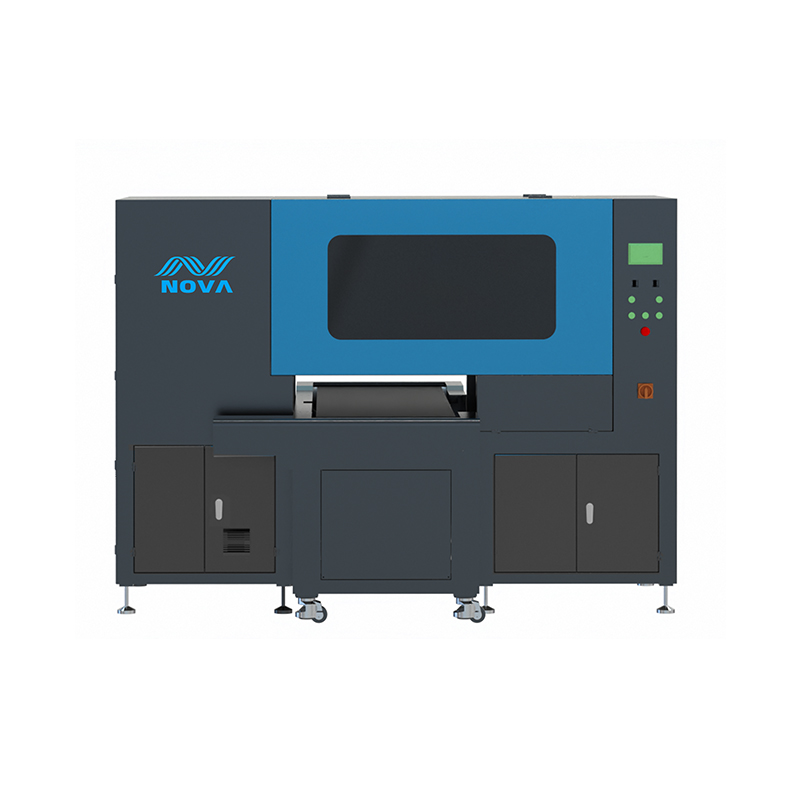

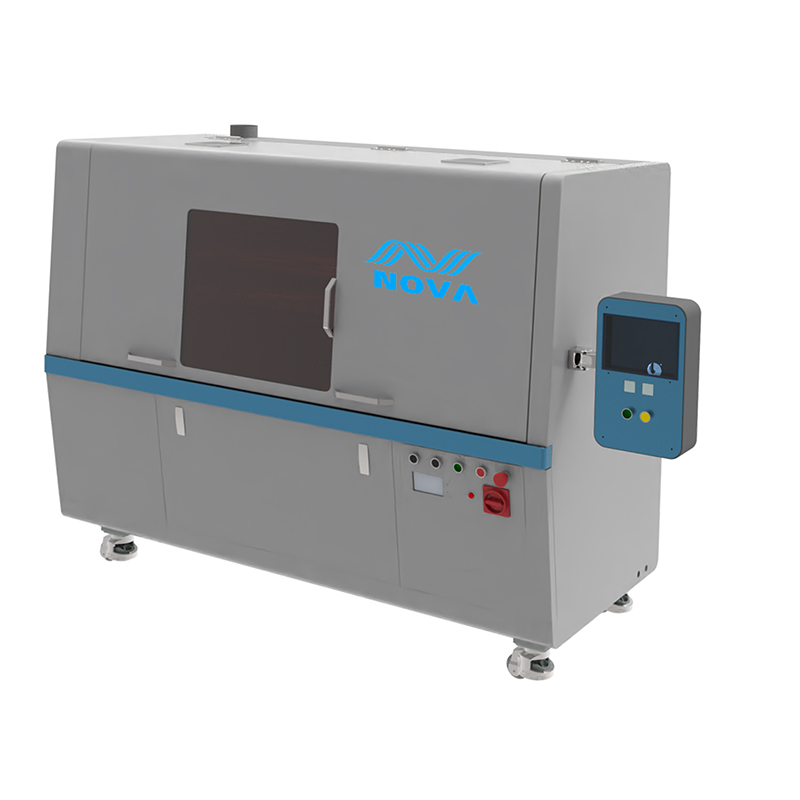

Teastaíonn priontálaí a bheidh in ann na hairíonna a bhaineann le haghaidh priontála ar phlastaigí, cosúil le haghaidh éineas reatha, téacsanna éagsúla, agus an t-áit a bheidh ag teastáil as priontéil faoi ghairdín, agus tá ár priontálaí inkjet rothlach againn do phlastaigí deartha go sonrach chun sin a dhéanamh. Cuireann an priontálaí seo le chéile na breisnúcháin a bhaineann le haghaidh oibríochtaí rothlacha le teicneolaíocht inkjet chun priontéil ardchaighdeána, faoi ghairdín a choinneáil ar roinnt mhaith cineálacha éagsúla plastaigh, ag déanamh de chuid riachtanach do ghnóthais sa tionscal pacaíochta, umhacht, leictreonachas, agus táirgí chun ceannach. Úsáideann ár priontálaí inkjet rothlach do phlastaigí duillinn speisialta a bhfuil cruthaithe chun a bheith buailte go láidir ar dhromchlaí plastaigh. Tá na duillinn seo ina gcoinneamh uisce, ceimiceál, solas UV, agus caillteanas, ag deimhniú go mbeidh na priontéil ag fanacht beo agus léite, fiú tar éis úsáide nó nochtú do choinníollacha trom. Cibé an bhfuil tú ag priontáil ar phlastaigí daite cosúil le PVC nó ABS, nó plastaigí shnasta cosúil le PE nó PP, bíonn an t-ink ag ceangal go héifeachtach, ag baint báis as samplaí cosúil le haghaidh bhuailt, mealltacht, nó smúdú. Ligeann an dearadh rothlach an phriontálaí priontáil leanúnach, a bhfuil an-éifeachtach do tháirgeadh i meascán mór. Is féidir leis rian agus páirtí plastaigh corrtha a láimhseáil, agus míreanna solathracha cosúil le haghaidh plastaigh