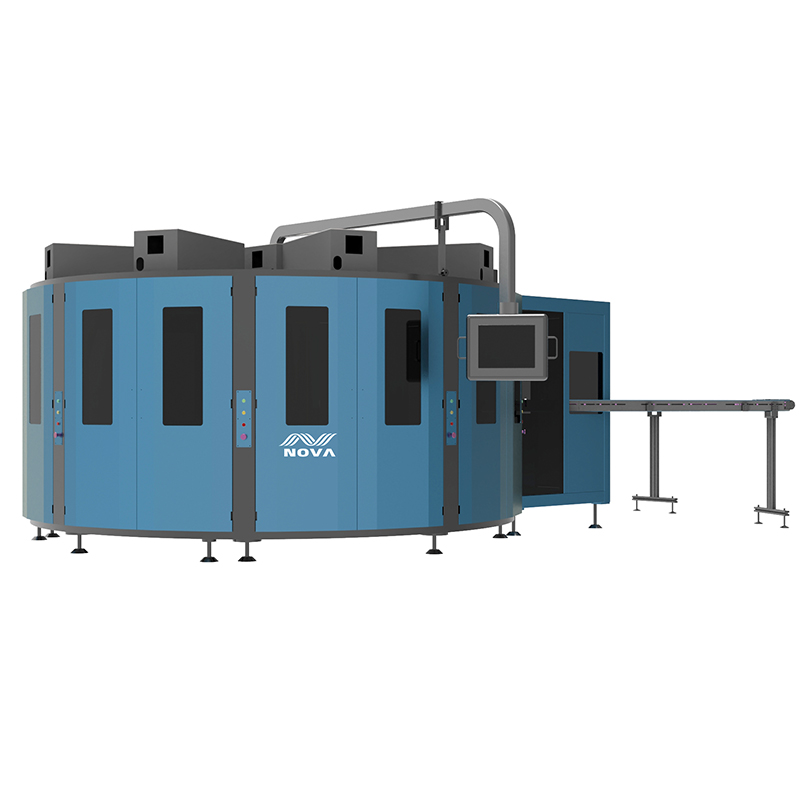

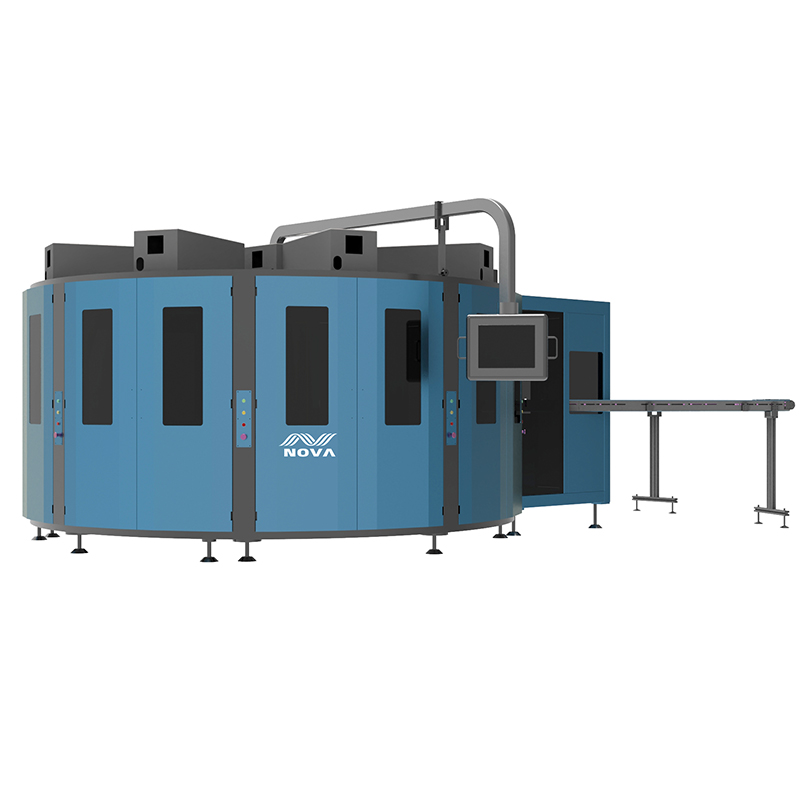

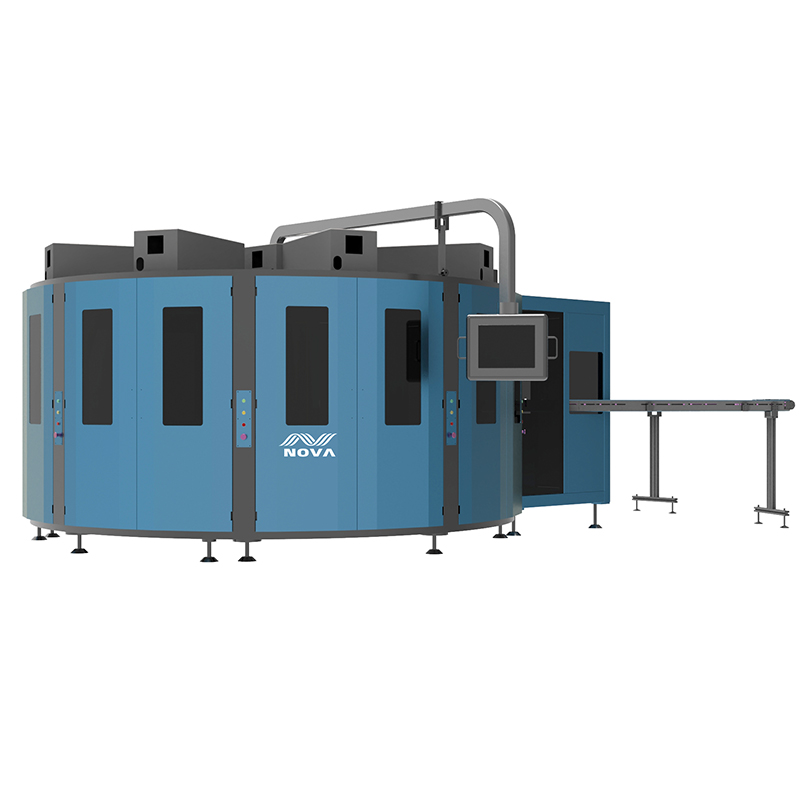

The multi colors cosmetic packaging rotary screen printer is a specialized printing solution designed to meet the unique aesthetic and functional requirements of the cosmetic industry. Cosmetic packaging demands high-quality, visually appealing prints that reflect the luxury and sophistication of the products they contain, and this printer delivers exactly that with its multi-color capabilities and precise rotary screen technology. The cosmetic industry relies heavily on packaging to attract customers and convey brand identity, making the appearance of packaging a critical factor in product success. Our multi colors cosmetic packaging rotary screen printer is engineered to reproduce vibrant, rich colors with exceptional accuracy, allowing businesses to create packaging that stands out on the shelves. Whether printing on glass bottles, plastic containers, or metal tubes, it delivers smooth, even prints with sharp details, ensuring that logos, product names, and decorative designs are displayed beautifully. The rotary screen mechanism of the printer ensures that prints are consistent across large production runs, a key requirement for maintaining brand consistency in the cosmetic industry. It can handle a variety of packaging shapes and sizes, from small lipstick cases to large perfume bottles, with ease, thanks to its flexible substrate handling capabilities. The multi-color configuration allows for the creation of complex, eye-catching designs, including gradients, metallic finishes, and intricate patterns, which are often used in cosmetic packaging to enhance visual appeal. In addition to its aesthetic capabilities, the printer is designed to produce durable prints that can withstand the rigors of the cosmetic industry, including exposure to moisture, oils, and handling. This ensures that the packaging remains attractive throughout the product’s lifecycle. With its focus on quality, versatility, and precision, the multi colors cosmetic packaging rotary screen printer is an essential tool for cosmetic brands looking to create packaging that elevates their products and captures the attention of consumers.