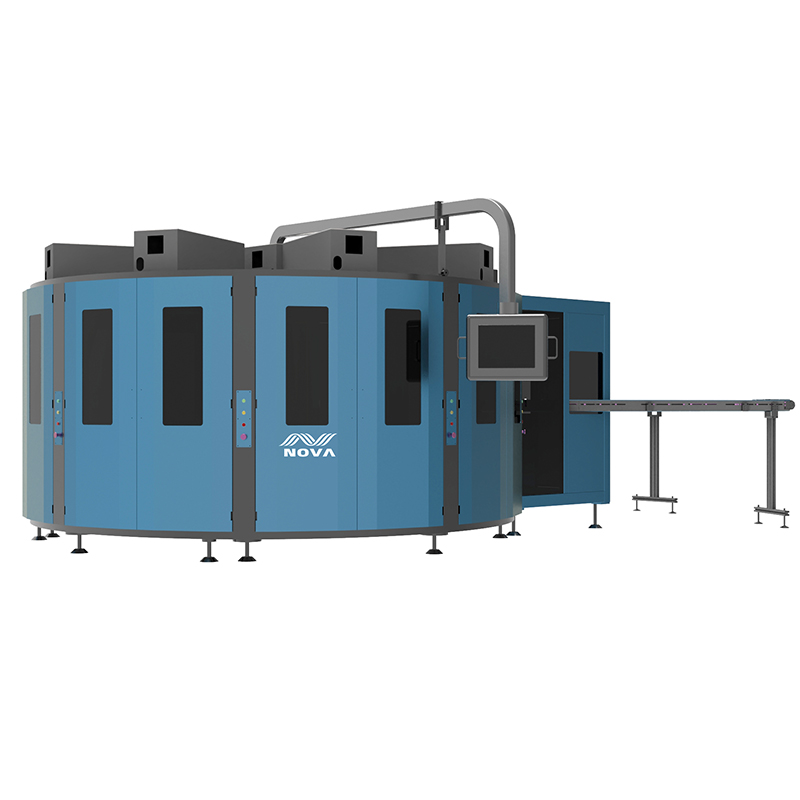

The one pass rotary inkjet printer for metals is a specialized piece of equipment developed by Xiamen Luhuajie Digital Technology Co., Ltd. to address the unique challenges of printing on metal surfaces. Metal printing requires a printer that can handle the hard, smooth surface of metals and ensure that the ink adheres properly, while also delivering high - quality and durable prints. This printer combines the advantages of one - pass and rotary inkjet technologies to achieve efficient and precise printing on metal parts. The one - pass technology allows for a single pass of the metal object under the printer to complete the printing process, significantly reducing production time compared to traditional printing methods. The rotary mechanism, on the other hand, ensures that cylindrical or curved metal parts, such as metal tubes, pipes, or rods, are printed evenly and accurately. The printer uses specially formulated inks that are designed to bond with metal surfaces. These inks are resistant to corrosion, heat, and abrasion, making them suitable for metal parts that are used in harsh environments, such as automotive components, industrial machinery, and construction materials. The high - resolution printing capability of this one pass rotary inkjet printer for metals ensures that even the smallest details, such as serial numbers, logos, or complex patterns, are printed clearly and legibly. It also features advanced control systems that allow for easy adjustment of printing parameters, such as ink density and print speed, to meet the specific requirements of different metal printing applications. For manufacturers in the metalworking industry looking to enhance their product identification and branding, this printer is an excellent investment.