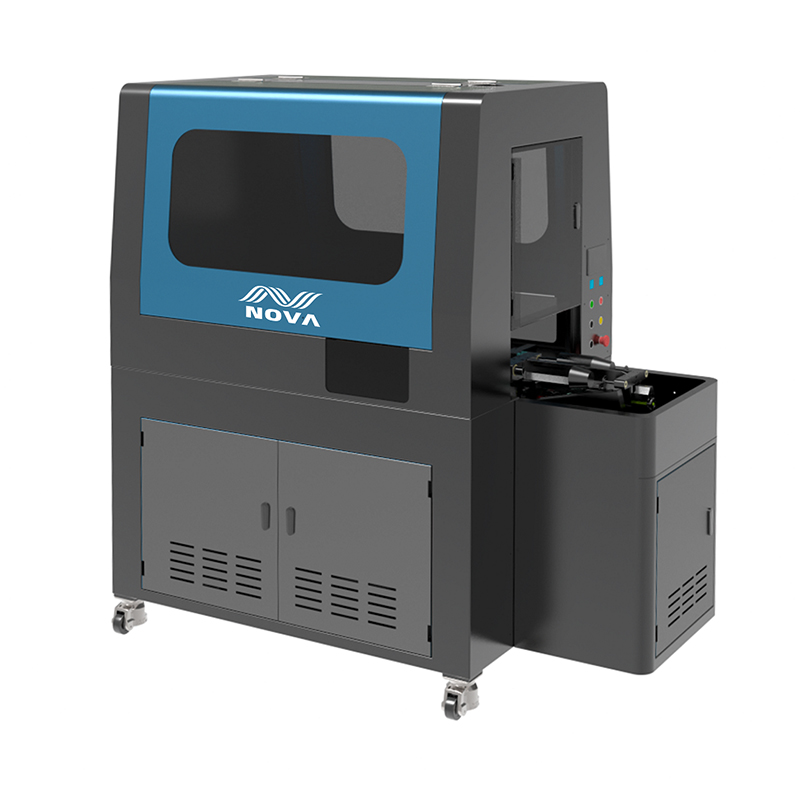

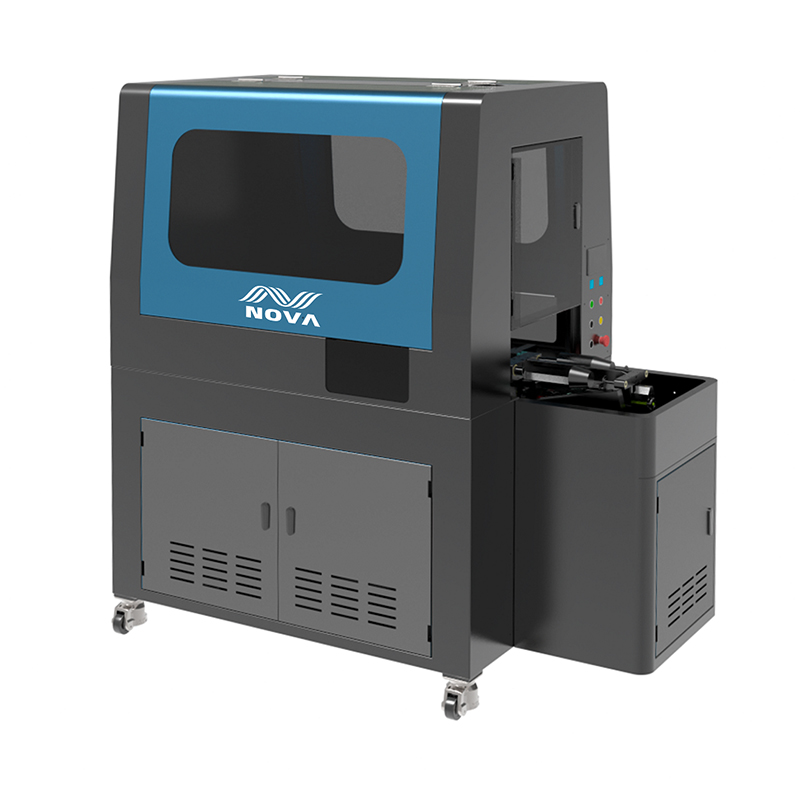

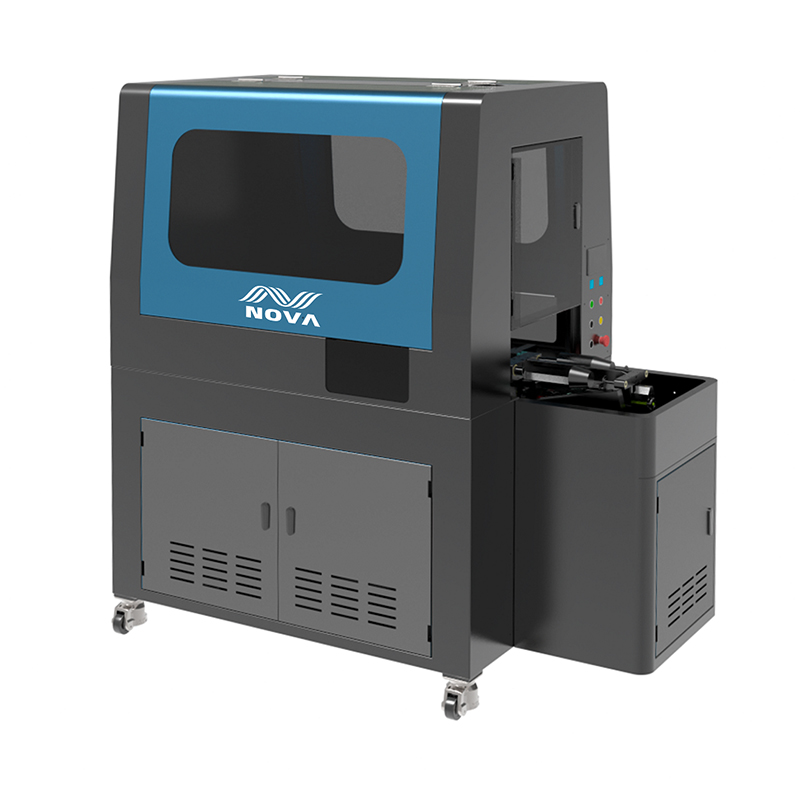

Xiamen Luhua jie Digital Technology Co., Ltd. presents its high-performance inkjet printer for beverage bottles, a specialized solution designed to meet the unique printing needs of the beverage industry. Beverage bottles come in a wide range of materials, including PET, glass, aluminum, and HDPE, and require printing that is not only visually appealing but also durable enough to withstand the rigors of production, transportation, storage, and consumer use. This inkjet printer for beverage bottles leverages advanced one-pass and AI scanning inkjet technologies to deliver exceptional results on various bottle surfaces. It supports high-resolution printing, enabling the reproduction of intricate logos, brand graphics, nutritional information, batch codes, and expiration dates with stunning clarity. The use of food-grade inks ensures compliance with strict industry regulations, making it suitable for printing on bottles containing carbonated drinks, juices, water, and other beverages. One of the key advantages of this printer is its versatility. It can handle bottles of different shapes and sizes, including cylindrical, square, and irregularly shaped bottles, and can accommodate various neck sizes and label positions. The printer's AI scanning technology allows for real-time detection of bottle positioning and surface variations, ensuring that the print is aligned correctly and of consistent quality across all bottles. In terms of durability, the printer's inks are formulated to resist fading, smudging, and scratching, even when exposed to moisture, refrigeration, or sunlight. This ensures that the printed information and branding remain intact throughout the product's lifecycle. With its high-speed printing capabilities, this inkjet printer for beverage bottles can keep up with fast-paced production lines, increasing productivity and reducing time-to-market. It is also designed for easy integration with existing production systems, minimizing downtime and operational costs.