Kosdoeltreffende bedrywing vir volhoubare winsgewendheid

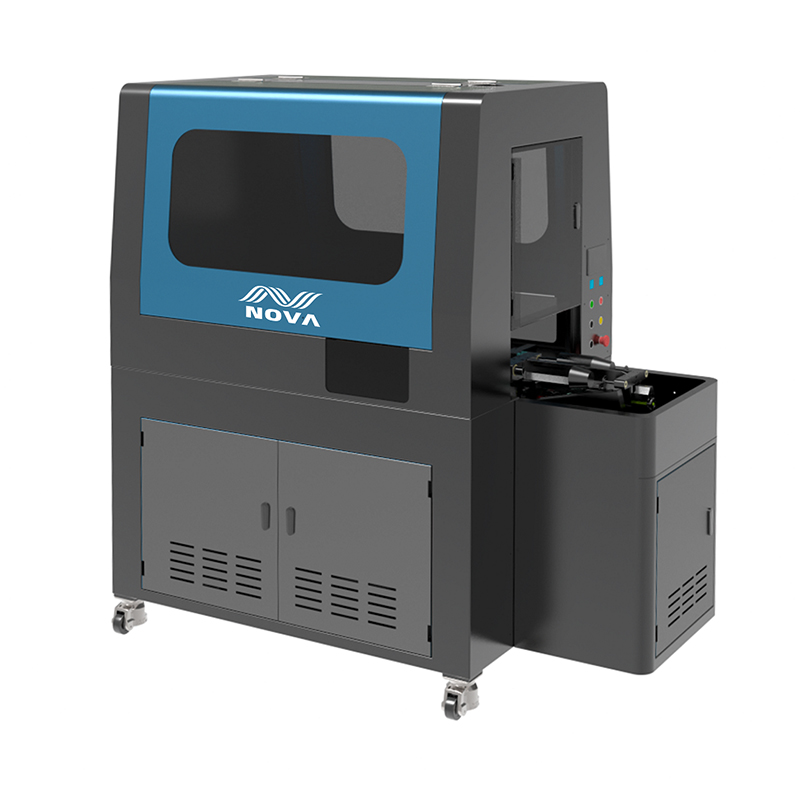

In die wenende handel van botteling hang 'n opmerklike bottelonderneming af van koste-effektiewe oplossings, en ons bottelinkjetdrukkers is daarin geen uitkomst nie. Eerstens word die krag- en energie-verbruik van ons drukkers geoptimeer, wat beteken dat hulle minder energie verbruik sonder om prestasie te sak. Tweedens word die ink-verbruik ook geoptimeer, wat beteken dat jy minder ink gebruik met elke druk, wat kosbesparing bring in die langer terme. Hierdie drukkers het ook 'n duurzaam bou, 'n lang lewe span wat beteken dat hulle minder gereelde onderhoud en vervangingsdele sal vereis nie. Al hierdie faktore saam help tot 'n lagere totale eienaarskoste, wat jou toelaat om gesonde winsmarges te handhaaf terwyl jy hoë gehalte gedrukte bottels produseer.