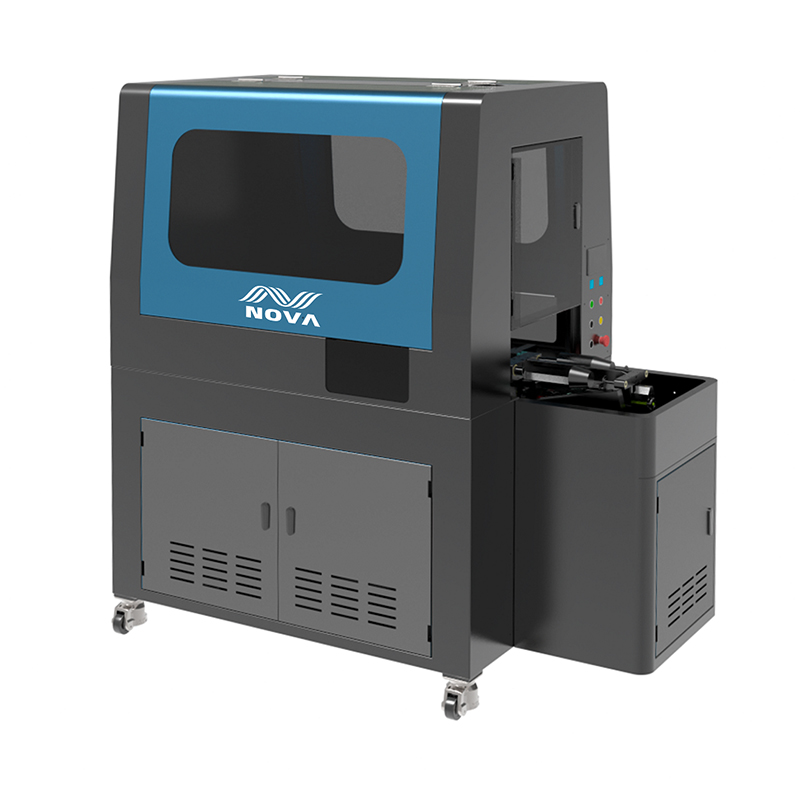

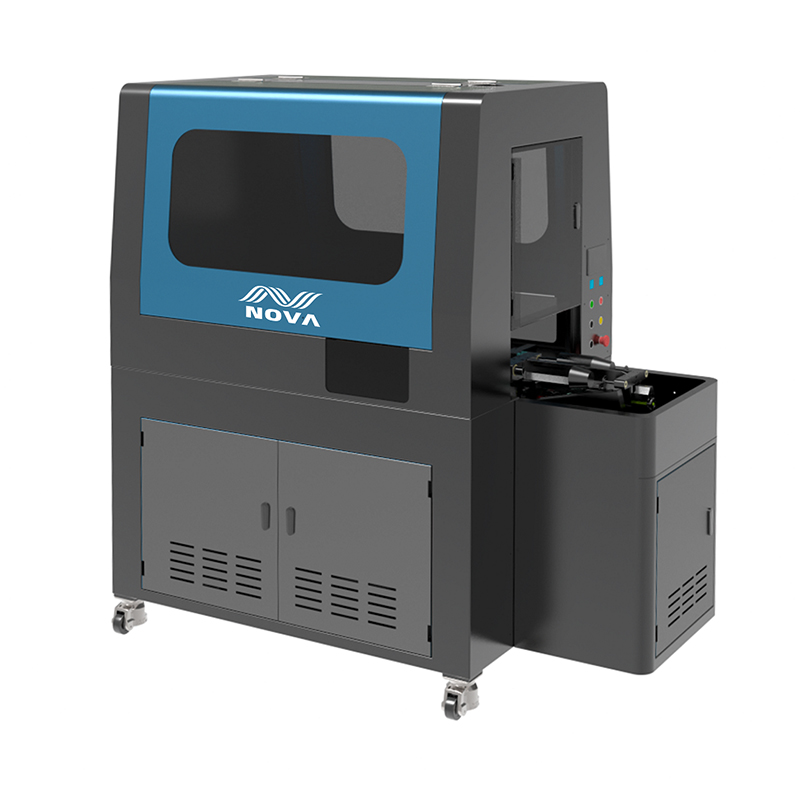

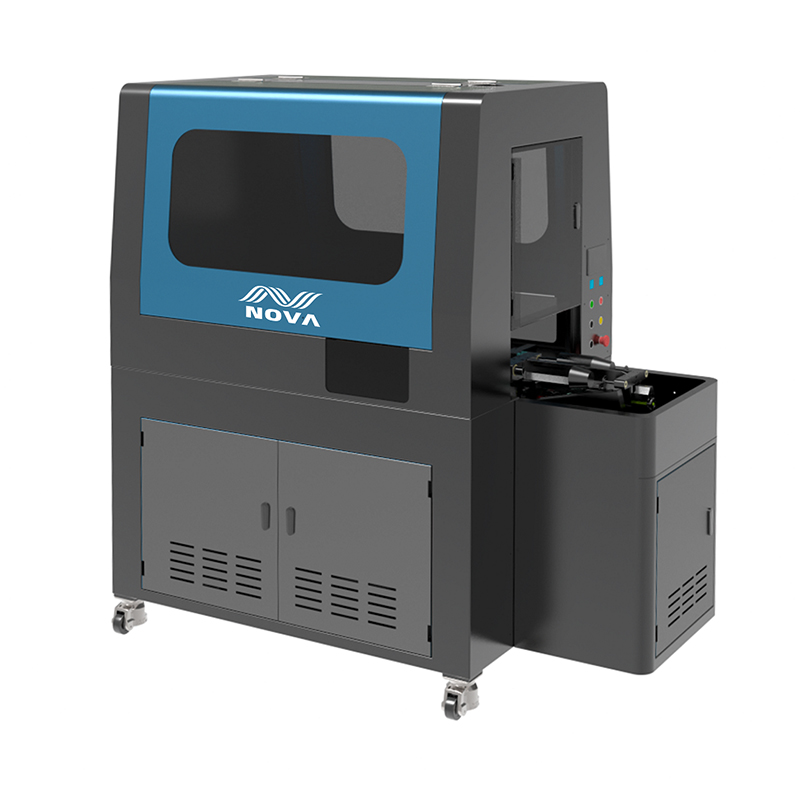

دقت در چاپ بطری امری اساسی است و چاپگر جوهرافشان دقیق بطری شرکت Xiamen Luhua Jie Digital Technology Co., Ltd. استاندارد دقت را در صنعت تعیین میکند. چاپگرهای جوهرافشان دقیق بطری ما با ترکیب فناوری اسکن هوشمند مصنوعی (AI) و چاپ جوهرافشان تکپاس، به سطح خیرهکنندهای از دقت دست پیدا کردهاند که حتی متون کوچک، لوگوهای پیچیده و الگوهای ظریف را با وضوح فوقالعادهای بازتولید میکنند. این سطح از دقت برای صنایعی مانند داروسازی حیاتی است؛ زیرا نیازمندیهای آزمایشگاهی نظیر چاپ دقیق اطلاعات دوز دارویی و شمارههای لات در بطریها الزامی است و همچنین برای کالاهای لوکس که برنامهریزی بدون عیب ضروری است. این چاپگرها از سنسورهای پیشرفتهای برای تشخیص موقعیت دقیق بطری استفاده میکنند و پارامترهای چاپ را بهصورت لحظهای تنظیم میکنند تا در قبال تغییرات جزئی در تراز یا شکل بطری جبران انجام دهند. این موضوع تضمین میکند که هر چاپ بهطور کامل ثبت شود، بدون اینکه خطایی مانند محوشدگی، تاری یا عدم تراز وجود داشته باشد. قابلیتهای چاپ با رزولوشن بالا تا 1200 dpi اجازه میدهد متون تیز و گرافیکهای پررنگی حتی روی سطوح منحنی یا غیرمنظم بطری ایجاد شود. چاپگرهای جوهرافشان دقیق بطری ما همچنین برای کار با انواع مواد بطری از جمله شیشه، پلاستیک و فلز طراحی شدهاند و از جوهرهای تخصصی استفاده میکنند که بهخوبی چسبیده و دقت خود را در طول زمان حفظ میکنند. چه برای پروژههای سفارشی کوچک یا تولید انبوه، این چاپگرها نتایجی یکنواخت و دقیق ارائه میدهند و به کسبوکارها کمک میکنند تا بالاترین استانداردهای کیفیت را حفظ کنند و نیازهای سفت و سخت صنعتی را برآورده سازند.