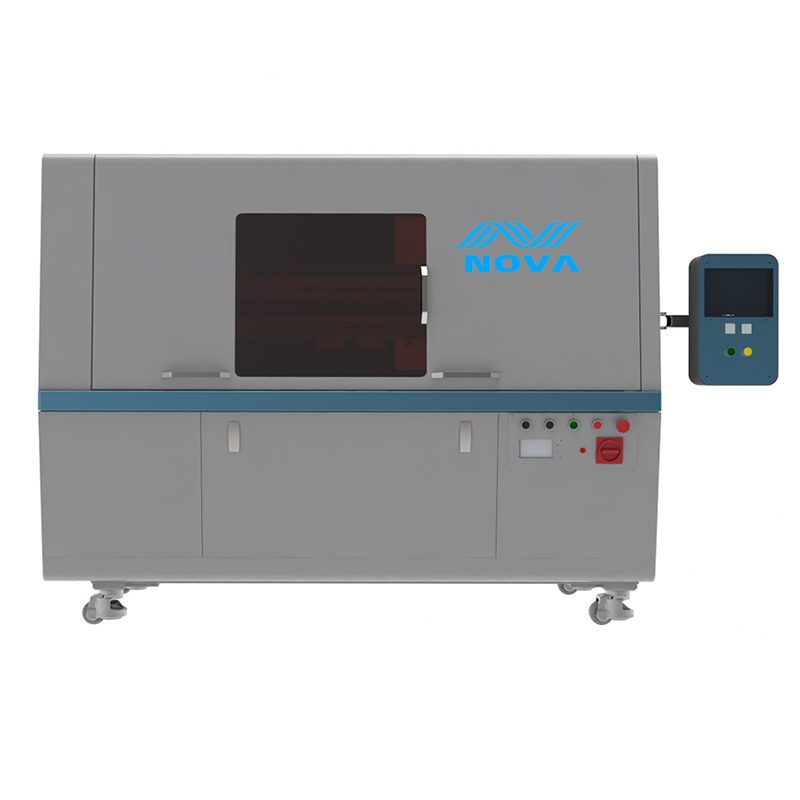

For businesses engaged in plastic product manufacturing and processing, the single pass uv inkjet printer for plastics from Xiamen Luhuajie Digital Technology Co., Ltd. is a game-changer. This specialized printer is engineered to address the unique challenges of printing on plastic surfaces, which often have smooth, non-porous characteristics that can make traditional printing methods less effective. The single pass technology of this printer ensures that the plastic products are printed in a single pass, significantly increasing production speed compared to multi-pass printers. This is especially beneficial for large-scale production, where time is of the essence. The UV curing system is another key feature – the ink is instantly cured upon exposure to UV light, resulting in quick drying and strong adhesion to plastic surfaces. This eliminates the problem of ink smearing or transferring, even immediately after printing. The printer uses high-quality UV inks that are designed to be compatible with various plastic materials, such as PVC, PET, PP, and PE. These inks offer excellent color vibrancy and clarity, making logos, graphics, and text stand out on plastic products. They also provide good resistance to chemicals, water, and abrasion, ensuring that the printed designs remain intact and attractive for a long time. Whether you are printing on plastic containers, toys, or promotional items, this printer delivers consistent and high-quality results. In addition to its performance advantages, the single pass uv inkjet printer for plastics is also highly flexible. It can accommodate different sizes and shapes of plastic products, thanks to its adjustable printing parameters and advanced feeding systems. The integration of modern control software allows for easy design customization and precise positioning of the printed content. This flexibility makes it suitable for both standard and custom plastic printing projects, helping businesses meet the ever-changing demands of the market. With this printer, you can achieve efficient, high-quality, and durable printing on plastics, giving your products a competitive edge.