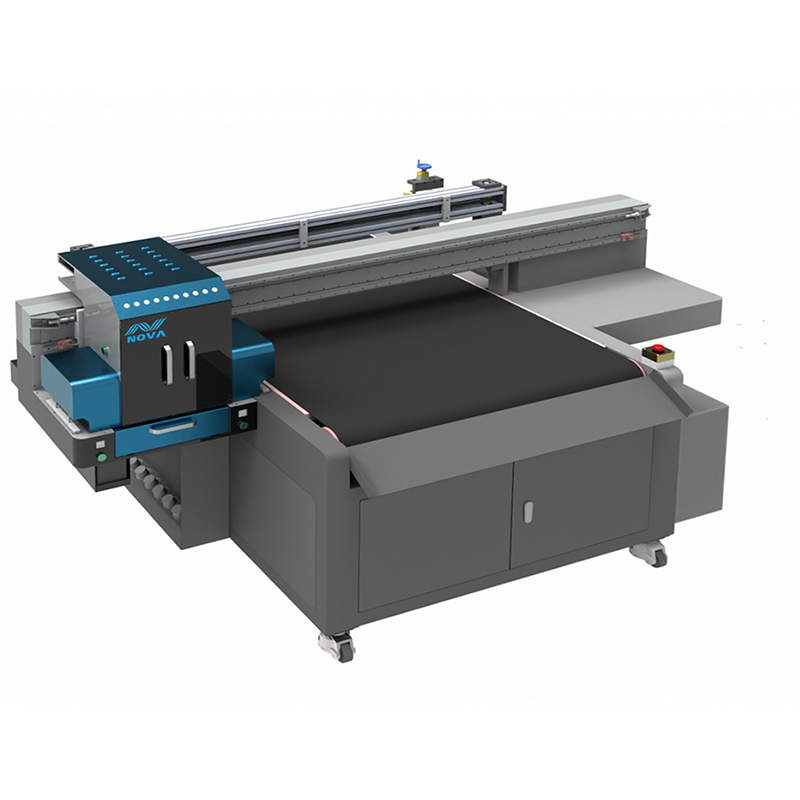

Enhanced Efficiency with Rapid Curing Using UV Technology

These printers improve production efficiency by integrating visualization with UV curing technology. Unlike traditional air drying inkjet printers, UV inkjet printers cure ink using ultraviolet light. This means that prints are instantly dry and ready for picking up right after printing, which saves time spent on drying and increases job completion speed. The quick curing time allows for application of thicker ink layers too, which makes prints more vibrant and high – density. Businesses do not need to wait for ink to dry before different print runs can be conducted, allowing them to increase output, manage high – volume orders, and overall improve productivity.