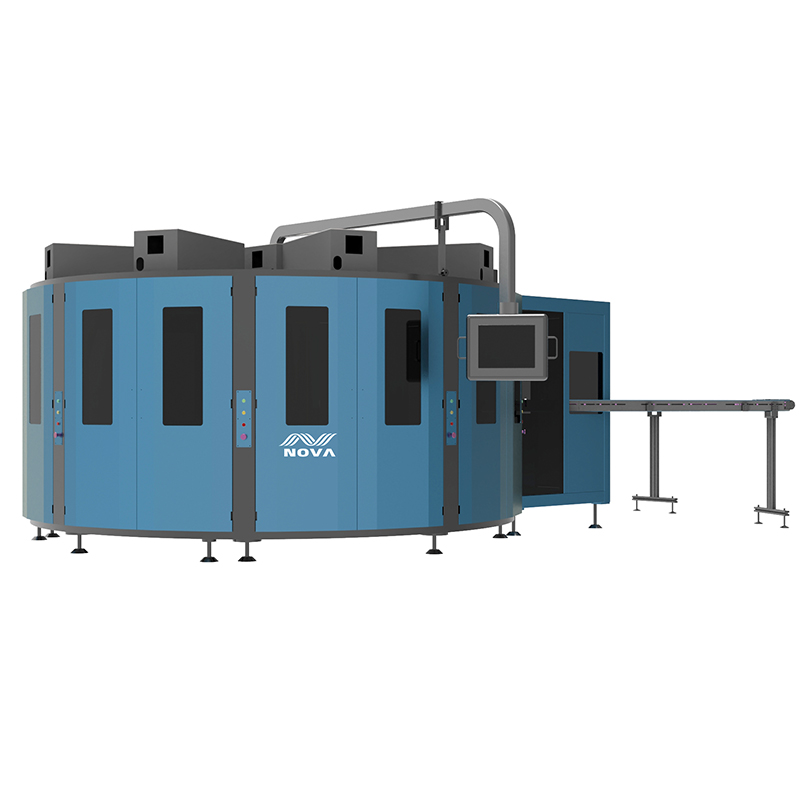

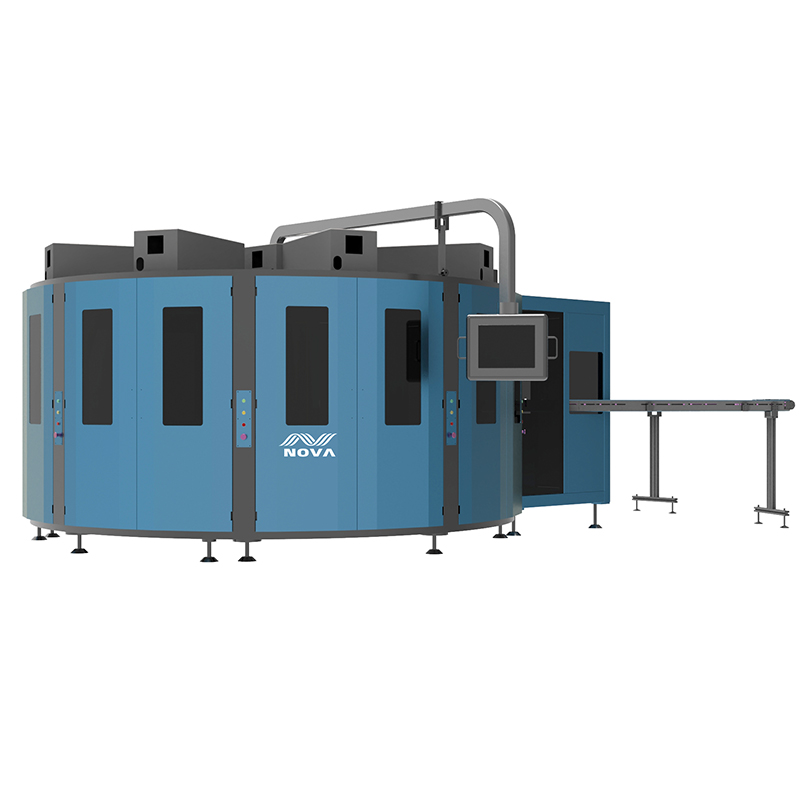

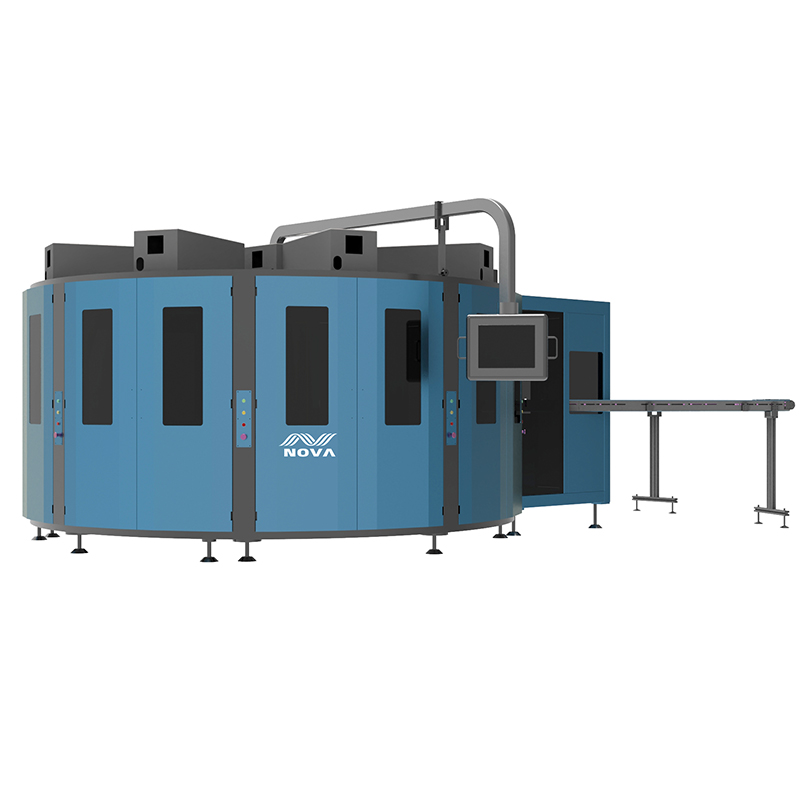

Неверогодна глибина кольору за допомогою декількох колірних екранів

Друкарня вражує на обох професійному та художньому рівнях. Кожен з її компонентів великою мірою сприяє її загальному рівню. Використання багатокольорового обертального екранного друку — головна особливість. Завдяки наявності кількох екранів для різних кольорів, кожен колір може наноситися одночасно без очікування, поки попередній не висохне. Кожен екран дозволяє нанести конкретний колір, і завдяки цьому можна одночасно нанести багато кольорів на різних рівнях, що призводить до друків небувалої складності та глибини кольору. Екрани мають можливість наносити різні пастельні відтінки, а також яскраві та живописні кольори з прикладним точністю. Незалежно від того, чи створюється ландшафт на стінних паперях, чи шьється модна одяг, багатокольорові екрани забезпечують те, що кожен друк є майстром з винятковим рівнем занадто складно поясненої кольорової вартості в порівнянні з іншими методами друку.