Key Differences Between Bottle and Tumbler Inkjet Printers

Print Surface Compatibility

Inkjet printers designed for bottles and tumblers handle different surfaces pretty well, from glass to plastic and all sorts of coatings too. Bottle printers really shine when dealing with those tricky curved surfaces because they're built to print on things like glass containers or PET plastic bottles that we see everywhere in drinks packaging. Tumbler printers meanwhile tend to be the go to choice for smoother surfaces, especially metals and shiny finishes found on coffee mugs and other promotional products people love to collect. The Journal of Imaging Science did some research showing how much difference material makes for ink sticking properly and getting good quality prints. So picking the right printer matters a lot depending on what kind of surface needs printing.

Surface texture really affects how well ink sticks to materials. Generally speaking, smoother surfaces tend to hold ink better than rough ones, which can actually make prints look fuzzy and wear off faster over time. Most manufacturers will list what kinds of materials work best with their products. Some printing systems come equipped with special features or require certain treatments before applying ink to get good results. For anyone serious about getting long lasting, vibrant prints on various substrates, understanding these surface interactions becomes pretty important in the selection process.

Application-Specific Design Features

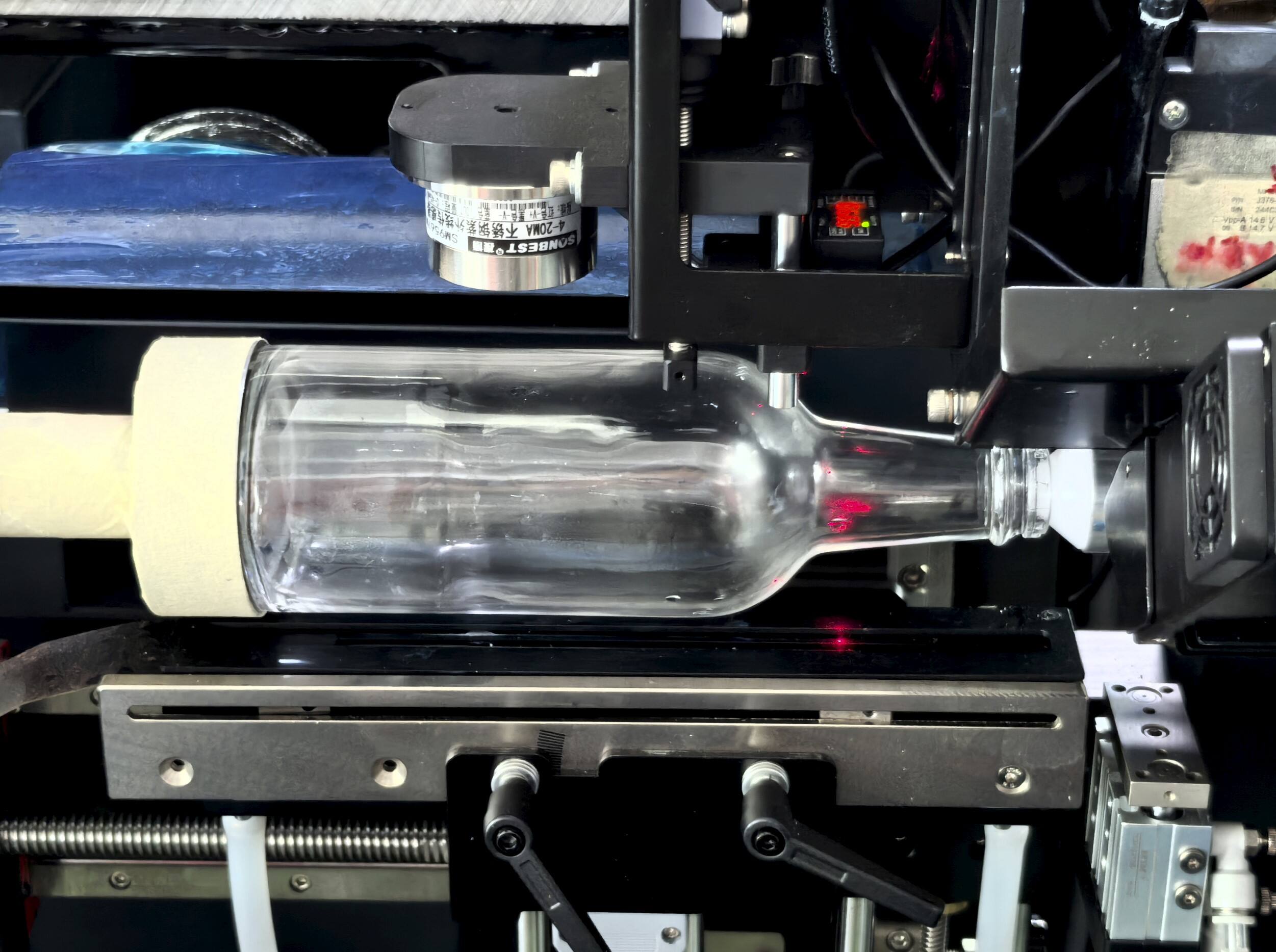

The structural design of bottle and tumbler inkjet printers differs significantly based on what they need to accomplish. One key difference lies in how the nozzles are arranged these arrangements change depending on what kind of surface needs printing and what materials are involved. Take bottle printers for example many top models come equipped with multiple nozzles that enable full circle printing around bottles. This makes them perfect for drinks companies needing brand logos all the way around cans or glass containers. On the other hand, when it comes to printing on custom bags, the focus shifts toward flexibility. These machines handle different patterns and color combinations really well, something that matters a lot during events where promotional materials need quick turnaround times and eye catching designs.

How these printers are built really matters when it comes to what they can do across different sectors. Industry insiders point out that one big thing separating them is how well they handle varying production needs, from running fast to handling complex designs. Take John Doe for instance, who works extensively with industrial printing tech. He puts it this way: "When machines offer diverse design options, companies get much better at adjusting their output according to what customers want right now." The way these printers are constructed basically determines where they fit in the market and how effectively they perform day to day.

Ink Adhesion Mechanisms

When it comes to how ink sticks to surfaces during inkjet printing, there's actually a mix of chemistry and physics at work, and this varies quite a bit depending on whether we're talking about bottles versus tumblers. Different types of inks are formulated specifically for various materials, so they stick better and last longer after printing. Bottle printers generally go for UV inks because these work really well on things like plastic bottles made from PET or glass containers. For tumblers though, manufacturers often add special chemicals to the ink formula that help it grab onto metal surfaces more effectively. There's another aspect too many people don't think about: before applying the ink, some surfaces need pre-treatment processes such as corona treatment or even flame treatment. These methods basically clean and activate the surface so the ink has something solid to cling to when printed.

When it comes to how long printed designs stay looking good, experience shows that smooth surfaces tend to hold up much better. Take custom inkjet printers for paper bags as an example the ink actually bonds better to these surfaces which means the colors don't fade as quickly. Anyone who has dealt with printed packaging knows that maintaining consistent quality matters a lot, particularly when products get exposed to different conditions during shipping and storage. Industry numbers back this up too, with reports showing around 30 percent improvement in print lifespan on properly treated materials. This makes sense when we think about matching the right inks to specific substrates something manufacturers need to pay close attention to if they want their printed products to maintain their appearance throughout their entire lifecycle.

Specialized Applications for Different Printers

Inkjet Printer for Fabric Bags and Promotional Items

Inkjet printers bring something special to fabric bag production when it comes to customization options. These machines produce really sharp, colorful prints that work great for things like company giveaways or event merchandise. As people start wanting their stuff to look different from everyone else's, businesses have found they can put custom designs right onto fabric bags, which satisfies customer cravings for one-of-a kind items. What makes this even better is that most modern inkjet systems actually go easy on the environment too. They tend to use water based inks rather than harsh chemicals, so there's less impact on Mother Earth. Looking ahead, we're seeing a real uptick in interest across the promotional products sector for these kinds of fabric items made with inkjet tech. More brands are starting to see how valuable it is to offer both personalized touches and greener alternatives at the same time.

High-Quality Bottle Printing Solutions

The introduction of bottle inkjet printers has completely changed things for many industries, especially those in food and drinks. What makes these printers so good is their ability to produce really clear prints with colors that pop right off the glass. Craft brewers and small-scale drink makers love them because they can put detailed logos and eye-catching designs directly onto bottles without breaking the bank. Take local breweries for instance they've seen amazing results after switching to better printing tech. Their customers notice the difference immediately, which means more people remember their brands and actually want to buy again. For businesses looking to stand out on store shelves, getting quality bottle printing isn't just nice to have anymore it's becoming essential for staying competitive in today's market.

Custom Bags and Paper Bag Printing Requirements

When it comes to printing on those custom and regular paper bags, there are a few key things businesses need to think about first. Choosing the correct ink type matters a lot, along with how fast those inks dry without smudging. The good news is inkjet printers made specifically for paper bags do pretty well at keeping prints vibrant while still drying quickly enough not to ruin everything. With more people getting concerned about what happens to our planet, companies now have to follow certain environmental rules regarding both the inks they use and the actual bag materials. That's why we're seeing lots of manufacturers switch over to greener alternatives lately. They want to catch up with what shoppers are asking for these days. Most customers actually seem to favor bags that look good but also happen to be better for the environment too. People appreciate being able to personalize something while knowing it won't hurt Mother Earth either.

Technical Considerations for Optimal Performance

Print Resolution and Color Management

When it comes to printing on shopping bags or bottles with inkjet technology, getting the right print resolution makes all the difference in how good the final product looks. Most applications work well between 300 and 1200 DPI, though some specialized jobs might need even higher settings. Sharp details and rich colors depend heavily on this setting. Color management matters too. Things like ICC profiles and regular calibration help keep colors looking the same whether they're printed on plastic, paper or fabric surfaces. Print shops that pay attention to these details see better results when clients want logos or promotional designs that stand out. Consistent quality isn't just about aesthetics either it directly impacts brand recognition and customer perception.

Throughput Speed Comparison

Looking at how fast they work, bottle printers generally outperform tumbler printers because of things like continuous ink jet (CIJ) systems and those super fast print heads we've been seeing lately. The cool part? These tech upgrades actually make printing faster while still keeping good quality prints, something businesses really need when they're trying to meet their production goals. But there are some other things that matter too. For instance, how long it takes for the ink to dry and whether the printer works well with different materials can seriously impact how much gets done in a day. Companies using custom bag inkjet printers report getting way more done in busy facilities. They find themselves spending less time waiting around for machines to catch up and more time making money from all that extra output.

Substrate Pre-Treatment Needs

Getting good prints from inkjet machines when working with paper bags or fabric products really depends on how we prepare the material surfaces first. When we treat things like paper and cotton fabrics properly, the ink sticks better and doesn't run or fade after printing. There are several methods available too. Some shops use corona treatment which basically charges up the surface so ink grabs onto it better. Others might apply special primers to rougher materials where regular ink just won't hold. Looking at what actual businesses have done shows pretty clearly that taking time for proper surface prep makes a big difference. Prints last longer, colors stay vibrant, and overall quality improves significantly. Paying attention to these details not only gets better output but also means less wear and tear on the actual printing machinery over time.

Cost and Durability Factors

Initial Investment vs Long-Term Maintenance

Thinking about buying bottle or tumbler inkjet printers? Don't forget to look at both what it costs upfront and what happens with maintenance down the road. Bottle printers generally come with a bigger price tag because they have advanced tech that lets them print directly onto round surfaces without any issues. Tumbler models tend to cost less when first purchased, but watch out for those ongoing expenses related to replacement parts and supplies. According to industry reports, maintenance bills really fluctuate from one business to another. Most experts recommend getting these machines serviced roughly every half year to keep things running smoothly. Machines typically break down somewhere around once every 18 months give or take, though this depends heavily on how much they get used day to day.

UV Ink vs Dye-Sublimation Consumables

When choosing a printer, knowing what sets UV ink apart from dye-sublimation materials really matters. Take those UV inks used in top notch bottle printing systems – they get set almost immediately with UV light exposure. That makes them great for jobs needing fast results and lasting prints. We see these producing bright colors that stick around on all sorts of surfaces like plastic bottles and metal cans. On the flip side, dye-sublimation works better with fabric products such as tote bags. The ink turns into gas when heated and actually bonds with the fabric itself, creating those smooth color transitions and fine details we love. Sure, UV inks cost a bit more upfront, but most businesses find they last longer and work well across different printing needs. Looking at current market shifts, more companies are switching to UV technology because it adapts to various tasks while generating less waste than older printing approaches.

Machine Lifespan in Industrial Environments

The actual lifespan of bottle and tumbler inkjet printers in factories varies quite a bit depending on how they're used and maintained. Most factory managers know from experience that keeping these printers well maintained really adds years to their useful life. Some models last way past five years even when running nonstop through tough production cycles. When printers get constant action in busy facilities though, parts start wearing down faster. That means technicians need to check them more often just to keep everything working right. The better built industrial grade printers generally last longer because they're constructed with heavier duty materials and components that stand up to daily abuse. These machines usually perform reliably throughout their lifetime too, something plant engineers notice during routine inspections. Regular cleaning, replacing worn parts before they fail, and following manufacturer guidelines for maintenance makes all the difference between getting good value from equipment investments versus dealing with expensive breakdowns down the road.

Table of Contents

-

Key Differences Between Bottle and Tumbler Inkjet Printers

- Print Surface Compatibility

- Application-Specific Design Features

- Ink Adhesion Mechanisms

- Specialized Applications for Different Printers

- Inkjet Printer for Fabric Bags and Promotional Items

- High-Quality Bottle Printing Solutions

- Custom Bags and Paper Bag Printing Requirements

- Technical Considerations for Optimal Performance

- Print Resolution and Color Management

- Throughput Speed Comparison

- Substrate Pre-Treatment Needs

- Cost and Durability Factors

- Initial Investment vs Long-Term Maintenance

- UV Ink vs Dye-Sublimation Consumables

- Machine Lifespan in Industrial Environments